Once upon a time, in a bustling city known for its architectural marvels, there stood a majestic stainless steel structure. Its gleaming surface reflected the sunlight, captivating the eyes of all who passed by. However, the city’s creative minds wondered, “Can stainless steel be painted?” They yearned to add a touch of vibrant color and artistic expression to the resilient material.

Artists, architects, and even everyday dreamers eagerly awaited the answer, hoping to transform the stainless steel marvel into a mesmerizing masterpiece. Little did they know that the journey to unlock stainless steel’s painting potential would not only unveil a world of possibilities but also lead them to the realm of stainless steel suppliers, who held the key to turning their imaginative visions into reality.

So,Can stainless steel be painted?

Yes, stainless steel can be painted using specialized techniques and coatings designed for metal surfaces.

This little story is interesting and brings up the common question of whether stainless steel can be painted. While the problem may seem simple, in reality, it involves many complicated factors and technical details. In the following articles, we will delve deeper into these issues and answer these common but confusing questions for you.

Stainless steel’s versatile nature and durability have always captivated designers and architects. However, the question arises: “What are the different painting methods available for stainless steel surfaces?” This article delves into the realm of stainless steel painting, providing a comprehensive understanding of the various techniques and processes. From decorative stainless steel sheets to the renowned SUS 304 stainless steel, we explore how stainless steel suppliers play a vital role in offering suitable materials for a successful painting endeavor. So, let us embark on a journey to discover the scientific intricacies and creative possibilities that lie within the world of stainless steel surface painting.

Stainless steel exhibits exceptional corrosion resistance, high strength, and an attractive appearance. Its smooth, non-porous surface prevents the penetration of moisture, making it suitable for various applications.

The composition and surface condition of stainless steel, such as the presence of oxide layers or contaminants, affect paint adhesion. Factors like surface roughness, surface energy, and surface preparation techniques play a crucial role in ensuring paint compatibility and long-term durability.

Thorough cleaning of stainless steel surfaces is essential to remove dirt, grease, and oils. Techniques like solvent cleaning, alkaline cleaning, or abrasive cleaning can be employed to achieve a clean and contaminant-free surface.

Removing contaminants ensures proper paint adhesion and prevents coating failures. Surface preparation techniques like mechanical abrasion, acid etching, or chemical passivation help enhance the surface profile and promote paint adhesion.

Brushing and rolling methods are commonly used for smaller-scale projects or areas that require precision. These techniques allow for controlled paint application and even coverage.

Spray painting is suitable for larger surfaces or when a consistent and smooth finish is desired. It ensures efficient coverage, uniformity, and faster application.

Powder coating involves applying dry powder onto the stainless steel surface, which is then cured through heat to form a protective and decorative coating. This method offers excellent durability, color options, and resistance to chipping and fading.

Electrostatic painting involves electrically charging the paint particles, which are then attracted to the grounded stainless steel surface. This method ensures even coverage, minimal overspray, and precise application.

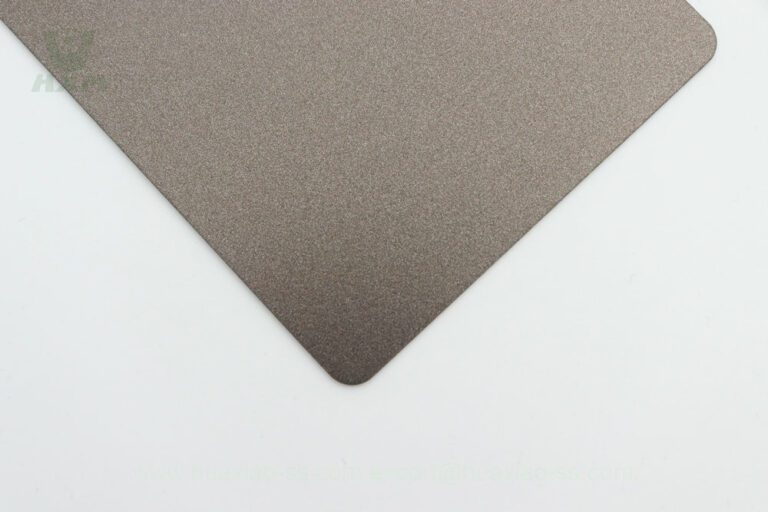

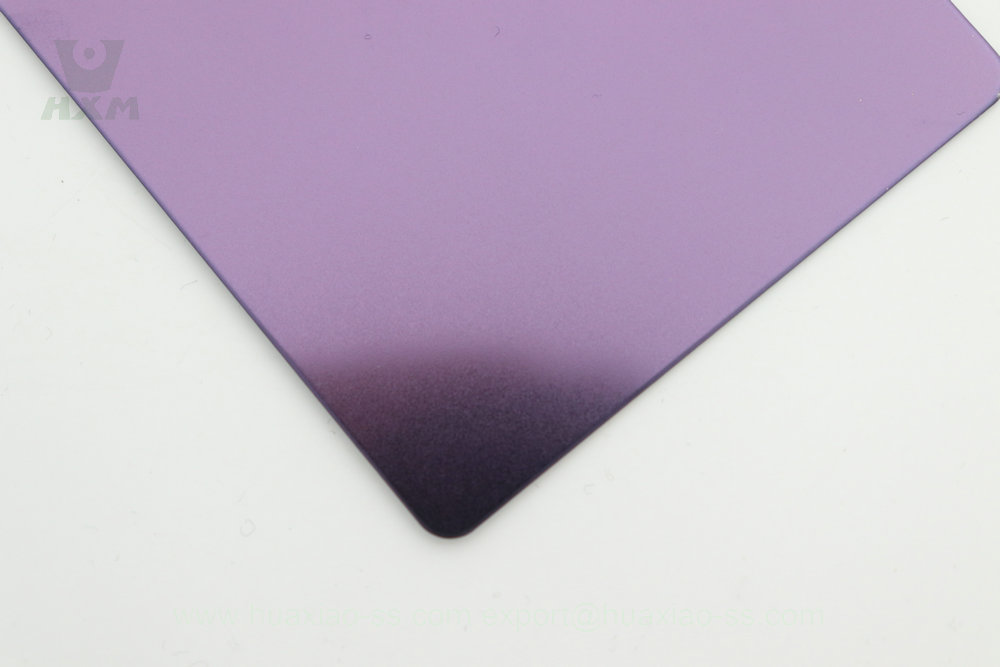

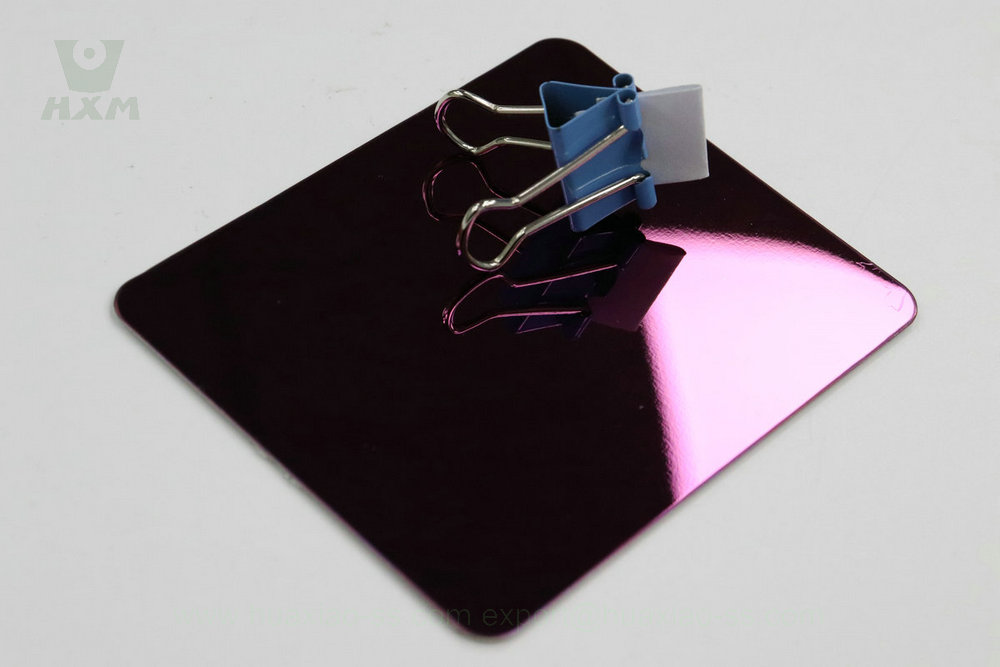

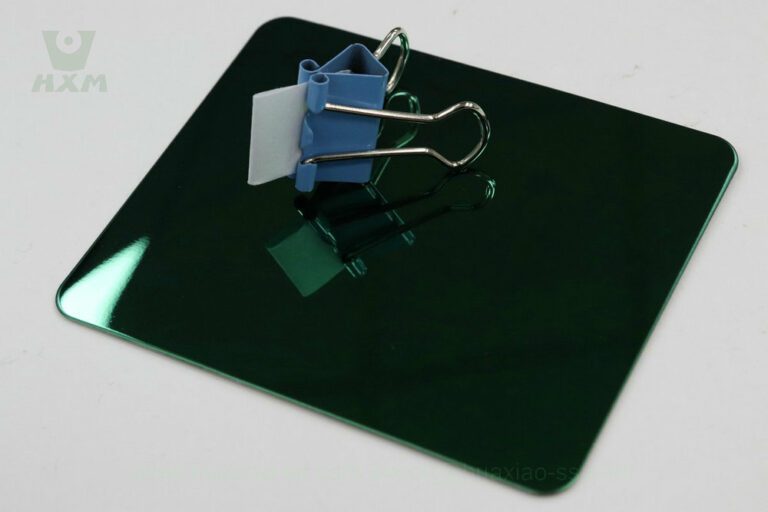

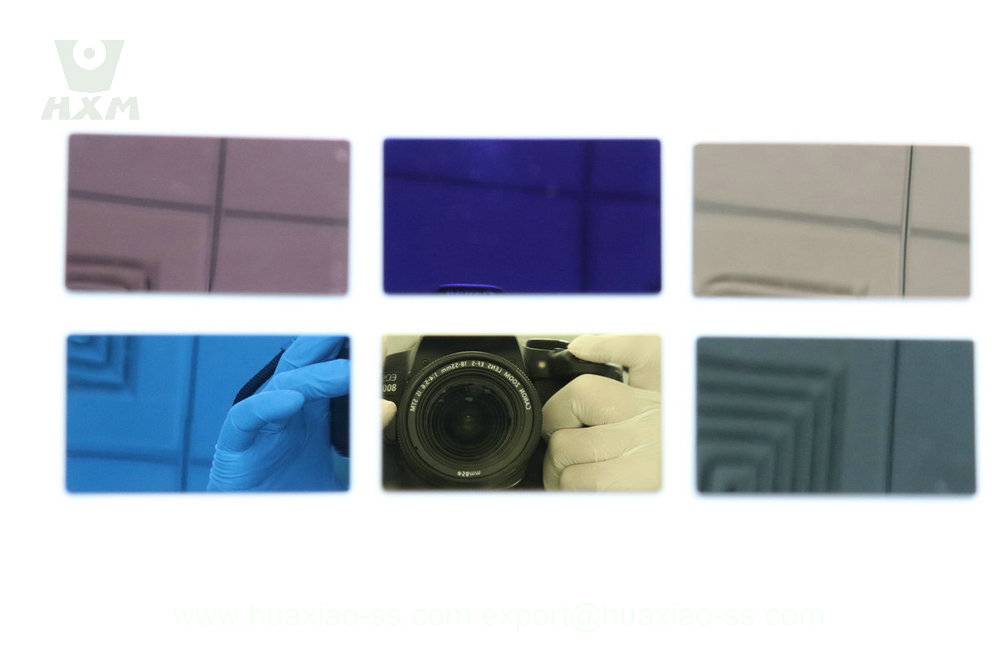

Decorative stainless steel sheets with various surface finishes, patterns, and textures can be used to create visually appealing and unique designs. These sheets enhance the aesthetic appeal of stainless steel surfaces in architectural, interior design, and artistic applications.

Embossing, etching, or laser engraving can be employed to create patterns, textures, or customized designs on stainless steel surfaces. Additionally, techniques like PVD coating or patination can be used to introduce colors and visual effects.

Decorative techniques and coatings should not compromise the corrosion resistance and mechanical properties of stainless steel. Care should be taken to select methods that maintain the integrity of the stainless steel while adding aesthetic value.

Stainless steel suppliers play a crucial role in assisting customers in selecting the right stainless steel materials for their painting projects. They provide expertise in material selection based on the intended application, surface finish, and compatibility with paints and coatings.

Suppliers offer a diverse range of stainless steel grades, finishes, and sizes, allowing customers to find the most suitable material for their specific painting requirements. This ensures compatibility between the stainless steel and the chosen paint system.

Reputable stainless steel suppliers adhere to industry standards and regulations, ensuring the materials they provide meet quality and performance requirements. This helps customers achieve successful painting outcomes that meet industry standards and expectations.

In conclusion, the ability to paint stainless steel surfaces opens up a world of design possibilities. From decorative stainless steel sheets to the resilient SUS 304 stainless steel, various painting methods can enhance aesthetics while maintaining the material’s durability. Stainless steel suppliers serve as valuable partners, offering guidance and a diverse range of materials to support successful painting projects. With a thorough understanding of the available techniques and careful consideration of suitable paints, designers and architects can unlock the full potential of stainless steel in their creative endeavors.

Imagine a sleek and modern stainless steel sculpture standing proudly in a vibrant public plaza. Its smooth surface reflects the sunlight, exuding a sense of elegance and sophistication. Now, imagine this stainless steel sculpture adorned with a vibrant paint color that perfectly complements its surroundings, adding a captivating visual element to the space. The right paint color can transform stainless steel from a utilitarian material into a work of art. However, choosing the ideal paint color for stainless steel requires careful consideration. It involves understanding the unique properties of stainless steel, harmonizing with the environment and design, and taking practical factors into account. In this article, we will explore the essential considerations to help you select the perfect paint color for your stainless steel projects.

Stainless steel has a reflective surface that interacts with light, influencing the perception of color. It’s important to consider how the chosen paint color will interact with the stainless steel’s reflective properties.

Selecting a paint color that is resistant to fading, discoloration, and degradation ensures the long-term aesthetic appeal of the stainless steel surface. Consider paints with UV stability and high-quality pigments for optimal color retention.

Consider the overall color palette and aesthetics of the environment where the stainless steel will be located. Choose a paint color that harmonizes with the surrounding elements, such as building facades, interior design, or landscape features.

Paint color can evoke specific emotions or align with branding strategies. Consider the desired mood or brand identity when selecting a paint color. For example, vibrant colors may convey energy and creativity, while neutral tones evoke a sense of sophistication.

Dark colors tend to absorb more heat, which may affect the stainless steel’s temperature and thermal expansion. Consider the environmental conditions and potential thermal effects when selecting paint colors, especially for outdoor applications.

Certain paint colors may show dirt, stains, or smudges more prominently than others. Take into account the ease of maintenance and cleaning when choosing a paint color, particularly for surfaces exposed to high traffic or environmental pollutants.

Obtain paint color samples and create mock-ups to evaluate how the chosen color will appear on stainless steel. Test the color under different lighting conditions and angles to ensure it meets the desired aesthetic outcome.

If using decorative stainless steel sheets, consider how the paint color interacts with the sheet’s surface finish, patterns, or textures. Ensure the paint color complements and enhances the overall decorative effect.

Consult with stainless steel suppliers who have experience with painting stainless steel surfaces. They can provide guidance on suitable paint colors, finishes, and application techniques based on their industry expertise and knowledge.

Stainless steel suppliers often have partnerships with paint manufacturers or can recommend reliable paint suppliers. They can provide access to a diverse range of paint colors and systems, ensuring compatibility with stainless steel surfaces.

Ensure the chosen paint color complies with industry standards and regulations, especially for applications where safety or specific performance requirements need to be met. Stainless steel suppliers can assist in ensuring compliance with relevant standards.

By carefully considering the reflective properties of stainless steel, harmonizing with the environment and design, taking practical factors into account, conducting testing, and seeking guidance from stainless steel suppliers, you can make informed decisions when selecting a paint color for stainless steel surfaces.

Painting SUS 304 stainless steel offers a way to enhance its appearance and provide additional protection. However, there are certain limitations and challenges that need to be considered when undertaking such a project. This article explores the potential obstacles and provides insights into overcoming them.

SUS 304 stainless steel’s low surface energy can pose challenges for paint adhesion. The passive chromium oxide layer, while providing corrosion resistance, can make it difficult for paint to adhere effectively. Thorough surface preparation, including cleaning, degreasing, and roughening, is essential to promote adhesion.

The reflective nature of stainless steel can affect the perceived color of the paint, leading to variations compared to other substrates. Careful consideration must be given to color selection to ensure the desired visual outcome. Testing paint samples on a small area is recommended to assess the final appearance.

The performance and longevity of the painted surface can be influenced by environmental conditions and usage. Exposure to chemicals, extreme temperatures, and high humidity may impact paint adhesion and durability. Choosing high-quality paints formulated for stainless steel and considering the intended application environment are crucial for long-term performance.

Proper surface preparation, including cleaning, degreasing, and roughening, is essential to create an ideal surface for paint adhesion. Additionally, using a primer specifically designed for stainless steel can enhance paint adhesion and durability.

Collaborating with experienced stainless steel suppliers can provide valuable insights and recommendations tailored to the project’s requirements. They can offer guidance on paint selection, surface preparation techniques, and environmental considerations.

Conclusion: Painting SUS 304 stainless steel presents some limitations and challenges due to its low surface energy, potential color variation, and environmental factors. However, by implementing thorough surface preparation, selecting suitable paints, and seeking expert guidance from stainless steel suppliers, these challenges can be overcome. With the right approach, a visually appealing and durable painted finish can be achieved, enhancing the aesthetics and protection of SUS 304 stainless steel components or structures.

Decorative stainless steel sheets offer a unique blend of functionality and aesthetics, making them popular in various architectural and design applications. The question arises whether these sheets can be painted without compromising their inherent beauty. This article examines the feasibility of painting decorative stainless steel sheets while maintaining their visual appeal.

Decorative stainless steel sheets are specifically designed to enhance visual appeal. They feature intricate patterns, textures, and finishes that contribute to their aesthetic value. It is crucial to consider the impact of paint on these unique characteristics.

Selecting the right paint is essential to maintain the aesthetic appeal of decorative stainless steel sheets. Compatibility testing is recommended to ensure the paint adheres well to the surface without adversely affecting the sheet’s appearance. Proper surface preparation, including cleaning and removing any contaminants, is vital for optimal paint adhesion.

Choosing the appropriate paint color is crucial for preserving the visual harmony of decorative stainless steel sheets. The color should complement the existing patterns and finishes, enhancing the overall aesthetic appeal. Careful consideration and testing of color samples are necessary to achieve the desired effect.

Paint application techniques play a significant role in maintaining the sheet’s aesthetic appeal. Care must be taken to ensure an even and uniform coat of paint, avoiding drips, streaks, or uneven coverage. Precision and attention to detail are essential to preserve the original design elements.

Applying protective coatings or clear finishes can help safeguard the painted decorative stainless steel sheets. These coatings provide an additional layer of protection against scratches, fading, and chemical damage while enhancing the longevity of the painted surface.

Collaborating with reputable stainless steel suppliers can provide invaluable assistance in the painting process. They can offer expertise on paint compatibility, surface preparation techniques, color selection, and protective coatings. Leveraging their knowledge and experience ensures optimal results without compromising the sheet’s aesthetic appeal.

Conclusion: Painting decorative stainless steel sheets while preserving their aesthetic appeal requires careful consideration of paint compatibility, surface preparation, color selection, application techniques, and protective coatings. By following these guidelines and seeking guidance from reliable stainless steel suppliers, it is possible to achieve a painted finish that enhances the visual allure of decorative stainless steel sheets. With the right approach, the sheets can retain their inherent beauty while benefiting from the additional customization and protection offered by paint.

Painted stainless steel surfaces offer an excellent combination of aesthetics and functionality. However, the choice of paint or coating plays a crucial role in determining the durability and longevity of the painted finish. This article explores how the selection of paint or coating affects the performance and lifespan of painted stainless steel.

Various paint and coating options are available for painting stainless steel surfaces. These include epoxy coatings, acrylic paints, polyurethane coatings, and powder coatings. Understanding their properties and characteristics is essential for making informed decisions.

Factors such as exposure to UV radiation, moisture, temperature fluctuations, and chemical exposure can impact the durability of the painted stainless steel surface. Choosing a paint or coating that offers excellent resistance to these factors is crucial for long-term performance.

The adhesion and bonding properties of the paint or coating are critical for ensuring its longevity. The paint should adhere well to the stainless steel surface and form a strong bond to resist peeling, chipping, or flaking over time.

Stainless steel is known for its corrosion resistance, but the painted surface can be vulnerable to corrosion if the paint or coating is not properly selected. Opting for paints or coatings with excellent corrosion resistance helps protect the underlying stainless steel and extends the lifespan of the painted surface.

Exposure to UV radiation can cause color fading and degradation of the painted stainless steel surface. Choosing paints or coatings with UV stability and excellent color retention properties ensures that the painted finish remains vibrant and intact even under prolonged sun exposure.

The ease of maintenance and cleanability of the painted stainless steel surface is another important consideration. Selecting paints or coatings that are easy to clean and maintain helps preserve the appearance and durability of the painted finish.

Working closely with stainless steel suppliers can provide valuable guidance in selecting the most suitable paints or coatings for painted stainless steel applications. They can offer expertise on product compatibility, recommend proven paint systems, and provide technical support throughout the process.

Conclusion: The choice of paint or coating significantly influences the durability and longevity of painted stainless steel surfaces. Factors such as adhesion, corrosion resistance, UV stability, and maintenance play crucial roles in ensuring the painted finish withstands environmental challenges and maintains its aesthetic appeal. By collaborating with reputable stainless steel suppliers and choosing high-quality paints or coatings, it is possible to achieve a durable and long-lasting painted stainless steel surface that enhances both functionality and visual appeal.

Achieving compatibility between stainless steel material and the paint or coating used is crucial for ensuring a successful and long-lasting finish. Stainless steel suppliers play a vital role in ensuring this compatibility by offering expertise, guidance, and quality assurance. This article explores how stainless steel suppliers ensure the compatibility between stainless steel materials and the paint or coating used, resulting in a seamless and durable finish.

Stainless steel suppliers carefully select and provide stainless steel materials that are known for their compatibility with various paints or coatings. These suppliers conduct thorough testing to assess the compatibility of the stainless steel with different paint systems, considering factors such as adhesion, corrosion resistance, and durability.

Based on their expertise and experience, stainless steel suppliers can recommend specific paints or coatings that have proven compatibility with their stainless steel materials. They consider the intended application, environmental conditions, and performance requirements to ensure the selected products meet the desired standards.

Stainless steel suppliers offer technical support to customers, collaborating closely to understand their specific project requirements. They provide guidance on the selection of suitable paints or coatings, taking into account factors such as surface preparation, application techniques, and post-painting considerations.

Stainless steel suppliers often provide detailed coating specifications and standards that outline the requirements for the paint or coating used on their stainless steel materials. These specifications may include surface preparation methods, recommended paint systems, and application guidelines to ensure optimal compatibility and performance.

Reputable stainless steel suppliers adhere to stringent quality assurance measures and certifications. They ensure that the stainless steel materials they supply meet industry standards and are compatible with various paint or coating systems. This commitment to quality ensures that customers receive reliable and compatible stainless steel products.

Stainless steel suppliers collaborate with paint or coating manufacturers to exchange knowledge and expertise. This collaboration helps ensure continuous improvement in paint formulation and compatibility testing, leading to enhanced compatibility between stainless steel and paint systems.

Stainless steel suppliers invest in research and development to stay updated with the latest advancements in paint or coating technology. They actively seek innovative solutions that improve compatibility, durability, and aesthetics, enabling them to provide customers with cutting-edge products and recommendations.

Conclusion: Stainless steel suppliers play a vital role in ensuring the compatibility between stainless steel materials and the paint or coating used. Through material selection, testing, product recommendations, technical support, and collaboration with paint manufacturers, these suppliers ensure a seamless match between stainless steel and paint systems. Their commitment to quality assurance, adherence to standards, and continuous research and development help deliver reliable and compatible solutions, resulting in durable and visually appealing finishes for various applications.

In conclusion, the question “Can stainless steel be painted?” has been thoroughly explored, and the answer is affirmative. Stainless steel can indeed be painted, offering a wide range of design possibilities and aesthetic enhancements. However, there are several considerations to keep in mind when painting stainless steel to ensure the best results.

Firstly, the choice of paint or coating is crucial in determining the durability and longevity of the painted stainless steel. Selecting high-quality paints that are specifically formulated for stainless steel surfaces, considering factors such as weather resistance and chemical compatibility, is essential.

Additionally, the preparation of stainless steel surfaces plays a significant role in the success of the painting process. Proper cleaning, removal of contaminants, and ensuring a suitable surface texture are necessary to achieve optimal adhesion and a smooth finish.

Moreover, when it comes to decorative stainless steel sheets, it is possible to paint them without compromising their aesthetic appeal. Careful selection of paints that can adhere to the surface and techniques such as etching or powder coating can be employed to achieve desired patterns, textures, and colors while preserving the inherent beauty of stainless steel.

To ensure the compatibility between stainless steel and the paint or coating used, stainless steel suppliers play a crucial role. They offer expertise, product recommendations, and technical support, ensuring the selection of suitable materials and providing detailed specifications and standards. Collaboration with paint or coating manufacturers and continuous research and development further contribute to improving compatibility and achieving the best results.

In summary, while painting stainless steel presents its challenges, with proper consideration of paint selection, surface preparation, and collaboration with stainless steel suppliers, it is possible to achieve durable, visually appealing, and long-lasting painted stainless steel surfaces. The versatility and aesthetic potential of painted stainless steel make it a valuable choice for various applications in architecture, design, and industry.

Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours