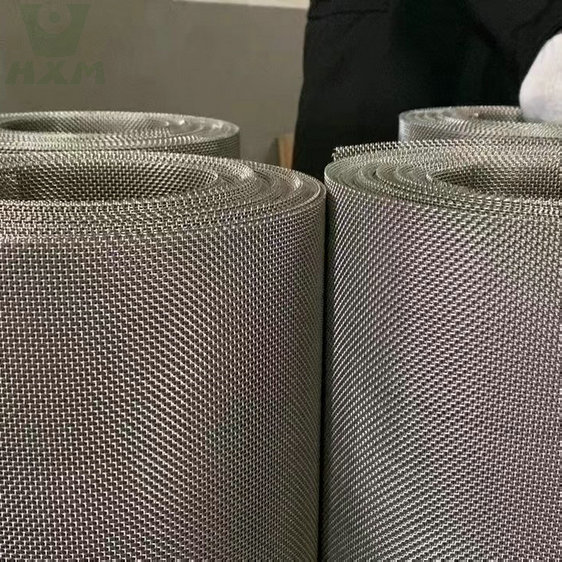

304 Stainless Steel Mesh

Huaxiao Metal Corp offers top-notch 304 Stainless Steel Mesh, renowned for its corrosion resistance and durability. With precision manufacturing and diverse weaving patterns, our meshes cater to a wide range of applications, ensuring reliability and excellence in filtration, chemical processing, and beyond. Trust in quality with Huaxiao Metal Corp.

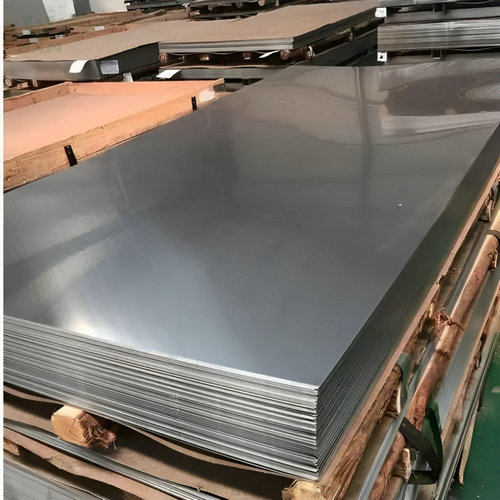

201 stainless steel sheet

201 stainless steel sheet is a type of austenitic stainless steel that belongs to the 200 series, characterized by its chromium and nickel content. It offers a combination of good formability, corrosion resistance, and cost-effectiveness.

Monel Metal vs Stainless Steel

Monel Steel vs Stainless Steel:Monel steel, a nickel-copper alloy, boasts exceptional corrosion resistance, making it ideal for marine and aerospace applications. It is non-magnetic and exhibits good strength at high temperatures. However, it comes at a higher cost. On the other hand, stainless steel, with varying alloys, offers cost-effectiveness, corrosion resistance, and versatility. The choice depends on specific needs, with Monel excelling in corrosive environments, while stainless steel caters to diverse applications economically.

Monel 400

Monel 400 is a nickel-copper alloy known for its excellent corrosion resistance and high temperature strength. It has a wide range of applications in offshore engineering, petrochemicals, etc. The strength and hardness of Monel 400 make it an ideal material to withstand heavy loads and complex environments. At the same time, its excellent corrosion resistance allows it to maintain stable performance in acidic or alkaline environments. In addition, Monel 400 has good machinability and is easy to weld and fabricate. This alloy is particularly suitable for applications that require high corrosion and temperature resistance, such as marine equipment, chemical reactors, heat exchangers, etc. In summary, Monel 400 is an important engineering material due to its excellent properties and is widely used in engineering applications in a variety of extreme environments.

What does PH mean in stainless steel?

What is the pH value of stainless steel? In stainless steel, “PH” stands for “precipitation hardening.” Precipitation-hardened stainless steels are a class of stainless steel alloys known for their ability to be enhanced through heat treatment processes. This process is also known as age hardening or precipitation strengthening.

Is stainless steel stronger than aluminum?

Is stainless steel stronger than aluminum?Stainless steel is generally stronger than aluminum, offering higher tensile and yield strength, but it’s also denser.

Is 410 stainless steel magnetic

Yes, 410 stainless steel magnetic. The reason for its magnetic properties lies in its microstructure. Stainless steels can be broadly categorized into two groups: ferritic and austenitic. 410 stainless steel is part of the ferritic stainless steel group.

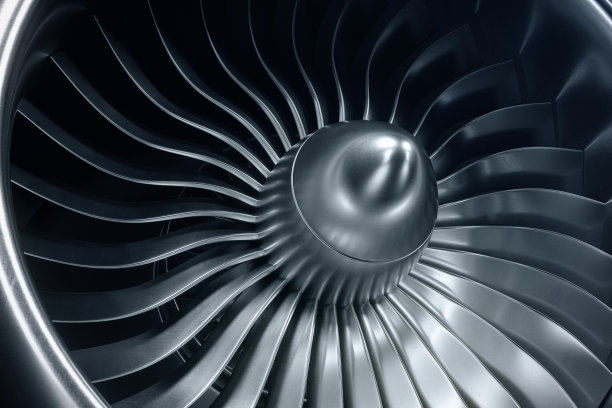

GH4169 High temperature resistant alloy

GH4169 high-temperature alloy has excellent strength and corrosion resistance, used in aerospace and industrial applications.

3J1 elastic alloy

3J01 elastic alloy, also known as spring alloy, is prized for its high elastic modulus, excellent spring properties, thermal stability, and corrosion resistance. It’s ideal for demanding applications requiring superior spring performance.

What is t1 steel?

T1 steel, also known as tungsten high-speed steel, is a high-alloy tool steel. It is recognized for its exceptional wear resistance and hardness. T1 steel is commonly used in cutting tools, such as drills and milling cutters, where high-speed machining and maintaining sharp cutting edges are crucial.