With their exceptional strength and remarkable resistance, 440C stainless steel plates are the epitome of durability and reliability. Renowned for their superior performance in demanding environments, these plates have become the go-to choice for industries that demand nothing but the best. Whether it’s tackling extreme temperatures or withstanding harsh chemicals, 440C stainless steel plates rise to the challenge, ensuring longevity and peace of mind. Join us as we delve into the world of 440C stainless steel plates and uncover their incredible capabilities.

Property Value

Density :7.75 g/cm³

Melting Point: 1480 – 1530°C

Hardness (Rockwell C) :58 – 62 HRC

Tensile Strength: 760 – 2050 MPa

Elongation :10 – 14%

Chromium (Cr): 16% to 18%

Manganese (Mn): Up to 1%

Silicon (Si): Up to 1%

Carbon (C): Up to 0.12%

Phosphorus (P): Up to 0.04%

Sulfur (S): Up to 0.03%

Iron (Fe): Remaining balance

Element Composition (%)

Carbon (C) :0.95 – 1.20

Chromium (Cr): 16.00 – 18.00

Manganese (Mn): 1.00

Silicon (Si) :1.00

Phosphorus (P):0.04

Sulfur (S):0.03

440C stainless steel is a high-carbon martensitic stainless steel known for its excellent hardness, wear resistance, and corrosion resistance. This article aims to provide a comprehensive understanding of the properties of 440C stainless steel, including its composition, mechanical properties, heat treatment, and applications.So,is 440c stainless steel good?Let us see:

440C stainless steel is primarily composed of carbon, chromium, manganese, silicon, phosphorus, and sulfur. It has a carbon content of 0.95-1.20%, which contributes to its high hardness and wear resistance. The chromium content of 16.00-18.00% ensures its excellent corrosion resistance.

440C stainless steel can be hardened through heat treatment processes such as quenching and tempering. The specific heat treatment parameters influence the material’s hardness, toughness, and dimensional stability, allowing for tailored properties to meet different application requirements.

440C stainless steel demonstrates excellent corrosion resistance, particularly in mild environments. Its high chromium content forms a protective oxide layer, preventing corrosion and enhancing its durability.

440C stainless steel is widely used in various industries, including:

Conclusion: 440C stainless steel exhibits remarkable properties, including high hardness, excellent wear resistance, and good corrosion resistance. These properties make it a sought-after material for applications that demand strength, durability, and resistance to wear and corrosion. When sourcing 440C stainless steel, it is essential to partner with reputable stainless steel suppliers who can provide high-quality products to ensure optimal performance in various industries.

440C stainless steel is a high-carbon martensitic stainless steel known for its exceptional properties. This article aims to provide a comprehensive understanding of how the composition of 440C stainless steel contributes to its properties, including its hardness, wear resistance, and corrosion resistance.

440C stainless steel contains a high carbon content ranging from 0.95% to 1.20%. The significant carbon presence contributes to the material’s high hardness and wear resistance. It enables 440C stainless steel to achieve excellent edge retention and make it suitable for applications requiring superior cutting performance.

The chromium content in 440C stainless steel ranges from 16.00% to 18.00%. Chromium plays a crucial role in enhancing the material’s corrosion resistance. It forms a protective oxide layer on the surface, preventing oxidation and corrosion even in harsh environments.

The addition of manganese and silicon in controlled amounts improves the hardenability and strength of 440C stainless steel. These elements promote the formation of a fine and uniform martensitic structure during heat treatment, leading to increased hardness and strength.

Phosphorus and sulfur are impurity elements typically present in low amounts in 440C stainless steel. While they can negatively impact the material’s ductility and toughness, careful control of their levels ensures the desired mechanical properties are maintained.

Conclusion: The composition of 440C stainless steel, characterized by its high carbon and chromium content, plays a vital role in determining its remarkable properties. The significant carbon content contributes to its hardness and wear resistance, while chromium enhances its corrosion resistance. The controlled addition of other alloying elements further improves its mechanical properties. Understanding the impact of composition on the properties of 440C stainless steel is essential when selecting materials for applications that require high hardness, wear resistance, and corrosion resistance. Working with reputable 440C stainless steel suppliers ensures the availability of high-quality materials that meet specific requirements in various industries.

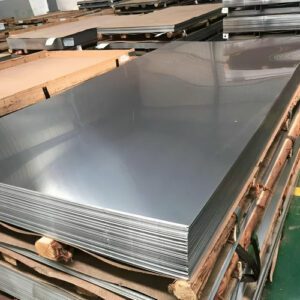

440C stainless steel plates are widely used in various industries due to their exceptional properties. This article aims to provide comprehensive information on the available dimensions and thicknesses for 440C stainless steel plates. Understanding these specifications is crucial for selecting the right material for specific applications.

440C stainless steel plates are available in standard dimensions that conform to industry standards. The most common standard sizes include:

In addition to standard sizes, reputable 440C stainless steel suppliers offer the flexibility of custom dimensions. This allows customers to specify their desired plate sizes according to their unique project requirements. Custom dimensions can include variations in thickness, width, and length, catering to specific needs.

440C stainless steel plates are available in a range of thicknesses to accommodate different applications. Common thicknesses include:

440C stainless steel plate suppliers ensure the highest quality by offering plates with precise tolerances. These tolerances guarantee the accuracy and consistency of the plate dimensions, ensuring they meet the required specifications.

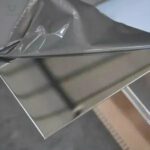

440C stainless steel plates are available in various surface finishes to meet specific application needs. Common finishes include mill finish, brushed finish, and mirror finish. The choice of surface finish depends on factors such as aesthetics, corrosion resistance, and ease of cleaning.

Conclusion: 440C stainless steel plates are available in a range of dimensions and thicknesses, providing flexibility for various industrial applications. Standard sizes and custom dimensions allow customers to select plates that meet their specific project requirements. The availability of different thicknesses caters to a wide range of applications, from thin plates for precision components to thick plates for heavy-duty applications. Reputable 440C stainless steel suppliers ensure precision tolerances and offer various surface finishes to meet customer needs. Understanding the available dimensions and thicknesses is essential when procuring 440C stainless steel plates for projects that require high strength, hardness, and corrosion resistance.

440C stainless steel plates offer exceptional properties that make them suitable for various applications across different industries. This article aims to explore the specific applications where 440C stainless steel plates are commonly used. Understanding these applications can help industries make informed decisions when choosing 440C stainless steel as their material of choice.

440C stainless steel plates are widely utilized in tool and die making due to their high hardness and wear resistance. They are commonly used for manufacturing cutting tools, knives, blades, and punches that require excellent edge retention and durability.

440C stainless steel plates find extensive use in the production of bearings and ball valves. The material’s high corrosion resistance, combined with its ability to withstand high loads and temperatures, makes it suitable for demanding applications in the automotive, aerospace, and marine industries.

440C stainless steel plates are favored in the medical field for manufacturing surgical instruments. The material’s exceptional corrosion resistance, high hardness, and biocompatibility make it ideal for applications requiring sterilization, such as scalpels, forceps, and surgical blades.

The high wear resistance and hardness of 440C stainless steel plates make them suitable for molding and die applications. They are commonly used in injection molding, extrusion dies, and forming dies, where resistance to wear, heat, and corrosion is crucial for prolonged tool life and productivity.

440C stainless steel plates are utilized in industrial applications that involve cutting, slicing, and shearing processes. Their high hardness, excellent edge retention, and corrosion resistance make them ideal for manufacturing industrial knives, cutters, shears, and slitters.

440C stainless steel plates find applications in the aerospace industry for producing components that require high strength, corrosion resistance, and wear resistance. These plates are used in the manufacturing of aircraft bearings, turbine parts, and critical aerospace components.

440C stainless steel plates are well-suited for petrochemical applications due to their resistance to corrosion, high temperatures, and aggressive chemicals. They are used in the construction of valves, pumps, fittings, and other equipment that operates in demanding petrochemical environments.

440C stainless steel plates are employed in the food processing industry for manufacturing equipment such as cutting blades, mincing knives, and meat processing machinery. The material’s corrosion resistance, hygienic properties, and ease of cleaning make it suitable for maintaining high sanitary standards.

Conclusion: 440C stainless steel plates are versatile and find applications in various industries due to their exceptional properties. From tool and die making to surgical instruments, bearings to industrial knives, and aerospace components to petrochemical equipment, 440C stainless steel plates offer high strength, corrosion resistance, and wear resistance. These plates meet the demanding requirements of industries that require durable, reliable, and high-performance materials. When considering applications that involve high hardness, excellent edge retention, and resistance to corrosion and wear, 440C stainless steel plates are a preferred choice.

440C stainless steel plates are highly regarded in various industries for their exceptional properties and performance. This article aims to explore the factors that make 440C stainless steel plates a preferred choice in certain industries. Understanding these advantages can assist industries in making informed decisions when selecting materials for their specific applications.

440C stainless steel plates exhibit remarkable hardness and wear resistance, making them ideal for industries such as tool and die making, industrial knives, and mold and die applications. The material can withstand heavy use, resist deformation, and maintain excellent edge retention, ensuring prolonged tool life and enhanced productivity.

440C stainless steel plates offer excellent corrosion resistance, particularly in environments where exposure to moisture, chemicals, or high temperatures is a concern. Industries such as petrochemical, food processing, and aerospace rely on the material’s corrosion resistance to maintain performance and integrity in demanding operating conditions.

The exceptional edge retention of 440C stainless steel plates makes them highly sought after in industries requiring sharp cutting tools, surgical instruments, and precision components. The material’s ability to maintain a sharp edge over prolonged use ensures precision, accuracy, and efficiency in critical applications.

440C stainless steel plates possess high strength and durability, making them suitable for applications subjected to heavy loads, impacts, and harsh environments. Industries such as aerospace, automotive, and marine benefit from the material’s ability to withstand extreme conditions while maintaining structural integrity.

In the medical field, 440C stainless steel plates are preferred for surgical instruments and implants due to their biocompatibility. The material’s non-toxic nature, resistance to body fluids, and compatibility with sterilization processes make it a reliable choice for safe and effective medical procedures.

440C stainless steel plates offer versatility in terms of fabrication and machining, allowing them to be customized for specific industry requirements. Their adaptability enables them to be used in various applications, including bearings, ball valves, and food processing machinery, where different shapes, sizes, and functionalities are needed.

Conclusion: 440C stainless steel plates possess a unique combination of properties that make them highly favored in specific industries. Their high hardness, wear resistance, corrosion resistance, superior edge retention, and biocompatibility contribute to their suitability in tool and die making, surgical instruments, aerospace, petrochemical, and other critical applications. The material’s strength, durability, versatility, and adaptability further enhance its appeal in various industries. When seeking materials that offer exceptional performance, longevity, and reliability, 440C stainless steel plates emerge as a preferred choice, ensuring optimal outcomes in demanding industrial environments.

When it comes to procuring 440C stainless steel plates, selecting a reliable supplier is crucial to ensure the quality, availability, and timely delivery of the desired products. This article aims to outline the key factors to consider when choosing a supplier for 440C stainless steel plates. By understanding these factors, industries can make informed decisions and establish successful partnerships with reputable suppliers.

Ensure that the supplier has a robust quality assurance system in place. Look for certifications such as ISO 9001, which demonstrate their commitment to maintaining stringent quality standards. Verify if the supplier conducts regular inspections, tests, and certifications to guarantee the authenticity and quality of the 440C stainless steel plates.

A reliable supplier should offer a wide range of 440C stainless steel plate options, including different sizes, thicknesses, and finishes. They should have a comprehensive inventory to meet various industry requirements promptly. Additionally, inquire about their sourcing capabilities to ensure a stable supply of high-quality materials.

Evaluate the supplier’s technical expertise in handling 440C stainless steel plates. A knowledgeable supplier can provide guidance on material selection, application suitability, and offer recommendations based on specific industry needs. Their expertise ensures that you receive the right products for your intended applications.

Assess the supplier’s manufacturing capabilities and facilities. Ideally, they should have advanced equipment and processes to ensure precision cutting, machining, and fabrication of 440C stainless steel plates. This capability ensures the delivery of accurately dimensioned and finished products.

Consider the supplier’s track record in terms of delivery reliability and logistics efficiency. On-time delivery is critical to avoid project delays and maintain smooth operations. Inquire about their shipping and packaging methods to ensure the safe and secure transportation of the stainless steel plates to your location.

Choose a supplier that values customer satisfaction and provides excellent support. They should be responsive to inquiries, provide clear communication, and address any concerns promptly. A reliable supplier will establish a long-term partnership by offering reliable after-sales support and addressing any issues that may arise.

While price should not be the sole determining factor, it is important to consider the supplier’s pricing competitiveness. Compare prices from multiple suppliers to ensure that you are receiving fair pricing for the 440C stainless steel plates without compromising on quality.

Research the supplier’s reputation within the industry. Look for reviews, testimonials, and references from other customers to gain insight into their reliability, professionalism, and overall performance. A supplier with a positive reputation and satisfied customers is more likely to meet your expectations.

Research the supplier’s reputation within the industry. Look for reviews, testimonials, and references from other customers to gain insight into their reliability, professionalism, and overall performance. A supplier with a positive reputation and satisfied customers is more likely to meet your expectations.

What are the specifications of 440C stainless steel plates? Answer: The specifications of 440C stainless steel plates include different dimensions, thicknesses, and surface finishes. Suppliers typically offer various options to meet the requirements of different industries.

What is the composition of 440C stainless steel plates? Answer: The composition of 440C stainless steel plates includes approximately 1.0% carbon, 17-18% chromium, around 1.0% molybdenum, and approximately 1.0% manganese. These specific chemical compositions give 440C stainless steel plates excellent wear resistance and corrosion resistance.

What are the properties of 440C stainless steel plates? Answer: 440C stainless steel plates exhibit excellent hardness, wear resistance, and corrosion resistance. They also have good machinability and resistance to deformation, making them suitable for high-load and high-temperature environments.

Is 440C stainless steel plates a high-quality material? Answer: Yes, 440C stainless steel plates are widely recognized as a high-quality material. Their outstanding hardness, wear resistance, and corrosion resistance make them a preferred choice in various industries.

What factors should be considered when selecting a reliable supplier for 440C stainless steel plates? Answer: When choosing a reliable supplier for 440C stainless steel plates, several factors should be considered. These factors include quality assurance, material selection and availability, technical expertise, manufacturing capabilities, delivery and logistics, customer support, competitive pricing, as well as reputation and references.

In conclusion: 440C stainless steel plates possess excellent hardness, wear resistance, and corrosion resistance, making them an ideal choice in many industries. Selecting a reliable supplier is crucial to obtain high-quality 440C stainless steel plates. By considering factors such as quality assurance, material selection and availability, technical expertise, manufacturing capabilities, delivery and logistics, customer support, competitive pricing, as well as reputation and references, industries can ensure a stable supply of high-quality 440C stainless steel plates to meet project requirements and achieve long-term success.

Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours