Drilling through stainless steel requires the right tools, techniques, and precautions because stainless steel is a tough and durable material that resists deformation and heat. Here is a step-by-step guide on how to successfully drill through stainless steel:

So,How to drill through stainless steel?

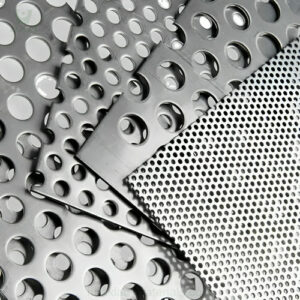

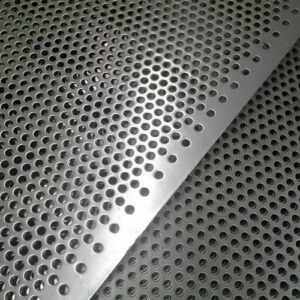

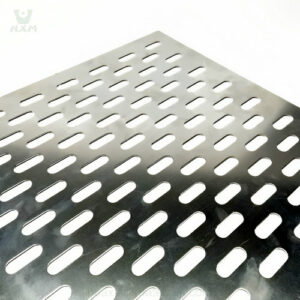

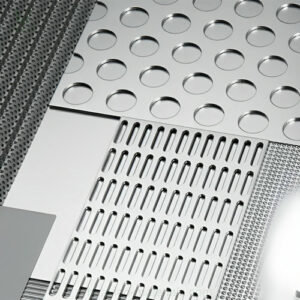

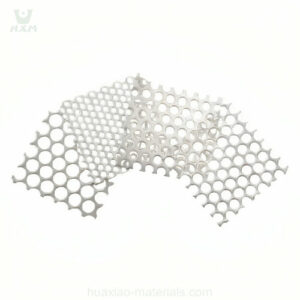

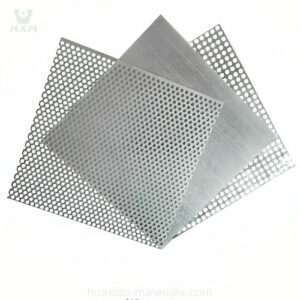

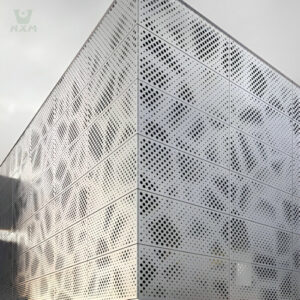

To make a stainless steel perforated plate, start by selecting the desired stainless steel material. Use specialized machinery to perforate the sheet, creating precise holes. The perforated plate is then shaped and finished according to specifications. Finally, inspect for quality and ensure the plate meets the intended application requirements.

This little story is interesting and brings up the common question of How to drill through stainless steel. While the problem may seem simple, in reality, it involves many complicated factors and technical details. In the following articles, we will delve deeper into these issues and answer these common but confusing questions for you.

Apply cutting oil or a lubricant directly to the drill bit and the drilling surface. This minimizes friction, prevents overheating, and extends the life of the drill bit. Reapply the fluid regularly as needed during drilling.

Heat buildup is a common issue when drilling stainless steel. To control heat:

| Challenge | Solution |

|---|---|

| Drill bit dulls quickly | Use cobalt or carbide bits, apply cutting fluid, and drill at a lower speed. |

| Bit slips on the surface | Use a center punch to create an indentation before drilling. |

| Overheating | Apply cutting fluid, reduce speed, and drill in intervals to allow cooling. |

| Rough hole edges | Deburr the hole using a file or deburring tool. |

Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours