Welcome to our comprehensive guide on stainless steel seamless pipes. As a leading supplier in the industry, we understand the importance of selecting the right type of stainless steel pipe for your specific needs. In this article, we will delve into the features, benefits, and applications of stainless steel seamless pipes. Whether you’re involved in construction, manufacturing, or any other industry requiring reliable piping solutions, this guide will provide you with valuable insights to make informed decisions. Let’s explore the world of stainless steel seamless pipes and discover how they can enhance your projects.

So,what is cold rolled stainless steel seamless pipe?

Cold-rolled seamless stainless steel pipes, available in various common grades such as 304, 316, and 321, are produced using a cold-rolling process. These pipes offer exceptional corrosion resistance, strength, and dimensional accuracy. They are widely used in industries like construction, petrochemical, and food processing for their superior performance and versatility.

From understanding the definition and differences compared to other types of stainless steel pipes, to exploring the available sizes, dimensions, and specifications, we will cover all the essential aspects. We will also delve into the key properties and characteristics that make cold-rolled stainless steel seamless pipes a preferred choice in various industries.

Furthermore, we’ll discuss the cost-effectiveness and longevity of these pipes, helping you understand the long-term value they offer. Lastly, we’ll guide you on how to find reputable suppliers who can meet your specific requirements for cold-rolled stainless steel seamless pipes.

Whether you’re a construction professional, manufacturer, or involved in any industry that demands reliable piping solutions, this guide is designed to provide you with the information you need. So, let’s embark on this journey together and discover the benefits and applications of cold-rolled stainless steel seamless pipes.

Welcome to our comprehensive guide on stainless steel seamless pipes. In this article, we will explore the world of stainless steel seamless pipes, specifically focusing on cold-rolled stainless steel seamless pipes. We’ll provide valuable insights to help you understand the unique features and benefits of stainless steel seamless pipes for your projects.

A cold-rolled stainless steel seamless pipe is a cylindrical tube produced through a cold rolling technique. It is made from high-quality stainless steel, ensuring exceptional strength, corrosion resistance, and durability. Cold rolling involves passing the stainless steel strip or coil through a set of rollers at room temperature, resulting in a seamless pipe without welding or seams.

Compared to other types of stainless steel pipes, such as welded or hot-rolled pipes, cold-rolled stainless steel seamless pipes offer several distinct advantages. They exhibit superior dimensional accuracy, smooth surface finish, and enhanced mechanical properties. The absence of welds or seams eliminates the risk of weak points and potential corrosion sites, making them highly suitable for demanding applications.

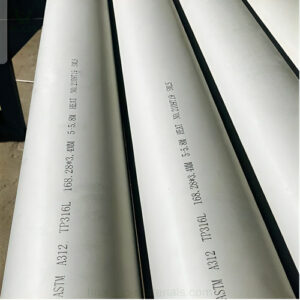

Stainless steel seamless pipes are available in a wide range of sizes, dimensions, and specifications to cater to diverse project requirements. Common sizes include those specified by industry standards, such as ASTM and ASME, as well as customized dimensions to meet specific applications. These pipes are available in various grades, such as 304, 316, and more, offering different levels of corrosion resistance and mechanical properties.

Cold-rolled stainless steel seamless pipes offer excellent corrosion resistance, ensuring longevity and reliability in challenging environments. They are highly resistant to chemical corrosion, oxidation, and high-temperature conditions. With their smooth and seamless surface, they minimize fluid friction, making them ideal for fluid transportation applications. Additionally, stainless steel seamless pipes provide exceptional strength, impact resistance, and low maintenance requirements.

While the initial cost of stainless steel seamless pipes may be higher than some alternatives, their long-term cost-effectiveness is undeniable. The durability and corrosion resistance of these pipes significantly reduce maintenance, repair, and replacement costs over time. Their longevity ensures a reliable and efficient piping system that withstands harsh conditions, minimizing downtime and associated expenses.

To obtain high-quality stainless steel seamless pipes, it is essential to source from reputable suppliers. Look for suppliers with a proven track record, certifications, and a wide range of stainless steel seamless pipe options. Conduct thorough research, read customer reviews, and seek recommendations to ensure you choose a supplier that can meet your specific needs and deliver reliable products.

Conclusion: Cold-rolled stainless steel seamless pipes offer exceptional performance, durability, and corrosion resistance for various applications. Their seamless construction, precise dimensions, and superior properties make them an excellent choice for critical projects. By understanding the characteristics and benefits of stainless steel seamless pipes, you can make informed decisions to meet your project requirements effectively.

In this informative article, we will explore the key distinctions between stainless steel seamless pipes and other types of stainless steel pipes. Understanding these differences is crucial for making informed decisions when selecting the most suitable piping solution for your specific needs.

Stainless steel seamless pipes are manufactured through a seamless process, which involves the absence of welds or seams. They are produced from a solid stainless steel billet or bar, which is heated and pierced to create a hollow cylindrical shape. This seamless construction ensures enhanced strength, reliability, and exceptional corrosion resistance.

In contrast, other types of stainless steel pipes, such as welded pipes, are manufactured by joining two or more pieces of stainless steel together using welding techniques. This welding process introduces weld seams along the length of the pipe, which may affect the overall integrity and corrosion resistance of the pipe.

Seamless Integrity: Stainless steel seamless pipes have a seamless structure without welds or seams, eliminating the risk of weak points and potential corrosion sites found in welded pipes.

Strength and Durability: The seamless construction of stainless steel seamless pipes provides superior strength and durability, making them ideal for demanding applications where structural integrity is crucial.

Seamless pipes offer exceptional corrosion resistance due to their seamless structure, which minimizes the chances of corrosive agents penetrating the pipe walls. This feature is particularly important in environments where corrosion is a concern.

The absence of weld seams in seamless pipes ensures a smooth inner surface, reducing friction and allowing for efficient fluid flow. This is advantageous in applications that involve fluid transportation.

Conclusion: Stainless steel seamless pipes differ from other types of stainless steel pipes in terms of their seamless integrity, enhanced strength and durability, superior corrosion resistance, and smooth inner surface. These distinctions make stainless steel seamless pipes a preferred choice for critical applications where reliability, longevity, and efficient fluid flow are paramount considerations. By understanding these differences, you can confidently select the most appropriate stainless steel piping solution for your specific requirements.

In this comprehensive article, we will delve into the various sizes, dimensions, and specifications of cold-rolled stainless steel seamless pipes. Understanding these aspects is essential for selecting the appropriate pipe that meets your specific project requirements.

| Size (Nominal Diameter) | Wall Thickness | Outer Diameter Tolerance | Length Tolerance | Material Grade | Standard |

|---|---|---|---|---|---|

| 1/8″ (3.175 mm) | 0.035″ (0.89 mm) | ±0.005″ (±0.13 mm) | +3/16″ (4.76 mm) | 304/304L, 316/316L | ASTM A312, ASTM A269 |

| 1/4″ (6.35 mm) | 0.049″ (1.24 mm) | ±0.005″ (±0.13 mm) | +3/16″ (4.76 mm) | 304/304L, 316/316L | ASTM A312, ASTM A269 |

| 3/8″ (9.525 mm) | 0.049″ (1.24 mm) | ±0.005″ (±0.13 mm) | +3/16″ (4.76 mm) | 304/304L, 316/316L | ASTM A312, ASTM A269 |

| 1/2″ (12.7 mm) | 0.065″ (1.65 mm) | ±0.005″ (±0.13 mm) | +3/16″ (4.76 mm) | 304/304L, 316/316L | ASTM A312, ASTM A269 |

| 3/4″ (19.05 mm) | 0.065″ (1.65 mm) | ±0.005″ (±0.13 mm) | +3/16″ (4.76 mm) | 304/304L, 316/316L | ASTM A312, ASTM A269 |

| 1″ (25.4 mm) | 0.065″ (1.65 mm) | ±0.008″ (±0.20 mm) | +3/16″ (4.76 mm) | 304/304L, 316/316L | ASTM A312, ASTM A269 |

| 1-1/4″ (31.75 mm) | 0.065″ (1.65 mm) | ±0.008″ (±0.20 mm) | +3/16″ (4.76 mm) | 304/304L, 316/316L | ASTM A312, ASTM A269 |

| 1-1/2″ (38.1 mm) | 0.065″ (1.65 mm) | ±0.008″ (±0.20 mm) | +3/16″ (4.76 mm) | 304/304L, 316/316L | ASTM A312, ASTM A269 |

| 2″ (50.8 mm) | 0.065″ (1.65 mm) | ±0.008″ (±0.20 mm) | +3/16″ (4.76 mm) | 304/304L, 316/316L | ASTM A312, ASTM A269 |

Cold-rolled stainless steel seamless pipes are available in a wide range of sizes and dimensions to accommodate diverse applications. Common sizes typically range from small diameters of 1/8 inch (3.175 mm) to larger diameters exceeding 20 inches (508 mm). The wall thickness of these pipes can vary, ranging from thin-walled pipes to heavy-duty pipes, depending on the intended use.

Stainless steel seamless pipes are manufactured in compliance with industry standards and specifications to ensure consistent quality and performance. Commonly used specifications include ASTM A312, ASTM A790, and ASTM A269, which outline the requirements for material composition, mechanical properties, dimensions, and tolerances.

Cold-rolled stainless steel seamless pipes are available in various material grades to suit different applications and environments. The most commonly used grades include 304 stainless steel and 316 stainless steel, renowned for their corrosion resistance, strength, and versatility.

In addition to standard sizes and specifications, manufacturers can also provide customized solutions to meet specific project requirements. These may include unique sizes, specialized dimensions, or additional surface finishes.

Conclusion: When considering cold-rolled stainless steel seamless pipes, it is important to understand the available sizes, dimensions, and specifications. These pipes come in a wide range of sizes to accommodate different applications, and they conform to industry standards such as ASTM A312, ASTM A790, and ASTM A269. Material grades such as 304 and 316 stainless steel are commonly used, offering excellent corrosion resistance and strength. By considering these factors, you can select the most suitable cold-rolled stainless steel seamless pipes for your project needs.

Stainless steel seamless pipes exhibit excellent corrosion resistance, making them suitable for various environments, including acidic, alkaline, and corrosive atmospheres.

Cold-rolled stainless steel seamless pipes have high tensile strength and can withstand high-pressure applications.

The seamless manufacturing process ensures a continuous and uniform structure, eliminating the risk of weak points or leakage.

These pipes are known for their durability and longevity, providing long-term reliability even in challenging conditions.

Cold-rolled stainless steel seamless pipes can withstand high temperatures without deformation or loss of mechanical properties.

The smooth surface of seamless pipes makes them resistant to bacterial growth and facilitates easy cleaning, making them ideal for sanitary applications.

Stainless steel seamless pipes are available in various grades, such as 304 and 316, offering versatility for different industry requirements.

These pipes can be easily welded, allowing for efficient installation and customization.

Cold-rolled stainless steel seamless pipes require minimal maintenance, reducing downtime and operating costs.

With their sleek and polished surface, stainless steel seamless pipes enhance the visual appeal of architectural and decorative applications.

Conclusion: Cold-rolled stainless steel seamless pipes possess these key properties and characteristics, making them a preferred choice for various industrial and commercial applications.

When evaluating the cost-effectiveness and longevity of cold-rolled stainless steel seamless pipes, several factors come into play:

While cold-rolled stainless steel seamless pipes may have a higher initial cost compared to other types of pipes, their superior durability and longevity can offset this initial investment over the long term.

Cold-rolled stainless steel seamless pipes require minimal maintenance and have excellent resistance to corrosion, reducing the need for frequent repairs and replacements. This leads to cost savings in terms of maintenance expenses and downtime.

These seamless pipes have a longer lifespan compared to other pipe materials. Their resistance to corrosion, wear, and degradation ensures prolonged service life, reducing the need for frequent replacements and associated costs.

Cold-rolled stainless steel seamless pipes offer smooth internal surfaces that minimize friction and pressure loss. This improves fluid flow efficiency and can result in energy savings over time.

Stainless steel seamless pipes come in various grades, sizes, and specifications to suit different applications. Their adaptability reduces the risk of mismatched fittings and potential maintenance or replacement costs.

Cold-rolled stainless steel seamless pipes are environmentally friendly, as they are recyclable and contribute to sustainable practices. This aspect aligns with the growing focus on sustainability and can have long-term benefits for both the environment and regulatory compliance.

In conclusion, while cold-rolled stainless steel seamless pipes may have a higher upfront cost, their cost-effectiveness and longevity surpass other pipe types. Their durability, low maintenance requirements, extended lifespan, and operational efficiency make them a reliable and cost-efficient choice for various applications.

Note: Cold-rolled stainless steel seamless pipes offer excellent cost-effectiveness and longevity, ensuring long-term performance and value for diverse industries.

Utilize reputable online directories that specialize in stainless steel products. These directories often provide comprehensive information about suppliers, including their contact details, product offerings, and customer reviews.

Attend industry-specific trade shows and exhibitions where stainless steel suppliers showcase their products. These events offer an excellent opportunity to connect with multiple suppliers, compare offerings, and establish direct contacts.

Seek recommendations from industry peers, colleagues, or trusted professionals who have experience with stainless steel seamless pipes. Their insights can guide customers to reputable suppliers known for their quality products and reliable services.

Engage with industry associations and organizations related to stainless steel and pipe manufacturing. These associations can provide valuable resources, networking opportunities, and supplier directories to aid in the search for reputable suppliers.

Explore online platforms and marketplaces that connect buyers with verified suppliers. These platforms often have review systems, ensuring transparency and reliability in supplier selection.

Check with local stainless steel suppliers and distributors who specialize in cold-rolled seamless pipes. Local suppliers can offer personalized service, quicker delivery times, and convenient access to their product inventory.

Visit the official websites of stainless steel pipe manufacturers. These websites typically provide detailed product information, technical specifications, and contact information for sales inquiries.

Remember, when selecting a supplier, consider factors such as product quality, certifications, delivery capabilities, customer support, and pricing. Conduct thorough research, request samples or specifications, and engage in direct communication to ensure a reliable and reputable supplier that meets specific needs.

Note: Customers can find reputable suppliers of cold-rolled stainless steel seamless pipes through various channels, including online directories, trade shows, referrals, industry associations, online platforms, local suppliers, and manufacturer websites.

In summary, a cold-rolled seamless stainless steel pipe is a type of stainless steel pipe that undergoes a cold rolling process to enhance its properties and achieve a seamless construction. It offers several advantages over other types of stainless steel pipes, including improved dimensional accuracy, superior surface finish, and enhanced mechanical strength.

When considering cold-rolled stainless steel seamless pipes, customers should be aware of the available sizes, dimensions, and specifications. These pipes come in various standard sizes, ranging from small diameters to larger ones, and are commonly available in grades such as 304 and 316 stainless steel.

Key properties and characteristics of cold-rolled stainless steel seamless pipes include corrosion resistance, high temperature resistance, excellent durability, and low maintenance requirements. These pipes are suitable for various applications, including in industries such as oil and gas, chemical processing, automotive, and construction.

In terms of cost-effectiveness and longevity, cold-rolled stainless steel seamless pipes are a favorable choice. While they may have a higher initial cost compared to other types of stainless steel pipes, their long-term benefits, such as reduced maintenance and extended service life, make them a cost-effective solution.

To find reputable suppliers of cold-rolled stainless steel seamless pipes, customers can utilize online directories, attend trade shows, seek referrals, engage with industry associations, explore online platforms and marketplaces, consider local suppliers and distributors, and visit manufacturer websites. Conducting thorough research, evaluating product quality and certifications, and establishing direct communication with suppliers are crucial steps in finding reliable and reputable sources.

Overall, cold-rolled seamless stainless steel pipes offer superior performance, durability, and aesthetic appeal, making them a preferred choice for various industrial and commercial applications.

Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours