Grade: 304 ,201,430,

Thickness: 0.3mm – 4.0mm

Width: 1000/1219/1500mm/customized

Length: 6000mm/coil

Film: Double PE/laser PE

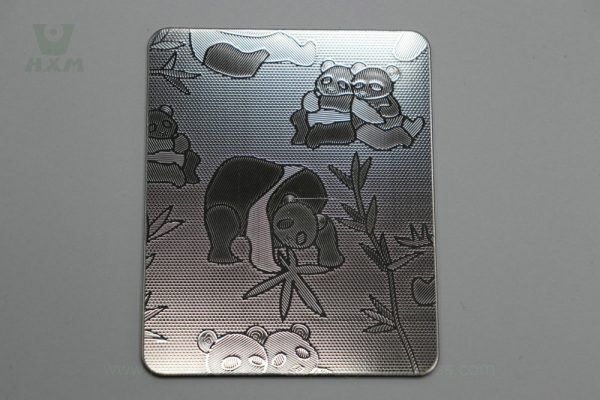

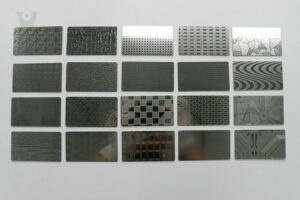

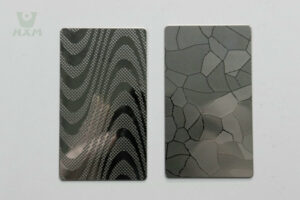

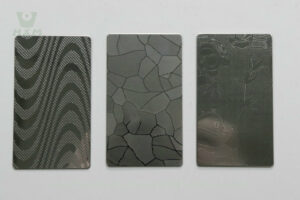

Pattern:

Leather 2B Mill Finish stainless steel,

Leather Rose Gold stainless steel,

Leather BA stainless steel,

Wood Brass stainless steel,

Linen BA stainless steel,

Linen Antique stainless steel,

Linen Brass stainless steel,

ICY Bamboo stainless steel,

Square embossed stainless steel,

6WL stainless steel,

5WL stainless steel