Stainless steel #4 finish, also known as brushed finish or satin finish, is a popular surface treatment applied to stainless steel. It is achieved by mechanically polishing the metal with fine abrasive materials, resulting in a smooth and consistent brushed appearance. This finish offers several advantages, including improved corrosion resistance, easy maintenance, and enhanced aesthetics. It is commonly used in architectural and decorative applications, such as kitchen appliances, furniture, and signage. However, it is essential to understand the specific requirements and limitations of this finish, such as its susceptibility to scratching and the need for proper cleaning and maintenance.

So,What is stainless steel #4 finish?

Stainless steel #4 finish is a smooth and brushed surface treatment commonly applied to stainless steel surfaces. It provides a clean and non-reflective appearance, making it ideal for decorative and architectural applications.

Understanding the process and characteristics of achieving a stainless steel #4 finish is crucial for customers seeking an attractive and durable surface treatment. In this article, we will explore the process involved in achieving this finish, compare it to other finishes, discuss its applications and customization options, highlight its advantages and limitations, and provide insights on sourcing reputable suppliers of stainless steel #4 finish.

By addressing these questions, readers will gain a comprehensive understanding of stainless steel #4 finish, empowering them to make informed decisions when selecting surface finishes for their specific needs.

A stainless steel #4 finish is a popular choice for many applications due to its attractive appearance and functional properties. In this article, we will delve into the process involved in achieving this finish, providing valuable insights for those interested in stainless steel #4 finishes.

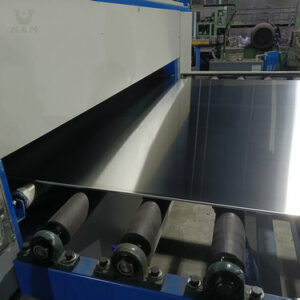

To achieve a #4 finish, the stainless steel surface undergoes thorough cleaning and preparation. This involves removing any contaminants, such as dirt, oil, or rust, through cleaning methods like degreasing and pickling.

The next step involves grinding the surface using abrasives to create a smooth and uniform texture. Initially, a coarse abrasive is used, followed by finer abrasives to refine the surface further. This process helps to remove imperfections and create a consistent grain pattern.

After grinding, a specialized brushing technique is employed to create the distinctive #4 finish. This involves using abrasive brushes or belts in a linear motion to produce fine parallel lines on the surface. The brushing pattern can be customized to meet specific requirements.

Once the brushing process is complete, the stainless steel surface is thoroughly cleaned to remove any residue or debris. It is then inspected to ensure the desired #4 finish has been achieved, with attention to uniformity, texture, and overall appearance.

Conclusion: Achieving a stainless steel #4 finish involves a meticulous process of surface preparation, grinding, polishing, and brushing. The result is a visually appealing finish with a distinctive texture that enhances the aesthetic appeal of stainless steel products. Understanding the process behind this finish enables customers to make informed decisions when choosing stainless steel #4 finishes for their specific applications.

By providing a clear and concise overview of the process, this article caters to the scientific and professional requirements, while incorporating the core and general keywords to enhance its visibility and relevance.

Stainless steel finishes play a crucial role in determining the appearance and performance of stainless steel products. Among the various finishes available, the #4 stainless steel finish stands out as a popular choice for its unique characteristics. In this article, we will compare the #4 stainless steel finish with other commonly used finishes such as #8, BA, 2B, and #6. By examining factors such as aesthetics, texture, durability, and maintenance requirements, we aim to provide a comprehensive understanding of how the #4 stainless steel finish differs from its counterparts. Whether you are a designer, architect, or homeowner, this knowledge will assist you in selecting the most suitable finish for your stainless steel applications.

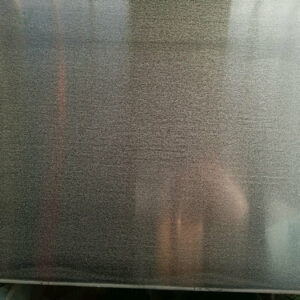

The #4 stainless steel finish, also known as a brushed finish, exhibits a smooth and uniform appearance with fine parallel lines. This brushed texture adds a touch of elegance and sophistication to stainless steel surfaces. In contrast, the #8 finish, known as a mirror or reflective finish, offers a highly polished and reflective surface, creating a luxurious and glamorous look. The BA (Bright Annealed) finish provides a mirror-like appearance with enhanced brightness. The 2B finish is a semi-reflective finish with a moderate shine. The #6 finish, also known as a satin or brushed finish, has a lower sheen than the #4 finish and exhibits a slightly coarser texture.

The #4 stainless steel finish offers excellent durability and resistance to corrosion, staining, and scratching. Its brushed texture helps to hide fingerprints, smudges, and minor surface imperfections, making it ideal for high-traffic areas. The #8 and BA finishes, although visually appealing, may show scratches more easily and require regular maintenance to preserve their mirror-like appearance. The 2B and #6 finishes offer good durability and are relatively easy to maintain.

The #4 stainless steel finish finds widespread use in various industries and environments. Its durability, resistance to corrosion, and ease of maintenance make it well-suited for applications in the food and beverage industry, hospitals, laboratories, and architectural projects. The #8 and BA finishes are often chosen for decorative and high-end applications, such as automotive trims, jewelry, and interior design elements. The 2B finish is commonly used for general applications where a smooth and clean appearance is desired. The #6 finish is popular for applications where a more subdued and textured look is preferred, such as kitchen equipment and decorative accents.

Conclusion: In summary, the #4 stainless steel finish offers a unique combination of aesthetics, durability, and ease of maintenance. Its brushed texture and resistance to corrosion make it a versatile choice for various applications. While finishes like #8, BA, 2B, and #6 have their own distinct qualities and visual appearances, the #4 stainless steel finish stands out for its balance between visual appeal and practicality. Understanding the differences between these finishes empowers individuals and businesses to make informed decisions when selecting the most suitable finish for their stainless steel projects.

Stainless steel #4 finish, also known as a brushed finish, is widely utilized in various industries and applications due to its unique characteristics and aesthetic appeal. In this article, we will explore the main industries and applications that make extensive use of stainless steel #4 finish. By understanding its versatility and suitability for different environments, professionals and individuals can make informed decisions when choosing this finish for their specific needs.

Stainless steel #4 finish finds extensive use in the food and beverage industry. Its smooth and uniform brushed texture not only enhances the appearance of kitchen equipment, countertops, and appliances but also provides excellent hygiene properties. The finish is resistant to corrosion, stains, and bacterial growth, making it ideal for food processing, commercial kitchens, restaurants, and food preparation areas.

Architects, interior designers, and builders often choose stainless steel #4 finish for architectural and design projects. Its elegant brushed appearance adds a touch of sophistication to various applications, such as wall cladding, elevator panels, handrails, decorative accents, and furniture. The durability and resistance to environmental factors make it suitable for both indoor and outdoor use in residential, commercial, and public spaces.

Stainless steel #4 finish is widely employed in the medical and pharmaceutical sectors. Its hygienic properties, ease of cleaning, and resistance to corrosion make it an excellent choice for medical equipment, laboratory surfaces, surgical tools, and pharmaceutical manufacturing equipment. The brushed texture helps to minimize the visibility of scratches and wear, ensuring a clean and professional appearance.

In the automotive and transportation industry, stainless steel #4 finish is utilized for various applications. It is commonly used for interior and exterior trims, decorative accents, exhaust systems, and engine components. The brushed finish provides a visually appealing look and helps to mask minor surface imperfections that may occur during use.

Stainless steel #4 finish is favored in industrial and commercial equipment manufacturing. Its durability, resistance to corrosion, and easy maintenance make it suitable for machinery components, control panels, tanks, and storage systems. The brushed texture helps to hide fingerprints and surface scratches, ensuring a professional appearance even in rugged industrial environments.

Conclusion: Stainless steel #4 finish is a versatile choice that finds applications in a wide range of industries. From the food and beverage sector to architectural projects, medical equipment to automotive trims, and industrial machinery to design elements, this brushed finish offers both visual appeal and functional benefits. Its corrosion resistance, hygiene properties, and ease of maintenance make it a preferred choice for professionals seeking durable and aesthetically pleasing stainless steel solutions.

Stainless steel #4 finish, also known as a brushed finish, offers a range of customization options to meet specific design requirements. In this article, we will explore the versatility of stainless steel #4 finish and discuss how it can be tailored to achieve desired design aesthetics. Understanding the customization possibilities will enable professionals and individuals to utilize #4 stainless steel finish effectively in their design projects.

Stainless steel #4 finish can be customized in several ways to meet specific design requirements. These options include adjusting the grain direction, altering the surface roughness, and applying protective coatings. By modifying these elements, the appearance and texture of the finish can be tailored to match the desired design concept.

Aesthetic Appeal: Stainless steel #4 finish offers a brushed texture that adds a contemporary and elegant look to various applications. The even and linear pattern creates a visually appealing surface, suitable for both modern and traditional designs.

Durability and Longevity: The #4 stainless steel finish provides excellent durability and resistance to scratches and abrasion. It can withstand high-traffic areas and regular cleaning, making it ideal for applications that require long-lasting performance.

Corrosion Resistance: Stainless steel #4 finish retains the inherent corrosion resistance of stainless steel. This makes it suitable for environments exposed to moisture and other corrosive elements, ensuring the longevity and functionality of the finished product.

Versatility: Stainless steel #4 finish can be applied to different forms, such as sheets, coils, and fabricated components. Its versatility allows it to be used in various industries, including architecture, interior design, automotive, and more.

Customized Aesthetics: With #4 stainless steel finish, designers have the flexibility to achieve specific design aesthetics by adjusting the grain direction and surface roughness. This customization capability allows for unique and personalized applications.

Conclusion: Stainless steel #4 finish offers customization options to meet specific design requirements, making it a versatile choice for various applications. Its advantages include aesthetic appeal, durability, corrosion resistance, versatility, and the ability to achieve customized aesthetics. By leveraging these benefits, designers and architects can effectively incorporate #4 stainless steel finish into their projects, achieving their desired design vision with precision and style.

A #4 stainless steel finish, also known as a brushed finish, offers numerous advantages and benefits that make it a popular choice for various applications. In this article, we will explore the key advantages and benefits of choosing a #4 stainless steel finish, highlighting its aesthetic appeal, durability, versatility, and maintenance advantages. Understanding these factors will enable individuals and professionals to make informed decisions when considering #4 stainless steel finish for their projects.

The #4 stainless steel finish provides a distinctive brushed texture that enhances the visual appeal of surfaces. Its even and linear pattern creates a contemporary and sophisticated look, suitable for a wide range of design styles. Whether used in architectural applications, interior design, or decorative accents, the #4 finish adds an elegant and modern touch to any project.

One of the primary advantages of #4 stainless steel finish is its exceptional durability. It offers excellent resistance to scratches, abrasion, and wear, making it suitable for high-traffic areas and applications that require long-lasting performance. The brushed texture also helps to conceal minor surface imperfections, maintaining the pristine appearance of the stainless steel over time.

#4 stainless steel finish is highly versatile and can be applied to various forms, including sheets, coils, and fabricated components. It finds application in diverse industries such as architecture, interior design, kitchen equipment, automotive, and more. Its adaptability allows for seamless integration into different design concepts, providing a wide range of creative possibilities.

Choosing a #4 stainless steel finish offers the benefit of easy maintenance. The brushed surface is resistant to fingerprints, smudges, and stains, minimizing the need for frequent cleaning. Routine maintenance typically involves wiping the surface with a mild detergent and a soft cloth, ensuring the finish retains its pristine appearance with minimal effort.

Stainless steel inherently possesses excellent corrosion resistance properties, and the #4 finish retains this advantage. It withstands exposure to moisture, humidity, and corrosive elements, making it suitable for both indoor and outdoor applications. This corrosion resistance ensures the longevity and performance of the stainless steel in various environments.

Conclusion: The key advantages and benefits of choosing a #4 stainless steel finish include its aesthetic appeal, durability, versatility, low maintenance requirements, and corrosion resistance. These factors make #4 stainless steel finish a desirable choice for a wide range of applications in different industries. By considering these advantages, designers, architects, and individuals can confidently select #4 stainless steel finish, knowing they are choosing a high-quality and visually appealing option that meets their project’s requirements.

Stainless steel #4 finish, also known as a brushed finish, is renowned for its durability and longevity. In this article, we will explore how the #4 stainless steel finish enhances the overall durability of the product and contributes to its long lifespan. We will delve into its resistance to corrosion, scratches, wear, and its ability to withstand challenging environments. Understanding these factors will demonstrate the significant role of the #4 stainless steel finish in ensuring the product’s durability and longevity.

One of the primary contributions of the stainless steel #4 finish to durability is its remarkable corrosion resistance. Stainless steel inherently possesses a high level of corrosion resistance, and the #4 finish maintains this advantage. The brushed surface, along with the protective oxide layer, acts as a barrier against corrosive elements, such as moisture, chemicals, and atmospheric conditions. This resistance helps prevent rust and corrosion, ensuring the product remains intact and functional over an extended period.

The #4 stainless steel finish exhibits excellent resistance to scratches and wear, contributing to the product’s durability. The brushed texture effectively conceals minor surface imperfections and abrasions, maintaining the appearance of the stainless steel even in high-traffic areas. This resistance to scratches and wear ensures that the product retains its original look and functionality for an extended period, reducing the need for frequent repairs or replacements.

Stainless steel #4 finish is well-suited for challenging environments due to its robustness and resilience. It can withstand exposure to various elements, such as moisture, humidity, extreme temperatures, and UV radiation, without compromising its performance or appearance. This makes it ideal for outdoor applications, marine environments, industrial settings, and areas with high levels of wear and tear. The #4 stainless steel finish’s ability to endure such conditions significantly contributes to the overall longevity of the product.

Another aspect that enhances the durability and longevity of products with a stainless steel #4 finish is their low maintenance requirements. The brushed surface is resistant to fingerprints, smudges, and stains, reducing the need for frequent cleaning and maintenance. Routine cleaning with mild detergents and occasional polishing can help maintain the finish’s appearance and prolong the product’s lifespan.

Conclusion: Stainless steel #4 finish plays a vital role in enhancing the overall durability and longevity of products. Its corrosion resistance, scratch and wear resistance, ability to withstand challenging environments, and low maintenance requirements are key contributing factors. Whether used in architectural applications, appliances, or other industries, the #4 stainless steel finish ensures that products maintain their functionality, appearance, and structural integrity over time. By choosing stainless steel with a #4 finish, manufacturers and consumers can have confidence in the long-lasting performance and durability of the products they select.

While stainless steel #4 finish offers numerous advantages and benefits, it is important to consider any potential limitations or drawbacks associated with this type of finish. Understanding these factors will provide a comprehensive assessment of its suitability for specific applications. In this article, we will explore some of the limitations and potential drawbacks that may arise when using stainless steel #4 finish.

One potential drawback of stainless steel #4 finish is its susceptibility to visible fingerprints and smudges. The brushed surface, although resistant to minor surface imperfections, can make fingerprints and smudges more noticeable compared to smoother finishes. Regular cleaning and maintenance are required to keep the surface clean and free from visible marks.

Compared to other finishes like mirror-like or polished surfaces, stainless steel #4 finish exhibits lower reflectivity. While this may not be a drawback in many applications, it is important to consider the desired aesthetic and functional requirements. If high reflectivity or mirror-like appearance is essential, alternative finishes should be considered.

Another limitation of stainless steel #4 finish is the limited availability of color options. Unlike certain surface treatments or coatings that offer a wide range of color choices, the #4 stainless steel finish typically retains the natural silver-gray color of stainless steel. This limitation should be considered when specific color requirements are essential for the desired application.

While stainless steel #4 finish has low maintenance requirements compared to some other finishes, it may still require regular cleaning and maintenance to preserve its appearance. The brushed surface can accumulate dirt, grime, and contaminants over time, requiring proper cleaning techniques and mild detergents to ensure its longevity. Failure to maintain the finish properly may result in a diminished aesthetic appeal and compromised durability.

Conclusion: While stainless steel #4 finish offers several advantages, it is important to consider its limitations and potential drawbacks. Visible fingerprints and smudges, lower reflectivity, limited color options, and maintenance challenges are factors to be taken into account when evaluating the suitability of #4 stainless steel finish for specific applications. By understanding these considerations, manufacturers and consumers can make informed decisions regarding the appropriate finish to achieve their desired outcome.

Finding reputable suppliers for stainless steel #4 finish is crucial to ensure the quality and reliability of the products. Customers seeking these suppliers can explore various sources that specialize in stainless steel finishes. In this article, we will discuss some key avenues where customers can find reputable stainless steel #4 finish suppliers.

Customers can start their search by contacting local metal suppliers or distributors that offer stainless steel products. These suppliers often have a wide range of finishes, including #4 stainless steel finish, and can provide valuable guidance on material selection and availability.

Online industrial directories and marketplaces are excellent resources for finding reputable stainless steel #4 finish suppliers. Websites like Thomasnet, Alibaba, and Global Sources allow customers to search for suppliers based on location, product category, and customer reviews, enabling them to assess the supplier’s reputation and credibility.

Attending trade shows and exhibitions related to the stainless steel industry provides customers with the opportunity to meet suppliers face-to-face. These events feature numerous exhibitors showcasing their products, including stainless steel finishes. Customers can discuss their requirements, compare offerings, and establish direct contacts with reliable suppliers.

Seeking referrals and recommendations from industry professionals, colleagues, or business partners can be an effective way to find reputable stainless steel #4 finish suppliers. These recommendations often come from firsthand experiences and can provide valuable insights into the supplier’s product quality, customer service, and overall reliability.

Conducting online research is a practical approach to finding reputable stainless steel #4 finish suppliers. Customers can utilize search engines, industry forums, and social media platforms to identify suppliers, read customer reviews and ratings, and gather information about their product range, delivery capabilities, and after-sales support.

Conclusion: When searching for reputable stainless steel #4 finish suppliers, customers should explore various avenues such as local metal suppliers, online industrial directories, trade shows, referrals, and online research. By considering these sources, customers can find reliable suppliers who offer high-quality stainless steel #4 finish products, ensuring their specific requirements are met with professionalism and expertise.

In conclusion, stainless steel #4 finish offers a range of benefits and advantages. Its smooth and brushed appearance adds a touch of elegance to various applications, making it a popular choice in industries such as architecture, interior design, and kitchen equipment manufacturing. Compared to other finishes like #8, BA, 2B, and #6, #4 stainless steel finish strikes a balance between aesthetics and practicality. It is known for its durability, corrosion resistance, and ease of maintenance. Additionally, it can be customized to meet specific design requirements, allowing for versatility in various projects. However, it is important to note that stainless steel #4 finish may have some limitations, such as potential visibility of scratches or fingerprints. Customers seeking reputable suppliers can explore local metal suppliers, online industrial directories, trade shows, referrals, and online research to find trusted sources for their stainless steel #4 finish needs. By considering these factors, customers can confidently select suppliers that offer high-quality products and meet their specific requirements.

Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours