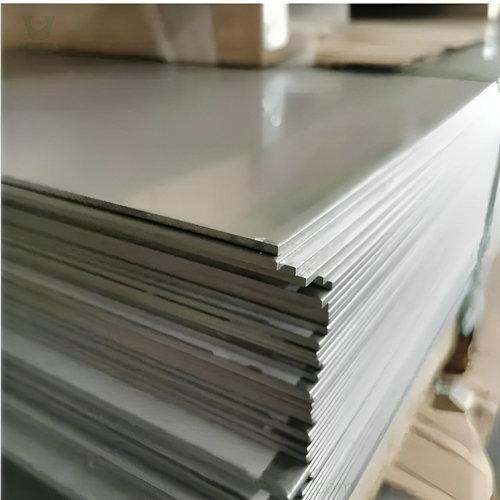

201 stainless steel sheets undergo various surface treatments and decorations to enhance their appearance, improve corrosion resistance, and meet specific application requirements. Here are some common surface treatments and decorations for 201 stainless steel sheets:

1. No. 1 Finish 201 stainless steel sheet: This is a hot-rolled, annealed, and descaled finish. While not decorative, it is suitable for applications where appearance is not critical.

2. No. 2D Finish 201 stainless steel sheet: A uniform, dull silver-gray surface resulting from cold rolling followed by annealing in an oxygen-free atmosphere. Commonly used for deep-drawn components.

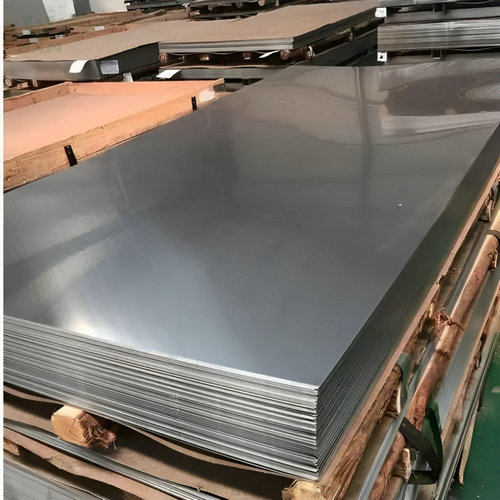

3. No. 2B Finish 201 stainless steel sheet: A bright, cold-rolled finish with a smooth, reflective appearance. Suitable for various architectural and industrial uses.

4. No. 3 Finish 201 stainless steel sheet: Achieved by using successively finer abrasives and buffing extensively. Provides a smooth, reflective surface.

5. No. 4 Finish 201 stainless steel sheet: Also known as a satin finish, it has a brushed appearance that hides surface imperfections. Widely used for decorative applications.

6. BA (Bright Annealed) Finish 201 stainless steel sheet: Produced by annealing in a controlled atmosphere furnace, resulting in a reflective, mirror-like surface. Suitable for decorative applications.

7. Embossing 201 stainless steel sheet: The surface of the stainless steel sheet is patterned with a raised design. Embossed patterns can add both visual appeal and increased grip.

8. Etching 201 stainless steel sheet: Chemical etching creates intricate patterns or designs on the surface, often used for decorative applications.

9. PVD Coating 201 stainless steel sheet: Physical Vapor Deposition applies a thin film of material onto the surface, providing color and additional corrosion protection.

10. Laser Cutting 201 stainless steel sheet: Laser cutting technology creates precise and intricate designs on the surface, suitable for branding or artistic patterns.

11. Colored Finishes 201 stainless steel sheet: Various colored finishes, applied through processes like powder coating or electroplating, allow customization to match specific design requirements.

12. Anti-Fingerprint Coating 201 stainless steel sheet: Reduces the visibility of fingerprints and stains, maintaining a clean appearance.

13. Hairline Finish 201 stainless steel sheet: A finish achieved by polishing the surface with a fine abrasive, resulting in a consistent, unidirectional appearance.

14. Vibration Finish 201 stainless steel sheet: A textured finish created through mechanical processes, offering a unique visual effect.

These surface treatments and decorations contribute to the aesthetic appeal, functionality, and durability of 201 stainless steel sheets. The choice depends on the intended use, design preferences, and the desired level of corrosion resistance.