The 4×8 feet size of stainless steel sheets is a standard dimension that caters to common industry standards and project needs in various applications. This size, also known as 48 inches by 96 inches, has become a widely accepted standard in the stainless steel industry for several reasons:

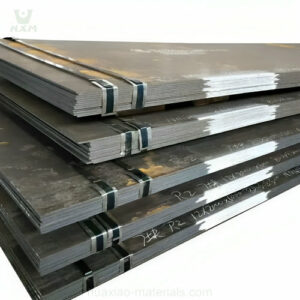

Versatility: The 4×8 feet size is versatile and can be easily adapted to fit various fabrication requirements. It offers a good balance between being large enough for many applications while still manageable for cutting, shaping, and transportation.

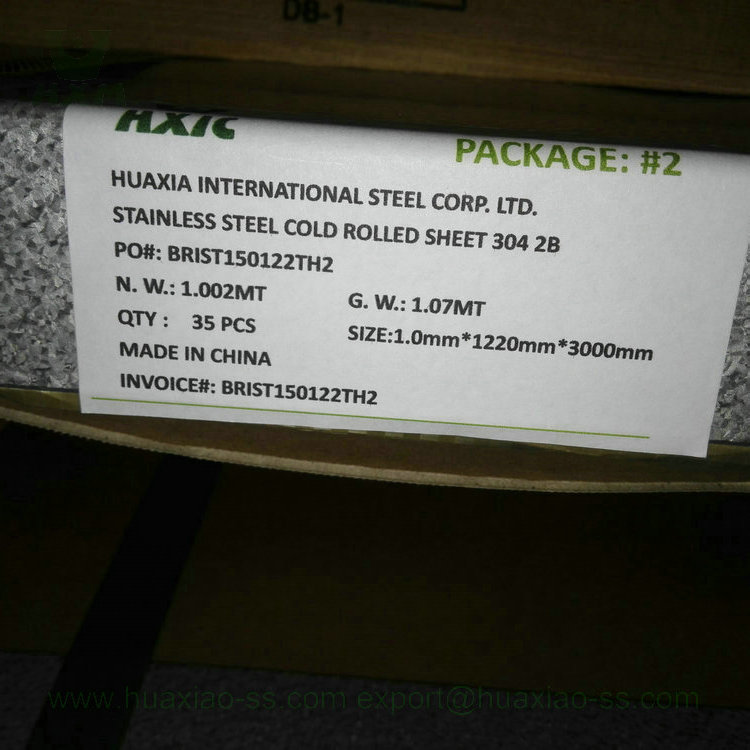

Common Stock Size: Many stainless steel suppliers offer 4×8 feet sheets as a common stock size. This availability makes it convenient for customers to source materials without the need for custom orders, which can be more time-consuming and costly.

Fabrication Efficiency: The 4×8 feet size is practical for common fabrication processes, such as cutting, bending, and welding. It can be efficiently used in manufacturing components for different industries, including construction, automotive, and manufacturing.

Standardization: Due to its widespread use, the 4×8 feet size aligns with industry standards and specifications. This standardization makes it easier for engineers, architects, and fabricators to plan and design projects that incorporate stainless steel sheets.

Cost-Effectiveness: Producing stainless steel sheets in the 4×8 feet size is cost-effective for manufacturers and suppliers. It optimizes material usage and minimizes waste, resulting in better pricing for customers.

Transportation and Storage: The 4×8 feet size is convenient for transportation and storage. It can be easily loaded onto trucks and containers, making logistics more efficient and cost-effective.

Availability of Accessories: Many accessories, such as hardware and fittings, are designed to work with the 4×8 feet size. This compatibility simplifies the integration of stainless steel sheets into various applications.

Compatibility with Construction Standards: In construction projects, the 4×8 feet size aligns well with standard dimensions used for walls, ceilings, countertops, and other architectural elements.

Renovation and Repair: For renovation and repair projects, the 4×8 feet size is practical because it matches existing building materials and allows for seamless replacements.

Easy Handling: The 4×8 feet size is manageable for one or two individuals to handle, reducing the need for specialized equipment during fabrication and installation.

Overall, the 4×8 feet size of stainless steel sheets provides a balance between practicality, availability, and efficiency, making it a preferred choice for a wide range of industries and applications. Whether in construction, manufacturing, or other sectors, this standard size contributes to streamlined processes and effective project execution.