416 stainless steel sheets

Excellent and advantageous Stainless steel supplier in China——Huaxiao Metal

Unleash the power of 416 stainless steel sheets, a material that epitomizes exceptional strength and versatility. Renowned for its robust properties, 416 stainless steel sheets offer unparalleled performance in the most demanding environments. With its outstanding corrosion resistance, high tensile strength, and impressive machinability, 416 stainless steel sheets stand as a top choice for various industries. Whether you’re seeking durability in aerospace applications or precision in manufacturing processes, 416 stainless steel sheets deliver unparalleled reliability and endless possibilities. Embark on a journey to explore the remarkable characteristics of 416 stainless steel sheets and witness a material that takes your projects to new heights of excellence.

Hardness (Rockwell C): 26-32

Tensile Strength: 580-760 MPa

Yield Strength: 415 MPa

Elongation: 20%

Density: 7.75 g/cm³

Melting Range: 1450-1500°C

Magnetic Properties: Magnetic

Corrosion Resistance: Moderate

Machinability: Excellent

12-14% Chromium

0.15% Carbon

1.25% Manganese

1.0% Silicon

0.06% Phosphorus

0.15% Sulfur

with the remaining being Iron

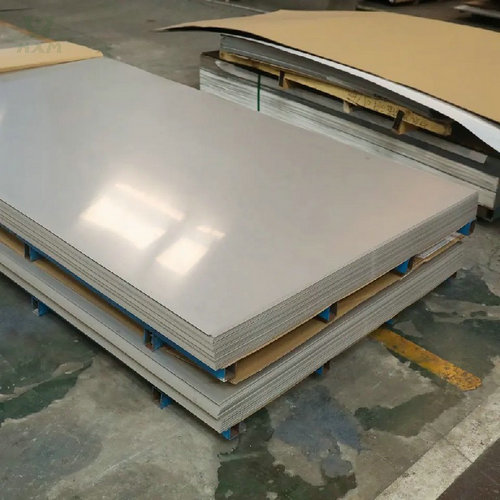

Thickness: 0.5mm, 1.0mm, 1.5mm, 2.0mm, 3.0mm

Width: 1000mm

Length: 2000mm, 6000mm

Please note that these are just some common options, and there may be other sizes and custom options available. Specific specifications may vary depending on the supplier.

Contents

How does the composition of 416 stainless steel sheets contribute to their performance?

The composition of 416 stainless steel sheets plays a crucial role in determining their performance and properties. In this article, we will explore how the specific composition of 416 stainless steel influences its characteristics and why it is a preferred material for various applications. Additionally, we will discuss the importance of choosing reliable stainless steel suppliers for obtaining high-quality 416 stainless steel sheets.

What is the composition of 416 stainless steel? The composition of 416 stainless steel typically includes carbon, manganese, phosphorus, sulfur, silicon, chromium, and sometimes molybdenum. The exact composition may vary depending on the specific grade and manufacturing process.

How does the carbon content affect the properties of 416 stainless steel sheets? The carbon content in 416 stainless steel enhances its hardness, strength, and machinability. Higher carbon content promotes greater hardness, making it suitable for applications requiring wear resistance and high mechanical performance.

What is the role of chromium in 416 stainless steel composition? Chromium is a key element in stainless steel, including 416 grade. It provides excellent corrosion resistance, making 416 stainless steel sheets resistant to many chemicals, atmospheric conditions, and mild acids.

How does sulfur impact the machinability of 416 stainless steel? Sulfur is added to 416 stainless steel to improve its machinability. The presence of sulfur creates free-machining characteristics, allowing for easier cutting, drilling, and shaping processes.

What are the mechanical properties of 416 stainless steel sheets? 416 stainless steel exhibits excellent tensile strength, hardness, and impact resistance. It has good toughness and can withstand moderate to high temperatures, making it suitable for various industrial applications.

What are the corrosion resistance properties of 416 stainless steel sheets? While 416 stainless steel offers good corrosion resistance, it is not as corrosion-resistant as other stainless steel grades, such as 304 or 316. It is more prone to surface rusting in certain corrosive environments. Therefore, it is important to consider the specific application and environment when selecting 416 stainless steel sheets.

How does the composition of 416 stainless steel contribute to its heat treatment capabilities? The composition of 416 stainless steel allows for heat treatment processes, such as annealing, hardening, and tempering, to modify its mechanical properties. Heat treatment can further enhance its hardness, strength, and toughness as per specific application requirements.

Why is it important to choose reliable stainless steel suppliers for 416 stainless steel sheets? To ensure the quality and performance of 416 stainless steel sheets, it is crucial to source them from reputable stainless steel suppliers. Reliable suppliers adhere to strict quality control measures, provide certifications, and offer technical support, ensuring that the material meets the required specifications.

Conclusion: The composition of 416 stainless steel sheets significantly influences their performance and properties. The specific levels of carbon, chromium, sulfur, and other elements contribute to its hardness, machinability, corrosion resistance, and heat treatment capabilities. When selecting 416 stainless steel sheets, it is important to consider the specific application requirements and source them from reliable stainless steel suppliers to ensure the highest quality and performance.

What are the machinability characteristics of 416 stainless steel sheets?

In this article, we will explore the machinability characteristics of 416 stainless steel sheets. Machinability refers to the ease with which a material can be machined or shaped using various machining processes. Understanding the machinability of 416 stainless steel is crucial for industries that rely on efficient and precise machining operations. We will discuss the factors that contribute to the machinability of 416 stainless steel and why it is a preferred choice for machined components. Additionally, we will highlight the importance of selecting reputable stainless steel suppliers for obtaining high-quality 416 stainless steel sheets.

What is the composition of 416 stainless steel and how does it impact machinability? 416 stainless steel contains higher sulfur content, which enhances its machinability. The sulfur acts as a lubricant during machining, reducing friction and heat generation. Additionally, the presence of sulfur promotes the formation of small, brittle chips, resulting in better chip control and improved machinability.

How does the heat treatment of 416 stainless steel affect its machinability? Heat treatment processes, such as annealing or hardening, can affect the machinability of 416 stainless steel. Proper heat treatment can optimize the material’s microstructure, resulting in improved machinability characteristics.

What are the cutting tool considerations when machining 416 stainless steel sheets? When machining 416 stainless steel, it is important to use cutting tools specifically designed for stainless steel alloys. Carbide or high-speed steel tools with appropriate coatings are commonly used to ensure efficient cutting and prolonged tool life.

What machining processes are suitable for 416 stainless steel sheets? 416 stainless steel sheets can be machined using various processes such as turning, milling, drilling, and threading. The material’s machinability allows for high-speed machining operations, making it suitable for applications that require rapid production and precision machining.

How does the machinability of 416 stainless steel compare to other stainless steel grades? Compared to other stainless steel grades, such as austenitic stainless steels (e.g., 304, 316), 416 stainless steel offers better machinability. The higher sulfur content in 416 stainless steel provides improved chip control and reduced tool wear during machining operations.

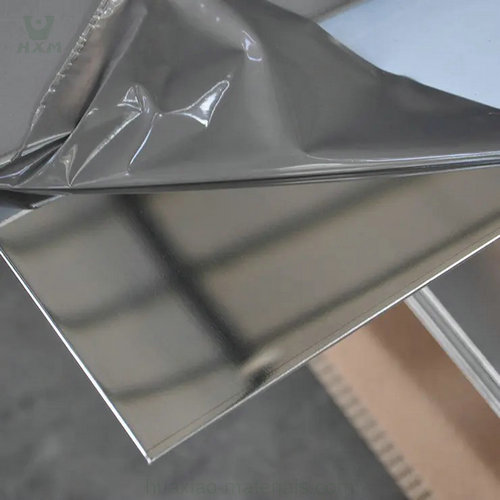

What are the surface finish considerations when machining 416 stainless steel sheets? Proper machining techniques and cutting parameters should be employed to achieve desired surface finishes. Post-machining processes like grinding or polishing can further enhance the surface finish of 416 stainless steel components.

Why is 416 stainless steel a preferred choice for machined components? The excellent machinability of 416 stainless steel makes it a preferred material for machined components in various industries. Its ease of machining allows for faster production rates, reduced production costs, and improved productivity.

Why is it important to choose reliable stainless steel suppliers for 416 stainless steel sheets? Selecting reputable stainless steel suppliers is essential to ensure the quality and machinability of 416 stainless steel sheets. Reliable suppliers offer certified materials with consistent composition and provide technical support, ensuring optimal machinability and performance.

Conclusion: The machinability characteristics of 416 stainless steel sheets make it a favored choice for industries that require efficient and precise machining operations. The higher sulfur content in its composition improves chip control, reduces friction, and enhances tool life. Machining processes such as turning, milling, drilling, and threading can be employed to shape 416 stainless steel sheets. Selecting reputable stainless steel suppliers is crucial for obtaining high-quality material with consistent machinability. By understanding the machinability characteristics of 416 stainless steel, industries can optimize their machining operations and achieve superior results.

Are there specific industries that prefer using 416 stainless steel sheets?

In this article, we will explore the specific industries that prefer using 416 stainless steel sheets. 416 stainless steel offers a unique set of properties that make it suitable for various applications. Understanding these industries can help in identifying the specific requirements and benefits associated with using 416 stainless steel sheets. Additionally, we will highlight the importance of reliable stainless steel suppliers in meeting the industry-specific demands for high-quality 416 stainless steel sheets.

Aerospace Industry:

The aerospace industry often utilizes 416 stainless steel sheets due to their excellent strength, corrosion resistance, and machinability. Components such as aircraft fittings, fasteners, and engine parts benefit from the material’s high tensile strength and resistance to atmospheric conditions.

Automotive Industry:

In the automotive sector, 416 stainless steel sheets find applications in components requiring high strength, durability, and resistance to corrosion. Examples include exhaust systems, valves, and engine components that are subjected to high temperatures and harsh environmental conditions.

Medical and Surgical Instruments:

416 stainless steel sheets are commonly used in the manufacturing of medical and surgical instruments. The material’s corrosion resistance, biocompatibility, and ease of machining make it suitable for instruments such as surgical knives, forceps, and dental tools.

Firearms and Defense Industry:

The firearms and defense industry frequently employs 416 stainless steel sheets for firearm components and defense equipment. The material’s strength, hardness, and resistance to corrosion are highly desirable for applications where durability, reliability, and performance are critical.

Food Processing and Packaging:

416 stainless steel sheets are utilized in the food processing and packaging industry due to their hygienic properties and resistance to corrosion caused by food acids and environments. Equipment such as blades, knives, and food processing machinery components benefit from the material’s machinability and corrosion resistance.

Petrochemical Industry:

In the petrochemical industry, 416 stainless steel sheets are preferred for their resistance to corrosive chemicals and high temperatures. Components like valves, fittings, and pump shafts require the material’s excellent mechanical properties and resistance to chemical environments.

Marine and Offshore Industry:

416 stainless steel sheets find applications in the marine and offshore industry, where corrosion resistance is crucial due to exposure to saltwater and harsh marine environments. Components such as marine hardware, boat fittings, and offshore platform structures benefit from the material’s resistance to pitting and crevice corrosion.

Tool and Die Industry:

The tool and die industry relies on 416 stainless steel sheets for manufacturing cutting tools, dies, and molds. The material’s high hardness, wear resistance, and machinability make it ideal for producing precision tools that require prolonged durability and consistent performance.

Conclusion: Several industries prefer using 416 stainless steel sheets due to their unique combination of properties, including strength, corrosion resistance, and machinability. The aerospace, automotive, medical, firearms, food processing, petrochemical, marine, offshore, and tool and die industries are among the key sectors that benefit from the use of 416 stainless steel sheets. Reliable stainless steel suppliers play a crucial role in meeting the industry-specific demands for high-quality material. By understanding the preferences and requirements of these industries, manufacturers and suppliers can effectively cater to their needs and deliver optimal solutions using 416 stainless steel sheets.

What are the common applications of 416 stainless steel sheets?

In this article, we will explore the common applications of 416 stainless steel sheets. 416 stainless steel offers a unique combination of properties that make it suitable for various industries and applications. Understanding these applications can help in identifying the versatility and benefits associated with using 416 stainless steel sheets. Additionally, we will highlight the importance of reliable stainless steel suppliers in meeting the diverse demands for high-quality 416 stainless steel sheets.

Machining and Tooling:

416 stainless steel sheets are widely used in the machining and tooling industry due to their excellent machinability and wear resistance. They are commonly employed in the production of components such as gears, bolts, screws, and shafts, where high strength, hardness, and dimensional stability are required.

Firearms and Weaponry:

The firearms and weaponry industry extensively utilizes 416 stainless steel sheets for manufacturing gun barrels, receivers, and other firearm components. The material’s strength, corrosion resistance, and ability to withstand high-pressure environments make it a preferred choice for ensuring reliable and durable firearms.

Automotive Components:

416 stainless steel sheets find applications in the automotive industry for manufacturing components such as valves, gears, and fittings. The material’s excellent strength, corrosion resistance, and ability to withstand high temperatures make it suitable for critical engine parts and exhaust systems.

Food Processing Equipment:

Due to its good corrosion resistance and hygienic properties, 416 stainless steel sheets are commonly used in the food processing industry. Equipment such as knives, blades, mixers, and food packaging machinery benefit from the material’s resistance to food acids and its ease of cleaning and maintenance.

Medical and Surgical Instruments:

416 stainless steel sheets are widely employed in the medical and surgical instrument industry. The material’s biocompatibility, corrosion resistance, and ease of sterilization make it suitable for producing surgical instruments, dental tools, and implants.

Marine and Coastal Applications:

In marine and coastal environments, 416 stainless steel sheets are utilized for applications such as boat fittings, marine hardware, and coastal structures. The material’s corrosion resistance and ability to withstand exposure to saltwater and harsh marine conditions make it an ideal choice.

Petrochemical Industry:

416 stainless steel sheets are used in the petrochemical industry for manufacturing components such as valves, pumps, and fittings. The material’s resistance to corrosive chemicals and high temperatures ensures reliable performance in demanding petrochemical environments.

General Purpose Applications:

416 stainless steel sheets find widespread use in general-purpose applications, including construction, industrial equipment, and machinery. Their excellent combination of strength, corrosion resistance, and machinability makes them suitable for a wide range of applications.

Conclusion: 416 stainless steel sheets are versatile and find applications in various industries and sectors. Common applications include machining and tooling, firearms and weaponry, automotive components, food processing equipment, medical and surgical instruments, marine and coastal applications, petrochemical industry, and general-purpose applications. Reliable stainless steel suppliers play a crucial role in meeting the diverse demands for high-quality 416 stainless steel sheets across these industries. By understanding the common applications, manufacturers and suppliers can effectively cater to the needs of their customers and deliver optimal solutions using 416 stainless steel sheets.

316 vs 416 stainless steel

In this article, we will delve into the key differences between two commonly used stainless steel grades: 416 stainless steel and 316 stainless steel. While both materials belong to the stainless steel family, they possess distinct compositions and properties that make them suitable for specific applications. By understanding these differences, customers can make informed decisions when selecting the appropriate stainless steel grade for their specific requirements. We will also highlight the importance of reliable stainless steel suppliers in providing high-quality materials to meet diverse industry needs.

Composition:

416 Stainless Steel:

- Contains a higher sulfur content and lower chromium and nickel content compared to 316 stainless steel.

- Composition: 0.15% maximum carbon, 12-14% chromium, 0.15% minimum sulfur, and the balance iron.

316 Stainless Steel:

- Contains a higher chromium and nickel content, providing enhanced corrosion resistance.

- Composition: 0.08% maximum carbon, 16-18% chromium, 10-14% nickel, 2-3% molybdenum, and the balance iron.

Corrosion Resistance:

416 Stainless Steel:

- Offers moderate corrosion resistance compared to 316 stainless steel.

- Suitable for applications in mildly corrosive environments.

316 Stainless Steel:

- Exhibits excellent corrosion resistance, particularly in chloride-rich environments.

- Ideal for applications exposed to harsh corrosive conditions, such as marine or coastal environments.

Mechanical Properties:

416 Stainless Steel:

- Known for its excellent machinability due to the sulfur content.

- Provides good strength, hardness, and wear resistance.

- Not as ductile as 316 stainless steel.

316 Stainless Steel:

- Offers good strength and excellent ductility.

- Provides superior corrosion resistance and toughness.

- Less machinable compared to 416 stainless steel due to its higher alloy content.

Heat Resistance:

416 Stainless Steel:

- Displays moderate heat resistance.

- Suitable for applications involving moderate temperatures.

316 Stainless Steel:

- Exhibits excellent heat resistance.

- Ideal for high-temperature applications, such as heat exchangers and exhaust systems.

Applications:

416 Stainless Steel:

- Commonly used in applications requiring high machinability, such as screws, bolts, nuts, and bushings.

- Also utilized in valve components, pump shafts, and firearm parts.

316 Stainless Steel:

- Widely employed in industries where superior corrosion resistance is essential, including marine, chemical, and food processing industries.

- Used for equipment such as tanks, pipes, fittings, and surgical instruments.

Conclusion: Understanding the key differences between 416 stainless steel and 316 stainless steel is crucial for selecting the appropriate material for specific applications. While 416 stainless steel offers excellent machinability and moderate corrosion resistance, 316 stainless steel provides superior corrosion resistance and heat resistance. Reliable stainless steel suppliers play a vital role in providing high-quality materials that meet industry demands. By considering the composition, corrosion resistance, mechanical properties, heat resistance, and applications of these two stainless steel grades, customers can make informed decisions and ensure optimal performance in their respective applications.

How do I choose a reliable supplier for 416 stainless steel sheets?

When it comes to procuring 416 stainless steel sheets, selecting a reliable supplier is crucial to ensure the quality and performance of the material. In this article, we will explore the key factors to consider when choosing a supplier for 416 stainless steel sheets. By understanding these factors, customers can make informed decisions and establish partnerships with trusted suppliers who can meet their specific requirements.

Reputation and Experience:

Look for suppliers with a strong reputation and extensive experience in the stainless steel industry. A reputable supplier is more likely to provide high-quality 416 stainless steel sheets and reliable customer service. Check their track record, customer reviews, and industry certifications to assess their credibility.

Material Quality and Traceability:

Ensure that the supplier offers 416 stainless steel sheets of superior quality. Ask about their quality control processes, certifications, and adherence to industry standards. Traceability of the material is also essential to guarantee its authenticity and compliance with specifications.

Wide Range of Products:

Choose a supplier that offers a diverse range of 416 stainless steel sheets in various dimensions, thicknesses, and finishes. This ensures that you have access to a comprehensive selection that suits your specific project requirements.

Customization Capabilities:

If you have unique specifications or require customized 416 stainless steel sheets, opt for a supplier with the capability to meet your customization needs. This includes the ability to provide tailored dimensions, surface finishes, and additional services like cutting, machining, or fabrication.

Timely Delivery and Logistics Support:

Efficient delivery and logistics support are crucial to avoid project delays. Choose a supplier with a robust distribution network and a track record of timely deliveries. Consider their shipping options, lead times, and ability to handle your desired order volume.

Competitive Pricing:

While quality is paramount, it is essential to find a supplier who offers competitive pricing for 416 stainless steel sheets. Request quotes from multiple suppliers and compare their prices, taking into account factors such as material quality, customization options, and additional services offered.

Technical Support and Expertise:

A reliable supplier should have a knowledgeable team that can provide technical support and guidance. They should be able to assist with material selection, application-specific recommendations, and answer any queries regarding 416 stainless steel composition and properties.

Customer Service:

Evaluate the supplier’s commitment to customer satisfaction. Consider their responsiveness, communication channels, and willingness to address any concerns or issues that may arise during the procurement process.

Conclusion: Choosing a reliable supplier for 416 stainless steel sheets is crucial to ensure the quality, availability, and timely delivery of the material. Consider factors such as reputation, material quality, customization capabilities, pricing, technical support, and customer service when making your decision. By partnering with a reputable supplier, you can have confidence in the quality and performance of your 416 stainless steel sheets, ultimately contributing to the success of your projects.

Conclusion:

Answer: The composition of 416 stainless steel sheets, including higher levels of sulfur and phosphorus, as well as added copper and phosphorus, provides good machinability and wear resistance but can have some impact on their corrosion resistance.

Answer: 416 stainless steel sheets exhibit excellent machinability, including good cutting, shearing, and drilling characteristics, making them an ideal choice for applications that involve challenging machining operations.

Answer: 416 stainless steel sheets are extensively used in industries such as food processing, medical equipment, automotive components, and aerospace, particularly in areas that require good wear resistance and machinability.

Answer: 416 stainless steel sheets are commonly used in the manufacturing of high-strength, wear-resistant parts such as blades, bearings, valves, bolts, and nuts, as well as components and machinery parts that operate in high-temperature environments.

Answer: Compared to 316 stainless steel, 416 stainless steel has higher hardness, magnetic properties, and machinability, but relatively lower corrosion resistance, making them suitable for different application scenarios and working environments.

Answer: When selecting a reliable supplier for 416 stainless steel sheets, factors to consider include the supplier’s reputation, product quality, customization capabilities, competitive pricing, technical support, and customer service.

In summary, the composition of 416 stainless steel sheets significantly influences their performance. The high sulfur content enhances machinability, making them suitable for applications that require extensive machining operations. These sheets offer excellent corrosion resistance, moderate strength, and good mechanical properties. They find wide usage in industries such as aerospace, automotive, and manufacturing.

When comparing 416 stainless steel to 316 stainless steel, notable differences arise in terms of composition, corrosion resistance, and heat resistance. While 316 stainless steel excels in corrosive environments, 416 stainless steel is preferred for applications that require improved machinability and wear resistance.

To ensure the procurement of high-quality 416 stainless steel sheets, it is essential to select a reliable supplier. Factors to consider include the supplier’s reputation, certifications, quality control processes, and ability to provide customized solutions. A reputable supplier will offer superior products, technical support, on-time delivery, and excellent customer service.

By understanding the properties, applications, and supplier selection criteria, individuals can make informed decisions when purchasing 416 stainless steel sheets, ensuring the fulfillment of their specific requirements.