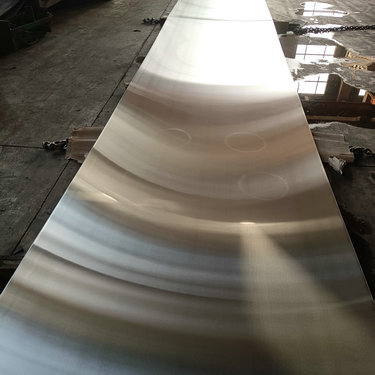

18 10 stainless steel sheet plates

18 10 STAINLESS STEEL PLATE SHEET The 18/10 stainless steel sheet plate is a high-quality alloy consisting of 18% chromium and 10% nickel.Corrosion-resistant alloy with high chromium and nickel content. Ideal for kitchenware, food processing, and architectural projects. Durable and visually appealing. 18 10 STAINLESS STEEL PLATE sheet Type Stainless Steel Sheet / Stainless Steel […]

Etched stainless steel sheet

Etched stainless steel sheet is created by selectively removing the surface material to create decorative patterns or designs.

Embossed stainless steel sheet

Embossed stainless steel sheets are produced using a mechanical or hydraulic press that creates raised or sunken patterns on the surface of stainless steel sheets. The process involves pressing the sheet between two dies to impart the desired design or texture onto the metal surface.

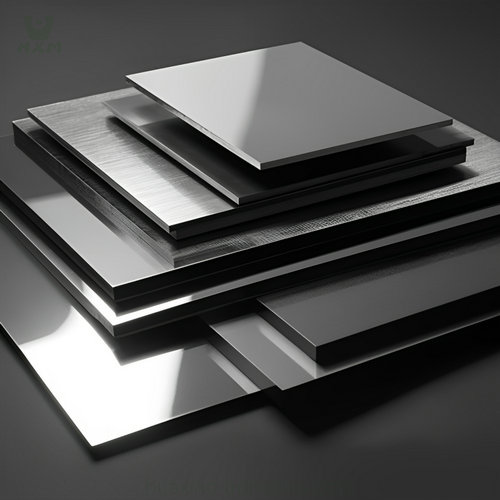

201 stainless steel

201 stainless steel is a type of austenitic stainless steel with excellent corrosion resistance and high tensile strength. It contains lower nickel content compared to other stainless steel grades, making it more affordable. Commonly used in kitchenware, appliances, and automotive components.

Stainless steel #4 finish

Stainless steel #4 finish is a smooth and brushed surface treatment commonly applied to stainless steel surfaces. It provides a clean and non-reflective appearance, making it ideal for decorative and architectural applications.

Cold rollled seamless stainless steel pipe

Cold-rolled seamless stainless steel pipes, available in various common grades such as 304, 316, and 321, are produced using a cold-rolling process. These pipes offer exceptional corrosion resistance, strength, and dimensional accuracy. They are widely used in industries like construction, petrochemical, and food processing for their superior performance and versatility.

How to polish stainless steel to a mirror finish?

To achieve a mirror finish on stainless steel, follow these steps: Clean the surface thoroughly. Apply a stainless steel polishing compound. Polish the surface using circular motions. Remove excess compound and clean the surface again. Optionally, apply a protective coating.

Mig welding stainless steel

MIG welding stainless steel, or Metal Inert Gas welding, is a widely used process for joining stainless steel components. It involves the use of a consumable wire electrode and a shielding gas to create an electric arc that melts and fuses the stainless steel pieces together. MIG welding offers excellent control, high welding speeds, and good weld quality. It is commonly used in various industries, including automotive, construction, and manufacturing, where stainless steel’s corrosion resistance and strength are essential. Proper equipment, technique, and knowledge of stainless steel properties are crucial for achieving durable and high-quality welds.

Is carbon steel better than stainless steel?

When considering stainless steel versus carbon steel, it’s important to understand their differences. Stainless steel is known for its corrosion resistance and durability, making it ideal for various applications. Stainless steel suppliers offer a wide range of products with different grades and finishes to meet specific needs. On the other hand, carbon steel is often chosen for its strength and affordability. However, it is more susceptible to corrosion and requires protective coatings. Ultimately, the choice between stainless steel and carbon steel depends on factors such as the intended use, budget, and environmental conditions. Consulting with reputable stainless steel suppliers can help determine the best material for your specific requirements.

How to drill through stainless steel?

Master the art of drilling through stainless steel with precision. Discover proven techniques, specialized tools, and expert guidance to achieve flawless results. Unlock the secrets of this challenging task and conquer stainless steel with confidence.