Stainless steel is not inherently waterproof, but it has good corrosion resistance properties. This means it can withstand exposure to moisture and water without rusting or corroding. However, its ability to resist water largely depends on the grade of stainless steel and the specific environmental conditions. In extremely corrosive or saline environments, even stainless steel can be susceptible to some degree of corrosion. For applications requiring high resistance to water and corrosion, selecting the right grade of stainless steel and proper maintenance are essential.

So,is Stainless Steel Waterproof?

Stainless steel itself does not have the ability to waterproof, but it can be added by special alloy elements and surface treatment, improve its waterproof performance.

This little story is interesting and brings up the common question of whether stainless steel is waterproof. While the problem may seem simple, in reality, it involves many complicated factors and technical details. In the following articles, we will delve deeper into these issues and answer these common but confusing questions for you.

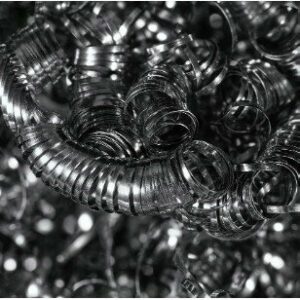

The production of stainless steel begins with the careful selection of raw materials. The primary components include iron ore, chromium, nickel, and other alloying elements such as manganese and molybdenum. These materials are sourced from mines and undergo rigorous testing to ensure quality and consistency.

The first step in stainless steel production is steelmaking. Two primary methods are used:

Electric Arc Furnace (EAF): Scrap metal, including stainless steel scrap, is melted in an electric arc furnace. The heat generated by electric arcs melts the metal, while fluxes and alloying elements are added to achieve the desired composition. The molten metal is then refined and analyzed for quality control.

Basic Oxygen Furnace (BOF): In this method, molten iron from a blast furnace is combined with scrap steel and oxygen is blown through the mixture. The impurities in the molten metal react with the oxygen, forming slag that is separated from the steel. Alloying elements are added to achieve the desired stainless steel grade.

The molten steel is transferred to an AOD converter where oxygen and argon gases are blown through it. This process reduces the carbon content and controls the levels of alloying elements, ensuring the desired stainless steel properties.

The refined molten steel is cast into solid form using a continuous casting process. It is poured into a water-cooled mold and solidifies into long billets or slabs.

The billets or slabs are reheated and passed through hot rolling mills, where they are reduced in thickness and shaped into coils, sheets, or plates.

To achieve the desired dimensions and surface finish, the hot-rolled stainless steel undergoes cold rolling. It is passed through multiple rollers to reduce thickness, improve surface quality, and enhance mechanical properties.

The cold-rolled stainless steel is subjected to annealing, a heat treatment process that eliminates internal stresses and restores ductility. It is then pickled in an acid bath to remove any surface scale or impurities.

Depending on the intended application, the stainless steel may undergo additional processes such as polishing, coating, or surface treatment to enhance its appearance and corrosion resistance.

Conclusion: The production of stainless steel is a complex and fascinating process, involving the selection of raw materials, steelmaking, refining, and various shaping and finishing techniques. Understanding the meticulous steps involved in stainless steel production provides insight into the quality, properties, and versatility of this remarkable material. From architectural structures to household appliances, stainless steel continues to shape our modern world with its exceptional attributes.

Stainless steel is renowned for its exceptional resistance to corrosion, making it a preferred material in various industries. In this informative guide, we will delve into the scientific aspects of stainless steel’s anti-corrosion performance. From its unique composition to the protective oxide layer, we will explore the factors that contribute to stainless steel’s remarkable ability to withstand corrosion.

Stainless steel derives its corrosion resistance from its specific composition. It primarily consists of iron, chromium, and varying amounts of other alloying elements such as nickel, molybdenum, and titanium. The presence of chromium is crucial as it forms a protective layer on the surface of the steel, inhibiting corrosion.

The key to stainless steel’s resistance to corrosion lies in the formation of a passive oxide layer. When exposed to oxygen, the chromium in stainless steel reacts with it to form a thin, transparent, and self-repairing chromium oxide layer. This oxide layer acts as a barrier, preventing further interaction between the metal and corrosive agents.316 stainless steel is the better.

One remarkable characteristic of stainless steel is its ability to self-heal. If the oxide layer is damaged or scratched, the exposed steel immediately reacts with oxygen to regenerate the protective chromium oxide layer. This self-healing process ensures the continuous protection of the underlying steel and enhances the longevity of stainless steel in corrosive environments.

Stainless steel exhibits different levels of corrosion resistance depending on its alloy composition. Some common types of corrosion resistance observed in stainless steel include: General Corrosion Resistance: Stainless steel shows excellent resistance to uniform corrosion in a wide range of environments, including atmospheric conditions, fresh water, and mild chemical exposures. Pitting Corrosion Resistance: Stainless steel’s passive oxide layer provides remarkable resistance against pitting corrosion, which occurs as localized attack in the form of small pits or holes. This makes stainless steel suitable for applications in chloride-rich environments such as marine environments and swimming pools. Crevice Corrosion Resistance: Stainless steel resists crevice corrosion, which occurs in confined spaces or crevices where stagnant solutions can develop. The self-healing ability of stainless steel helps prevent the initiation and propagation of crevice corrosion.

While stainless steel offers impressive corrosion resistance, its performance can be influenced by environmental factors. Factors such as temperature, pH levels, and the presence of aggressive chemicals can affect the corrosion resistance of stainless steel. Understanding these factors is essential in selecting the appropriate stainless steel grade for specific applications.

Conclusion: Stainless steel’s anti-corrosion performance is a result of its unique composition, the formation of a passive oxide layer, and its self-healing capabilities. The ability of stainless steel to resist general corrosion, pitting corrosion, and crevice corrosion makes it a reliable and durable material for a wide range of applications. Whether in architectural structures, industrial equipment, or household appliances, stainless steel’s exceptional anti-corrosion properties contribute to its longevity and versatility.

Stainless steel is not only admired for its corrosion resistance but also for its remarkable ability to withstand high temperatures. In this comprehensive guide, we will explore the heat resistance of stainless steel, delving into its composition, alloying elements, and specific grades that excel in elevated temperature environments. Join us as we uncover the scientific aspects of stainless steel’s heat resistance.

Stainless steel is primarily composed of iron, chromium, and other alloying elements such as nickel, molybdenum, and titanium. These alloying elements play a vital role in enhancing the heat resistance of stainless steel. Chromium, in particular, forms a protective oxide layer on the surface, which helps withstand high temperatures.

Stainless steel demonstrates excellent oxidation resistance, allowing it to maintain its structural integrity even at elevated temperatures. The protective oxide layer formed by chromium prevents the underlying steel from reacting with oxygen, effectively preventing oxidation and scaling.

Certain stainless steel grades exhibit exceptional heat resistance, making them suitable for various applications in high-temperature environments. These grades include:

Austenitic Stainless Steels: Austenitic stainless steels, such as grades 304 and 316, are widely known for their excellent heat resistance. They can withstand temperatures up to 900-925°C (1650-1700°F) without significant deformation or loss of mechanical properties.

Ferritic Stainless Steels: Ferritic stainless steels, like grade 430, offer good heat resistance and maintain their strength at elevated temperatures. They are commonly used in applications requiring heat resistance up to 815°C (1500°F).

Heat-Resistant Stainless Steels: Specialized heat-resistant stainless steel grades, such as 309, 310, and 253MA, are specifically designed to withstand extreme temperatures. These alloys can operate in temperatures exceeding 1000°C (1830°F) and exhibit excellent resistance to thermal fatigue and creep.

The heat resistance of stainless steel finds applications in various industries, including:

Automotive Industry: Heat-resistant stainless steel is used in exhaust systems, catalytic converters, and engine components that operate at high temperatures.

Power Generation: Stainless steel is employed in power plants, nuclear reactors, and gas turbines, where components are subjected to extreme heat and thermal cycling.

Furnace and Heat Exchangers: Heat-resistant stainless steel is utilized in the construction of furnaces, heat exchangers, and boilers, ensuring optimal performance under high-temperature conditions.

When selecting stainless steel for high-temperature applications, factors such as the desired operating temperature, mechanical strength requirements, corrosion resistance, and thermal expansion properties must be carefully considered. Choosing the appropriate grade and alloy combination ensures optimal performance and longevity in challenging heat environments.

Conclusion: Stainless steel’s heat resistance stems from its unique composition and the formation of a protective oxide layer. Its ability to withstand high temperatures without significant deformation or loss of mechanical properties makes it a versatile material for a wide range of applications. By understanding the different stainless steel grades and their heat-resistant properties, industries can select the most suitable alloy to meet their specific high-temperature requirements.

Stainless steel is renowned for its exceptional durability and resistance to various environmental conditions. In this informative article, we will delve into the scientific aspects of stainless steel’s durability, examining its performance in different environments. Join us as we unravel the secrets behind stainless steel’s remarkable resilience.

One of the primary factors contributing to stainless steel’s durability is its remarkable corrosion resistance. The presence of chromium in stainless steel forms a passive oxide layer on the surface, protecting it from corrosion caused by moisture, chemicals, and other corrosive substances. This inherent corrosion resistance makes stainless steel highly durable in environments where other metals may deteriorate.

Stainless steel exhibits exceptional durability in atmospheric environments. It can withstand exposure to moisture, oxygen, and pollutants present in the air without significant degradation. This makes it an ideal choice for outdoor structures, architectural applications, and transportation industries where long-term durability is crucial.

Stainless steel is widely used in marine environments due to its excellent resistance to corrosion from seawater and salt air. It retains its durability and structural integrity even when exposed to the harsh conditions of the marine environment. This makes it an invaluable material for marine vessels, offshore platforms, and coastal infrastructure.

Stainless steel exhibits excellent durability in high-temperature environments. It retains its strength, mechanical properties, and corrosion resistance even at elevated temperatures. This makes it suitable for applications in heat exchangers, furnaces, and power generation plants where exposure to extreme heat is a constant factor.

Stainless steel’s durability and hygienic properties make it a staple material in the food and beverage industry. It is resistant to corrosion from food acids, maintains its cleanliness, and does not impart any undesirable flavors or contaminants. Stainless steel tanks, pipes, and equipment ensure the integrity and safety of food and beverage production processes.

Stainless steel exhibits exceptional durability in atmospheric environments. It can withstand exposure to moisture, oxygen, and pollutants present in the air without significant degradation. This makes it an ideal choice for outdoor structures, architectural applications, and transportation industries where long-term durability is crucial.

Conclusion:

Stainless steel’s exceptional durability stems from its inherent corrosion resistance and versatile performance in various environments. Its ability to withstand corrosion, atmospheric conditions, marine environments, chemical exposures, high temperatures, and demanding industrial settings make it a preferred material choice across diverse industries. Understanding stainless steel’s durability characteristics and adopting appropriate maintenance practices ensures its long-lasting performance and value.

Stainless steel is known for its corrosion-resistant properties, but in certain applications, it may benefit from an additional layer of protection against moisture and water. In this informative article, we will explore the science behind forming a waterproof layer on the surface of stainless steel. Join us as we uncover effective methods to enhance stainless steel’s resistance to water and moisture.

To Make stainless steel waterproof:Stainless steel naturally forms a passive oxide layer on its surface, which provides a level of protection against corrosion. This oxide layer acts as a barrier, preventing direct contact between the metal and the surrounding environment. However, it does not provide complete waterproofing, especially in prolonged exposure to water.

To Make stainless steel waterproof:One effective method to create a waterproof layer on stainless steel is by applying polymer coatings. These coatings are specially formulated to adhere to the metal surface and create a protective barrier against water infiltration. Polymer coatings can be applied through various techniques such as spraying, dipping, or electrostatic deposition, ensuring uniform coverage and adhesion.

To Make stainless steel waterproof:Another approach to forming a waterproof layer is through the use of conversion coatings. These coatings chemically react with the stainless steel surface, converting the metal oxide layer into a more hydrophobic and corrosion-resistant compound. Common conversion coatings include chromate, phosphate, and oxide-based coatings. They not only enhance waterproofing but also provide additional corrosion protection.

To Make stainless steel waterproof:Advancements in nanotechnology have introduced nano coatings that offer exceptional waterproofing properties. These coatings utilize nano-sized particles to create a superhydrophobic surface on stainless steel. The nano particles create a rough texture, which repels water droplets and prevents them from adhering to the surface. Nano coatings provide long-lasting waterproofing and can withstand harsh environmental conditions.

To Make stainless steel waterproof:Electrochemical treatments such as passivation can also be employed to enhance stainless steel’s waterproofing capabilities. Passivation involves immersing the stainless steel in an acid solution, which removes surface contaminants and enhances the formation of the passive oxide layer. This process improves the stainless steel’s resistance to corrosion and water penetration.

To Make stainless steel waterproof:To maintain the waterproof layer on stainless steel, regular cleaning and maintenance are essential. Avoid using abrasive cleaners or steel wool that can damage the protective coating. Instead, use mild detergents and soft cloths to clean the surface. Regular inspection for any signs of damage or wear and prompt repair or reapplication of coatings will ensure continued waterproofing effectiveness.

Conclusion:

Creating a waterproof layer on the surface of stainless steel enhances its resistance to water and moisture, providing additional protection against corrosion. Polymer coatings, conversion coatings, nano coatings, and electrochemical treatments offer effective methods to achieve this. Proper maintenance and regular inspections are crucial for maintaining the integrity of the waterproof layer. By employing these techniques, stainless steel can be effectively shielded from water-related damage, prolonging its lifespan and preserving its functionality.

Stainless steel is renowned for its exceptional strength and hardness, making it a versatile material used in various industries. In this informative article, we delve into the scientific aspects of stainless steel’s strength and hardness. Join us as we explore the factors that contribute to its robustness and understand why stainless steel is highly regarded for its mechanical properties.

The strength and hardness of stainless steel are influenced by its alloy composition. The primary components include iron, chromium, and varying amounts of other elements such as nickel, molybdenum, and manganese. The addition of these alloying elements enhances the material’s mechanical properties, including strength and hardness.

Austenitic stainless steel, such as the popular 304 and 316 grades, exhibits excellent strength and hardness. The presence of nickel and chromium in austenitic stainless steel significantly contributes to its strength and makes it resistant to corrosion. These alloys also provide superior toughness, allowing stainless steel to withstand high-stress applications.

Martensitic stainless steel is known for its high strength and hardness. It contains higher levels of carbon, which enables it to undergo a heat treatment process called quenching and tempering. This process transforms the microstructure, resulting in a martensitic structure that exhibits exceptional hardness and strength. Martensitic stainless steel is commonly used in applications where wear resistance and durability are essential.

Duplex stainless steel combines the properties of austenitic and ferritic stainless steels. It offers a balance between strength and corrosion resistance. The unique microstructure of duplex stainless steel provides higher strength compared to austenitic stainless steel, making it suitable for demanding environments such as marine and offshore applications.

Various methods are used to measure the hardness of stainless steel. The most commonly employed technique is the Rockwell hardness test, which involves indenting the material using a diamond cone or steel ball and measuring the depth of penetration. Other tests, such as Brinell and Vickers hardness tests, are also used depending on the specific requirements and characteristics of the stainless steel.

Apart from alloy composition, several factors affect the strength and hardness of stainless steel. These include grain size, heat treatment processes, cold working or deformation, and the presence of impurities. The careful control of these factors during manufacturing and processing ensures the desired mechanical properties of stainless steel.

Conclusion:

Stainless steel exhibits remarkable strength and hardness due to its alloy composition and specific manufacturing processes. Austenitic, martensitic, and duplex stainless steels offer varying levels of strength and hardness to suit different applications. Understanding the scientific aspects of stainless steel’s mechanical properties enables us to appreciate its widespread use in industries such as construction, automotive, aerospace, and more. With its robustness, stainless steel continues to be a preferred material, delivering both strength and durability for a multitude of applications.

In conclusion, stainless steel possesses inherent qualities that make it highly resistant to water and moisture. While stainless steel is not entirely waterproof, it exhibits remarkable resistance to corrosion and can withstand exposure to various environmental conditions, including humidity, rain, and even prolonged submersion in water. The passive oxide layer formed on its surface acts as a protective barrier, preventing water molecules from penetrating and causing damage.

The water-resistant nature of stainless steel makes it an excellent choice for applications where moisture is a concern. From kitchen appliances and bathroom fixtures to outdoor structures and marine equipment, stainless steel proves its worth by maintaining its integrity and appearance even in wet environments. Its ability to resist rust and staining ensures that it remains durable and aesthetically pleasing over time.

Additionally, the corrosion-resistant properties of stainless steel contribute to its longevity, reducing the need for frequent maintenance and replacement. This characteristic not only saves costs but also promotes sustainability by minimizing waste and resource consumption.

As a supplier of premium stainless steel products, we at Huaxiao Metal understand the importance of providing reliable and water-resistant materials to our customers. Our extensive range of stainless steel offerings, including sheets, coils, and tubes, undergo rigorous testing and meet industry standards to ensure superior performance and long-lasting durability in various environments.

Whether you require stainless steel for architectural projects, industrial applications, or consumer goods, our team of experts is committed to providing you with high-quality products that offer both functional excellence and aesthetic appeal. Contact us today to explore our comprehensive range of stainless steel solutions and discover how our products can meet your specific requirements.

In summary, while stainless steel is not completely waterproof, its exceptional resistance to corrosion and moisture makes it a reliable choice for a wide range of applications. With its longevity, durability, and aesthetic appeal, stainless steel continues to be a top choice for industries worldwide. Trust in the water-resistant properties of stainless steel and experience the benefits it brings to your projects.

Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours