Stainless steel is renowned for its incredible durability, corrosion resistance, and aesthetic appeal. One common application you might have come across is the mirror finish stainless steel, an ultra-smooth and highly reflective surface that lends a sophisticated, modern edge to architectural and design projects. In this post, we’ll delve into the fascinating process behind achieving that mirror-like shine on stainless steel. As a leading stainless steel plate supplier, we take great pride in the quality of our products and believe in sharing the science and craft behind their creation.

So,How to polish stainless steel to a mirror finish?

Clean the surface, sand out imperfections, apply polishing compound, buff in circular motions, and clean off residue.

While the problem may seem simple, in reality, it involves many complicated factors and technical details. In the following articles, we will delve deeper into these issues and answer these common but confusing questions for you.

Mirror finish stainless steel is stainless steel that has been polished to a mirror-like finish. It is often characterized by its high-gloss surface, which is achieved by using an intensive polishing process. The result? A beautifully reflective surface that’s not only a pleasure to look at but also supremely functional, thanks to stainless steel’s inherent properties.

The journey to achieving a mirror finish on stainless steel entails several meticulous steps, each contributing towards the final high-quality, shiny output.

The journey begins with the selection of high-grade stainless steel plates. As reliable stainless steel plate suppliers, we ensure the use of only the finest quality raw materials.

Next, the selected stainless steel plates are carefully cut into the required dimensions. Precision in this step lays the foundation for a flawless mirror finish stainless steel.

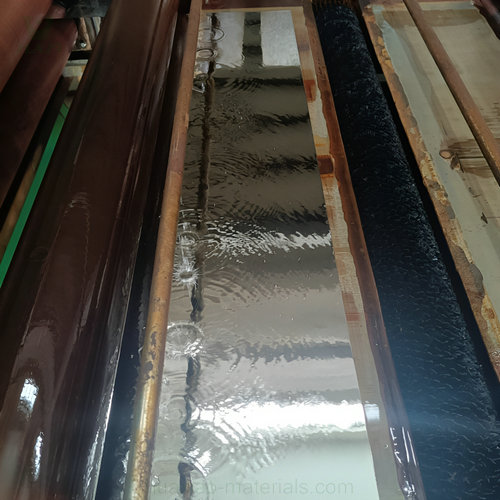

Thoroughly clean the stainless steel surface using a mild detergent and water to remove dirt, grease, and contaminants. Rinse and dry the surface completely.

Begin by using a coarse-grit abrasive wheel or belt to remove any surface imperfections, scratches, or weld marks. Ensure consistent pressure and follow the recommended grinding direction.

Progressively switch to finer grit abrasive wheels or belts to refine the surface and eliminate visible grinding marks. Maintain a steady and controlled grinding motion.

Apply a high-quality stainless steel polishing compound onto a soft cloth or a buffing wheel. Work in small sections, using light pressure and consistent circular motions.

Continue polishing the surface with the compound, gradually reducing the pressure and adjusting the speed. Ensure even coverage and regularly inspect the progress.

Switch to a fine polishing compound and carefully buff the surface until the desired mirror-like shine is achieved. Use clean polishing pads or cloths for each compound.

Thoroughly clean the polished surface with a mild cleaner to remove any residue or compound. Inspect the entire surface under proper lighting to ensure a flawless mirror finish stainless steel.

Always adhere to safety guidelines, wear protective gear, and work in a well-ventilated area when polishing stainless steel. Consult reputable stainless steel plate suppliers for specific recommendations and high-quality products to achieve exceptional mirror finishes.

As a trusted stainless steel supplier, our company offers extensive expertise, premium stainless steel products, and comprehensive support to meet your mirror finish stainless steel requirements.

A mirror finish stainless steel greatly enhances the aesthetic appeal of stainless steel products through its exceptional visual qualities. Here’s how it elevates the overall look:

The mirror finish on stainless steel creates a highly reflective surface that effectively captures and reflects light. This reflective property adds depth and dimension to the material, making it visually striking and captivating.

The smooth and flawless surface of a mirror finish stainless steelimparts a sleek and contemporary look to stainless steel products. It exudes a sense of sophistication and elegance, making them stand out in various applications.

The mirror-like surface ensures distortion-free reflections, allowing stainless steel to mirror its surroundings accurately. This quality enhances the visual appeal and creates a sense of harmony when incorporated into architectural or design elements.

The mirror finish stainless steel gives stainless steel a luxurious and expensive feel, making it a preferred choice in high-end applications. It adds a touch of prestige and exclusivity to products, elevating their perceived value.

The mirror finish stainless steel seamlessly complements various design styles and materials. It can be incorporated into both modern and traditional settings, enhancing the overall aesthetic cohesiveness of the space.

As a reputable stainless steel plate supplier, our company understands the importance of achieving a flawless mirror finish stainless steel. With our scientific expertise and premium-quality stainless steel, we can help you create visually stunning products that leave a lasting impression. Contact us to explore our range of mirror polished stainless steel and elevate your designs to new heights.

To achieve a mirror finish on stainless steel, it is crucial to use the right polishing compounds. Here are some recommended compounds known for their effectiveness:

Start with a coarse abrasive compound, such as emery or tripoli, to remove any scratches, imperfections, or oxidation from the stainless steel surface.

Next, use a series of finer polishing compounds, such as white rouge or jewelers rouge, to progressively refine the surface and enhance its shine. These compounds contain fine abrasive particles suspended in a wax or grease base.

Finally, apply a high-quality finishing compound, such as a jeweler’s rouge or a chrome oxide compound, to further refine and bring out the mirror-like shine of the stainless steel surface.

It is important to note that the specific polishing compounds and their application techniques may vary depending on the type and condition of the stainless steel. Consult with a professional or refer to manufacturer guidelines for precise recommendations.

As a trusted stainless steel plate supplier, our company can provide you with the expertise and guidance you need to achieve the desired mirror finish stainless steel. Contact us for information on our range of mirror polished stainless steel products and recommended polishing techniques.

Polishing stainless steel to a mirror finish stainless steel can present certain challenges. Here are some common ones:

Stainless steel surfaces are prone to scratches and blemishes, which can hinder the achievement of a mirror finish stainless steel. It requires careful preparation and polishing techniques to remove these imperfections effectively.

Contaminants such as oils, dirt, and fingerprints can mar the mirror finish. Thorough cleaning and maintaining a clean working environment are essential to prevent surface contamination during the polishing process.

Achieving a uniform mirror finish stainless steel across the entire stainless steel surface can be challenging. It requires consistent pressure, proper polishing tools, and techniques to ensure even and consistent results.

Excessive heat generated during the polishing process can lead to discoloration or warping of the stainless steel. Careful control of speed, pressure, and cooling techniques is necessary to prevent heat-related issues.

Some grades of stainless steel can be harder to polish than others due to their composition and metallurgical properties. Adjusting the polishing techniques and using appropriate abrasives and compounds is important to address these challenges.

As a reputable stainless steel supplier, our company understands these challenges and can provide you with the expertise, high-quality materials, and guidance to overcome them. Contact us for more information on our mirror finish stainless steel products and recommendations for achieving excellent results.

To achieve a mirror finish on stainless steel, certain polishing compounds are recommended. Here are some commonly used ones:

These compounds contain abrasive particles that help remove scratches and imperfections from the stainless steel surface. Diamond paste or aluminum oxide compounds are commonly used for initial polishing stages.

Once the surface is prepared, finishing compounds are applied to further refine and enhance the mirror finish stainless steel. Compounds like rouge or cerium oxide are popular choices for final polishing stages.

The choice of polishing wheels or pads depends on the specific requirements and the size and shape of the stainless steel surface. Cotton buffs, felt wheels, or foam pads are commonly used with polishing compounds for effective results.

Using lubricants or coolants during the polishing process can help reduce friction, prevent overheating, and improve the overall polishing performance. Water, mineral oil, or specialized polishing lubricants can be used.

The application technique also plays a crucial role in achieving a mirror finish stainless steel. Using slow and controlled movements, applying consistent pressure, and ensuring even coverage are key aspects to consider.

Conclusion: Both stainless steel welded pipes and seamless pipes have their unique advantages and considerations in terms of performance. Welded pipes offer good strength, cost-effectiveness, and customization options, while seamless pipes provide superior corrosion resistance, uniform strength, and a seamless appearance. The choice between the two depends on factors such as the application requirements, budget, size, and aesthetics. Consulting with reputable stainless steel pipe suppliers and considering specific project needs will help determine the most suitable option for achieving optimal performance.

When it comes to polishing stainless steel to a mirror finish, several buffing techniques and tools can be used. Here are some commonly employed methods:

Hand buffing involves using soft cloths or microfiber towels along with polishing compounds to manually rub and polish the stainless steel surface. This technique is suitable for smaller areas or intricate designs.

Rotary buffing utilizes a rotary tool or polishing machine equipped with buffing wheels. Various types of buffing wheels, such as cotton, sisal, or felt wheels, can be used along with appropriate polishing compounds to achieve the desired mirror finish stainless steel.

Orbital buffing machines are another option for polishing stainless steel. These machines oscillate in a circular motion, allowing for even and controlled buffing. They are often used with foam pads or bonnets and can deliver consistent results.

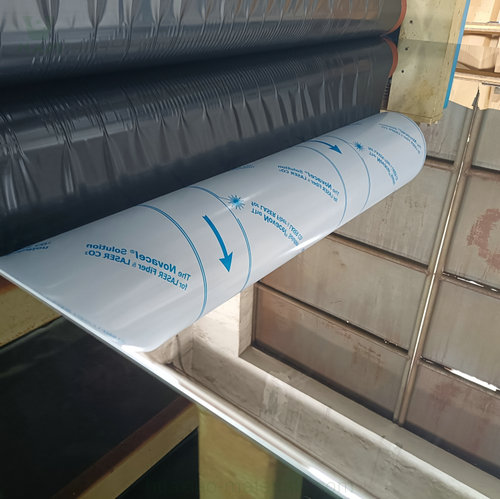

Belt buffing is commonly used for larger stainless steel surfaces or flat sheet materials. It involves passing the stainless steel through a series of abrasive belts or wheels to remove imperfections and achieve a smooth, mirror-like finish.

In industrial settings, automatic polishing systems are employed for high-volume production. These systems utilize specialized machinery with multiple buffing heads and automated processes to efficiently polish stainless steel surfaces.

When selecting buffing tools, consider factors such as the surface area, shape, and complexity of the stainless steel component. Additionally, choose the appropriate polishing compounds and lubricants to enhance the buffing process and achieve optimal results.

As a trusted stainless steel supplier, our company can provide guidance on the best buffing techniques and tools for your specific needs. Contact us for further information and to discuss your requirements.

To achieve a uniform and consistent mirror finish stainless steel across the entire stainless steel surface, several factors should be considered:

Ensure that the stainless steel surface is properly cleaned and free from contaminants, such as oils, dirt, or rust. Use appropriate cleaning agents and techniques to ensure a pristine starting point for polishing.

Employ consistent and controlled buffing techniques, such as using even pressure, maintaining steady movements, and overlapping strokes. This helps distribute the polishing compounds and achieve a uniform finish.

Choose high-quality polishing compounds that are specifically designed for stainless steel. These compounds should provide a consistent cutting action and deliver uniform results across the surface.

Select buffing wheels or pads that are suitable for the size and shape of the stainless steel surface. Ensure that they are in good condition and regularly clean or replace them to avoid any uneven or inconsistent polishing.

Maintain a consistent speed and RPM (rotations per minute) during the polishing process. This helps prevent variations in the polishing action and promotes uniformity across the surface.

Adequate lighting is crucial to identify any areas that require additional attention or may exhibit unevenness. Regularly inspect the surface during the polishing process to address any inconsistencies promptly.

Conduct periodic testing by examining small sections of the surface to ensure uniformity. Adjust the polishing technique or compounds as needed to achieve a consistent mirror finish stainless steel.

By following these guidelines and utilizing the expertise of a reputable stainless steel supplier like our company, you can ensure a uniform and consistent mirror finish stainless steel across the entire stainless steel surface. Contact us for further assistance and to discuss your specific requirements.

In this blog post, we explored the significance of achieving a mirror finish on stainless steel surfaces. We discussed the aesthetic appeal it brings to stainless steel products and how it enhances their overall visual impact. We also examined the essential steps involved in preparing the surface for polishing, including cleaning, smoothing, and removing imperfections.

Furthermore, we delved into the recommended polishing compounds for achieving a mirror finish stainless steel. Different compounds with varying abrasive properties were highlighted, allowing users to select the most suitable one for their specific polishing needs.

We also explored the common challenges encountered when polishing stainless steel to a mirror finish. These challenges included scratches, uneven surfaces, and difficulty in removing deep stains. We provided insights into addressing these challenges through proper techniques, tools, and the use of high-quality polishing compounds.

Additionally, we discussed the various buffing techniques and tools that can be utilized for stainless steel polishing. From handheld tools to machine buffing, different methods were presented to cater to diverse project requirements.

Finally, we emphasized the importance of achieving a uniform and consistent mirror finish across the entire stainless steel surface. Factors such as surface preparation, buffing technique, polishing compounds, and regular inspection were highlighted as key elements in ensuring a flawless and even finish.

By following the guidelines presented in this blog post, readers can achieve remarkable mirror finishes on stainless steel surfaces. For further assistance and to explore our range of stainless steel products, feel free to contact our company, a trusted stainless steel supplier.

Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours