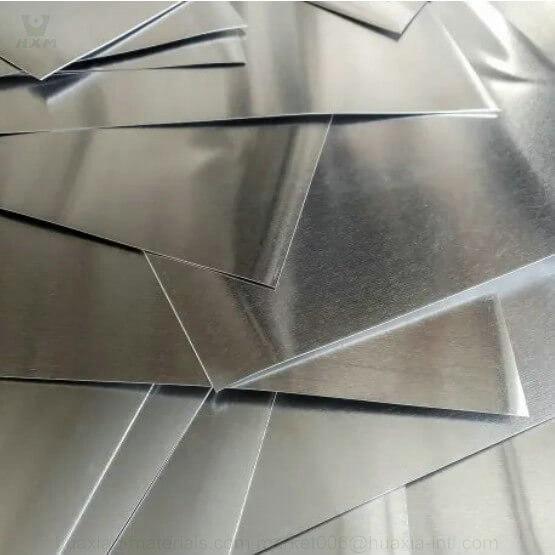

430 stainless steel sheet is a popular material known for its unique properties and wide range of applications. It belongs to the ferritic stainless steel family, characterized by its high chromium content and moderate corrosion resistance. The 430 stainless steel sheet offers excellent formability, making it suitable for various fabrication processes. It exhibits good mechanical properties, including high strength and hardness. Additionally, it possesses magnetic properties, which can be advantageous in certain applications. Due to its corrosion resistance, durability, and affordability, 430 stainless steel sheet finds applications in household appliances, automotive trim, kitchen utensils, and architectural components.

Corrosion Resistance:

430 stainless steel sheet exhibits good corrosion resistance, particularly against oxidizing and organic acids.

Strength and Hardness:

Due to its higher chromium content, 430 stainless steel sheet offers good strength and hardness.

Magnetism:

430 stainless steel sheet is magnetic and suitable for applications that require magnetic properties.

Processability:

It is easily processed and formed, suitable for various cold and hot working processes.

Temperature Tolerance:

It demonstrates good performance at high and low temperatures, allowing for use in different temperature environments.

Chromium (Cr): 16% to 18%

Manganese (Mn): Up to 1%

Silicon (Si): Up to 1%

Carbon (C): Up to 0.12%

Phosphorus (P): Up to 0.04%

Sulfur (S): Up to 0.03%

Iron (Fe): Remaining balance

Thickness: Typically ranging from 0.4 mm to 3.0 mm

Width: Typically ranging from 1000 mm to 1500 mm

Length: Customizable according to requirements

In this article, we will explore the specifications and dimensions available for 430 stainless steel sheets. As a widely used stainless steel grade, understanding the various options in terms of size and dimensions is essential for selecting the right product for specific applications. By examining the standard specifications and dimensions, as well as the offerings from stainless steel sheet suppliers, we can gain valuable insights into the range of options available in the market.

Chemical Composition: 430 stainless steel is a ferritic stainless steel grade with a composition typically consisting of 16-18% chromium and 0.12-0.75% nickel. It also contains small amounts of manganese, silicon, and carbon.

Tensile Strength: The tensile strength of 430 stainless steel sheets typically ranges from 450 to 600 MPa (megapascals).

Yield Strength: The yield strength of 430 stainless steel sheets is generally around 240-310 MPa.

Hardness: 430 stainless steel sheets typically exhibit a hardness range of 150 to 280 HB (Brinell hardness).

Corrosion Resistance: While 430 stainless steel offers good corrosion resistance in mildly corrosive environments, it is not as corrosion resistant as some other stainless steel grades, such as 304 or 316.

Magnetic Properties: 430 stainless steel is a magnetic material, which makes it suitable for applications where magnetic properties are desired.

Thickness: 430 stainless steel sheets are available in various thicknesses, typically ranging from 0.4 mm to 3.0 mm.

Width: The width of 430 stainless steel sheets can vary from 1,000 mm to 1,500 mm, depending on the specific product and supplier.

Length: The length of 430 stainless steel sheets is typically in the range of 2,000 mm to 6,000 mm. However, custom lengths can also be obtained from stainless steel sheet suppliers.

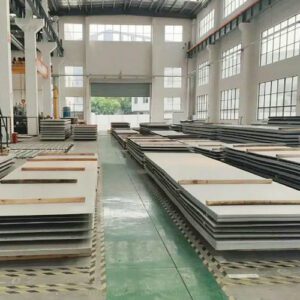

Stainless steel sheet suppliers offer a wide range of options for 430 stainless steel sheets, catering to different customer requirements. They provide flexibility in terms of dimensions, finishes, and quantities. Additionally, they may offer customized cutting and shaping services to meet specific project needs. It is advisable to work closely with reputable suppliers who can ensure the quality, consistency, and traceability of their products.

Conclusion: When considering 430 stainless steel sheets, it is important to have a clear understanding of the available specifications and dimensions. This knowledge allows for informed decision-making and ensures that the chosen product meets the requirements of the intended application. By collaborating with reliable stainless steel sheet suppliers, customers can access a diverse range of options and receive guidance in selecting the most suitable 430 stainless steel sheet for their projects.

In this article, we will explore how the composition of 430 stainless steel sheet affects its performance. Understanding the impact of different elements in the composition is crucial for assessing the material’s properties and determining its suitability for various applications. By examining the composition of 430 stainless steel sheet and its effects on performance, we can gain valuable insights into the material’s strength, corrosion resistance, and other key characteristics.

Chromium (Cr): 430 stainless steel contains a significant amount of chromium, typically ranging from 16 to 18 percent. Chromium enhances the material’s corrosion resistance, forming a passive oxide layer on the surface that protects against rust and oxidation.

Nickel (Ni): 430 stainless steel has a low nickel content, usually around 0.75 percent or less. The reduced nickel content contributes to the material’s lower cost compared to other stainless steel grades.

Carbon (C): The carbon content in 430 stainless steel is generally low, typically around 0.12 percent or less. The low carbon content helps to prevent sensitization and maintain good weldability.

Manganese (Mn): 430 stainless steel contains a small amount of manganese, usually around 1 percent or less. Manganese helps improve the material’s strength and hardness.

Silicon (Si): Silicon is present in small quantities in 430 stainless steel, typically around 1 percent or less. Silicon aids in improving the material’s resistance to scaling at high temperatures.

Other Trace Elements: 430 stainless steel may contain trace amounts of other elements, such as sulfur and phosphorus, which are controlled at low levels to ensure good material quality.

Corrosion Resistance: The chromium content in 430 stainless steel provides moderate corrosion resistance in non-aggressive environments, making it suitable for applications where exposure to moisture or mildly corrosive substances is expected.

Strength and Hardness: The combination of chromium and manganese contributes to the material’s strength and hardness, allowing it to withstand mechanical stress and deformation.

Weldability: The low carbon content in 430 stainless steel promotes good weldability, enabling the material to be easily joined through various welding processes.

Heat Resistance: 430 stainless steel exhibits moderate heat resistance, making it suitable for applications where exposure to elevated temperatures is intermittent or moderate.

Magnetic Properties: 430 stainless steel is a ferritic stainless steel grade, which means it is magnetic. This magnetic property can be advantageous in certain applications that require magnetic attraction or detection.

Conclusion: The composition of 430 stainless steel sheet, with its significant chromium content and low nickel and carbon content, plays a crucial role in determining its performance characteristics. The presence of chromium enhances corrosion resistance, while elements like manganese contribute to strength and hardness. Understanding the composition-performance relationship of 430 stainless steel sheet helps in selecting the appropriate material for specific applications. By collaborating with reliable stainless steel sheet suppliers, customers can access high-quality 430 stainless steel sheets that meet their performance requirements.

In this article, we will explore the specific applications where 430 stainless steel sheet is commonly used. Understanding the diverse range of industries and sectors that rely on this material will provide insights into its versatility and suitability for various environments. By examining these applications, we can highlight the key properties and benefits of 430 stainless steel sheet, as well as the importance of working with reputable stainless steel sheet suppliers to meet specific application requirements.

430 stainless steel sheet is widely used in the manufacturing of kitchen appliances, including refrigerators, ovens, dishwashers, and range hoods. Its corrosion resistance, durability, and ease of cleaning make it a preferred choice for these applications.

The automotive industry utilizes 430 stainless steel sheet for trim components, such as bumpers, grilles, and decorative accents. Its aesthetic appeal, corrosion resistance, and cost-effectiveness make it a popular choice.

430 stainless steel sheet finds applications in architectural projects, including wall cladding, roofing, and decorative elements. Its versatility in terms of finishes, patterns, and textures allows for creative designs in both indoor and outdoor settings.

Due to its excellent corrosion resistance and hygienic properties, 430 stainless steel sheet is commonly used in the manufacturing of catering equipment, such as food preparation surfaces, countertops, sinks, and serving trays.

Various industries, including chemical processing, oil and gas, and food processing, utilize 430 stainless steel sheet for equipment exposed to corrosive environments, such as tanks, containers, and machinery components.

430 stainless steel sheet is found in commercial kitchens and food service establishments for worktables, shelving, and storage units. Its durability, resistance to staining, and ease of maintenance make it suitable for demanding environments.

Some medical equipment, such as surgical trays, instrument panels, and dental tools, are made from 430 stainless steel sheet due to its corrosion resistance and compatibility with sterilization processes.

430 stainless steel sheet is used in heat exchangers for various industrial applications, including HVAC systems, chemical processing, and power plants. Its thermal conductivity and corrosion resistance make it a reliable choice.

430 stainless steel sheet is utilized in home improvement projects for applications such as backsplashes, countertops, and decorative accents. Its affordability, durability, and low maintenance requirements appeal to homeowners.

Other consumer goods, such as furniture, appliances, and electronic enclosures, may incorporate 430 stainless steel sheet for its aesthetic appeal, corrosion resistance, and versatility.

Conclusion: The applications of 430 stainless steel sheet span across a wide range of industries and sectors, including kitchen appliances, automotive, architecture, catering, industrial equipment, medical, heat exchangers, home improvement, and consumer goods. Its corrosion resistance, durability, aesthetic appeal, and cost-effectiveness make it a popular choice for numerous applications. Collaborating with reputable stainless steel sheet suppliers ensures access to high-quality 430 stainless steel sheets that meet the specific requirements of these applications.

In this article, we will compare and contrast two popular stainless steel grades, 304 and 430, to understand their similarities, differences, and applications. By examining their properties, composition, and performance, we can provide insights into which grade is more suitable for specific applications. Additionally, we will emphasize the importance of working with reliable stainless steel sheet suppliers to ensure the quality and consistency of the materials.

When choosing stainless steel sheet suppliers, several factors should be considered:

Conclusion: Understanding the differences between 304 and 430 stainless steel allows for informed decision-making when selecting the appropriate grade for specific applications. While 304 stainless steel offers superior corrosion resistance and formability, 430 stainless steel excels in strength, hardness, and cost-effectiveness. Collaborating with reputable stainless steel sheet suppliers is crucial to ensure the availability of high-quality materials and technical support. By considering the properties and applications of both grades, businesses can make well-informed choices that meet their specific requirements.

Selecting the appropriate supplier for SUS304 stainless steel sheets is crucial to ensure quality and reliability. This article provides a comprehensive guide on how to make an informed decision when choosing stainless steel sheet suppliers, focusing on the key considerations and factors that guarantee a successful procurement process.

Explore the essential properties of SUS304 stainless steel, such as its corrosion resistance, high-temperature resistance, and mechanical strength. Learn how these properties make it suitable for various applications.

Define your project requirements, including sheet dimensions, thickness, surface finish, and any additional specifications. This will help narrow down the list of potential suppliers that can meet your specific needs.

Evaluate the supplier’s expertise and experience in providing SUS304 stainless steel sheets. Consider factors such as their industry reputation, certifications, and track record in delivering high-quality products.

Ensure that the supplier follows stringent quality control measures and holds relevant certifications, such as ISO 9001, to guarantee the authenticity and quality of their SUS304 stainless steel sheets.

Verify the supplier’s ability to provide material traceability and comprehensive documentation, including mill test reports, chemical composition analysis, and mechanical property data. This ensures transparency and facilitates compliance with regulatory requirements.

Assess the supplier’s production capacity to meet your quantity demands. Additionally, consider their ability to provide on-time delivery, minimizing project delays and disruptions.

Compare prices among different suppliers while considering the overall value offered. Look for suppliers that provide competitive pricing without compromising on the quality of the SUS304 stainless steel sheets.

Evaluate the supplier’s commitment to customer satisfaction, including their responsiveness, technical support, and after-sales service. A reliable supplier should provide assistance throughout the procurement process and address any concerns promptly.

Consider the supplier’s environmental policies and practices, ensuring their adherence to sustainable manufacturing processes and responsible sourcing of raw materials.

Seek references and reviews from other customers to gauge the supplier’s reputation and customer satisfaction level. Positive feedback and recommendations indicate a reliable and trustworthy supplier.

Conclusion: Choosing the right SUS304 stainless steel sheet supplier involves careful evaluation of their expertise, quality assurance measures, delivery capabilities, pricing competitiveness, and customer support. By following these guidelines, you can make an informed decision and secure a reliable supplier for your SUS304 stainless steel sheet requirements.

430 stainless steel sheets are versatile materials that offer good corrosion resistance, moderate strength, and excellent thermal conductivity. They find applications in various industries and are cost-effective compared to other stainless steel grades. When choosing a supplier, consider their expertise, product range, quality assurance, customization options, and customer support. By selecting a reliable supplier, you can ensure the availability of high-quality 430 stainless steel sheets that meet your specific requirements.

Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours