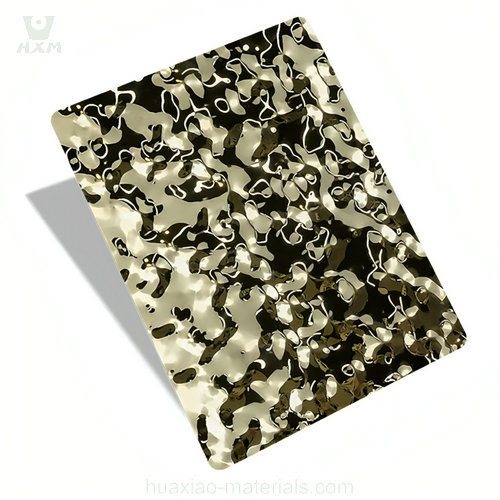

Dive into the World of Water Wave Stamped Stainless Steel Sheets, where artistry meets durability in a joyful dance! Let your imagination ride the waves of creativity as you explore the vibrant patterns that transform any space into a work of art. With these sheets, your designs will make a splash, captivating hearts with their playful charm. Crafted with precision and built to last, they bring both style and substance to your projects. Get ready to ride the wave of inspiration and create something extraordinary. Dive in and make a splash with Water Ripple Stainless Steel Sheet!

| Type | Water Wave Stamped Stainless Steel Sheets |

|---|---|

| Color | Silver, Gold, Rose Gold, Champagne, Bronze, Black, Blue, etc. |

| Thickness | 0.3mm – 3.0mm, and other options |

| Size | 10002000mm, 12192438mm, 1219*3048mm, custom maximum width up to 1500mm |

| Stainless Steel Grade | 304, 316, 201, 430, and other options |

| Finish | PVD Color + Stamped + Mirror Finish |

| Available Finishes | No.4, Hairline, Mirror, Etched, PVD Color, Embossed, Vibration, Sandblasting, Combination, Laminated, etc. |

| Steel Mills | POSCO, JISCO, TISCO, LISCO, Baosteel, and others |

| Packaging | PVC + Waterproof Paper + Sturdy Plywood Crate Packaging, packaging can be adjusted according to customer requirements |

Grade | STS304 | STS316 | STS430 | STS201 |

|---|---|---|---|---|

Elong (10%) | Above 40 | 30 min | Above 22 | 50-60 |

Hardness | ≤200HV | ≤200HV | Below 200 | HRB100, HV 230 |

Cr (%) | 18-20 | 16-18 | 16-18 | 16-18 |

Ni (%) | 8-10 | 10-14 | ≤0.60% | 0.5-1.5 |

C (%) | ≤0.08 | ≤0.07 | ≤0.12% | – |

Decorative stainless steel sheets are widely used in various industries for their aesthetic appeal and durability. One of the key factors that contribute to their visual impact is the choice of finishes. In this comprehensive guide, we will delve into the different finishes available for stainless steel decorative sheets. By understanding these finishes, you can select the most suitable option to achieve your desired aesthetic outcome. Let’s explore the various finishes in detail.

The No.4 finish, also known as brushed finish, features a smooth and satin-like appearance. It is achieved by using abrasive materials to create fine linear polishing lines on the stainless steel surface. This finish is popular for its elegant and contemporary look.

The mirror finish, as the name suggests, provides a highly reflective and mirror-like appearance. It involves extensive polishing to create a flawless, reflective surface. This finish adds a touch of sophistication and is often used in luxury architectural and interior design applications.

Etched finishes involve chemically treating the stainless steel surface to create intricate patterns or designs. This process selectively removes the surface layer, resulting in a textured and visually appealing finish. Etched finishes offer endless possibilities for customization and are commonly used in artistic and decorative applications.

PVD (Physical Vapor Deposition) color finishes involve depositing a thin layer of metal alloy onto the stainless steel surface through a vacuum coating process. This allows for a wide range of vibrant and durable color options, enhancing the visual impact of the sheets. PVD color finishes are popular in architectural and interior design, adding a pop of color to the decor.

Textured finishes provide a tactile and visually interesting surface. Various techniques, such as embossing or engraving, are used to create patterns, textures, or motifs on the stainless steel sheets. These finishes offer a unique and captivating appearance, making them suitable for artistic and decorative purposes.

Combination finishes combine different techniques to create contrasting textures and visual effects. For example, a combination of brushed and polished surfaces can be used to achieve a striking and multidimensional look. This type of finish offers versatility and allows for creative design possibilities.

Conclusion: The choice of finish greatly influences the aesthetic appeal and character of decorative stainless steel sheets. Whether you prefer a sleek and modern look with a mirror or No.4 finish, or desire a customized etched or PVD color finish, there are various options available to suit your specific design requirements. By understanding the different finishes and their characteristics, you can make informed decisions when selecting decorative stainless steel sheets, elevating the visual impact of your projects and creating stunning and distinctive spaces.

Water wave stamped stainless steel sheets are a popular choice for decorative applications due to their unique and eye-catching design. Understanding the manufacturing process behind these sheets can provide valuable insights into their quality and characteristics. In this comprehensive guide, we will explore the detailed process of manufacturing water wave stamped stainless steel sheets. Let’s dive into the intricacies of this fascinating process.

The manufacturing process begins with the careful selection of high-quality stainless steel sheets. The grade and composition of the stainless steel are crucial in determining the final product’s durability and aesthetic appeal. Stainless steel suppliers play a vital role in providing the appropriate stainless steel material for the manufacturing process.

A skilled team of designers creates the water wave pattern using computer-aided design (CAD) software. The pattern is meticulously developed, considering factors such as wave shape, size, and spacing to achieve the desired visual effect. The pattern design is a crucial step that determines the uniqueness and attractiveness of the final product.

The stamped pattern is created using specialized machinery and tools. The stainless steel sheet is placed on a stamping press, and a patterned die is pressed onto the surface with controlled force. This process forms the water wave design by displacing the material in a precise and controlled manner. Multiple stamping passes may be required to achieve the desired depth and clarity of the pattern.

After stamping, the water wave stamped stainless steel sheets undergo a heat treatment process. This process helps to relieve internal stresses and improve the material’s hardness and strength. Heat treatment also enhances the sheet’s dimensional stability, ensuring that it retains its shape and pattern during further processing and handling.

To enhance the aesthetic appeal and durability of the sheets, various surface finishing techniques are applied. These may include processes such as polishing, brushing, or coating. The chosen surface finish can significantly impact the visual appearance and texture of the water wave pattern, allowing for customization and differentiation.

Throughout the manufacturing process, strict quality control measures are implemented to ensure the production of high-quality water wave stamped stainless steel sheets. Comprehensive inspections are conducted to verify the accuracy of the pattern, detect any defects or imperfections, and ensure compliance with industry standards.

Conclusion: The manufacturing process of water wave stamped stainless steel sheets involves precise craftsmanship, advanced machinery, and attention to detail. From material selection to pattern design, stamping, heat treatment, surface finishing, and quality control, each step contributes to the creation of visually stunning and durable decorative stainless steel sheets. By understanding the intricacies of the manufacturing process, customers can make informed decisions when selecting water wave stamped stainless steel sheets, ensuring they receive high-quality products that add a touch of elegance and uniqueness to their projects.

Decorative stainless steel sheets have gained popularity as a versatile and visually appealing option for various decorative applications. Understanding the advantages they offer can help you make an informed decision when considering them for your decorative projects. In this comprehensive guide, we will explore the numerous benefits of using decorative stainless steel sheets, highlighting their unique properties and applications. Let’s delve into the world of decorative stainless steel and discover why it is an excellent choice for enhancing aesthetics.

Decorative stainless steel sheets are available in a wide range of finishes, patterns, and colors, allowing for endless design possibilities. Whether you prefer a sleek and modern look or a more traditional and ornate style, stainless steel decorative sheets offer a versatile canvas to bring your creative visions to life. The reflective surfaces and unique textures of these sheets add depth and dimension to any space, creating a visually striking impact.

One of the key advantages of decorative stainless steel sheets is their exceptional durability. Stainless steel is highly resistant to corrosion, stains, and scratches, making it ideal for both indoor and outdoor applications. The sheets are designed to withstand harsh environmental conditions, ensuring that they retain their beauty and functionality for years to come. Additionally, stainless steel decorative sheets are easy to clean and maintain, reducing the need for frequent repairs or replacements.

Stainless steel decorative sheets offer remarkable versatility, making them suitable for a wide range of decorative purposes. They can be used for wall cladding, room dividers, ceilings, furniture accents, signage, and more. With advanced manufacturing techniques, these sheets can be customized in terms of size, shape, patterns, and finishes, allowing for tailored solutions that meet specific design requirements. Stainless steel suppliers play a crucial role in providing customized solutions and expertise in material selection.

In environments where hygiene is paramount, such as healthcare facilities, food processing areas, and clean rooms, decorative stainless steel sheets offer significant advantages. Stainless steel is non-porous, making it resistant to bacterial growth and easy to sanitize. It also does not release harmful chemicals, ensuring a safe and healthy environment. These properties make stainless steel sheets suitable for applications where cleanliness and safety are crucial considerations.

Decorative stainless steel sheets are an environmentally friendly choice. Stainless steel is a recyclable material, and the manufacturing process involves minimal waste generation. By opting for stainless steel decorative sheets, you contribute to sustainable practices and reduce the overall environmental impact.

Choosing a reputable stainless steel supplier is essential to ensure the quality and reliability of decorative stainless steel sheets. Trusted suppliers offer technical expertise, comprehensive customer support, and a wide range of options to meet your specific project requirements. Collaborating with a reliable supplier ensures that you receive high-quality materials and valuable guidance throughout the design and installation process.

Conclusion: The advantages of using decorative stainless steel sheets for decorative purposes are undeniable. With their aesthetic appeal, durability, versatility, hygiene properties, and sustainability, stainless steel decorative sheets offer a compelling choice for enhancing the visual appeal of various spaces. When coupled with the expertise and support of reputable stainless steel suppliers, you can confidently embark on your decorative projects, knowing that you are investing in a long-lasting and visually captivating solution.

Decorative stainless steel sheets have revolutionized the world of architecture and design, offering endless possibilities for creating visually stunning and functional spaces. With their unique properties and versatility, these sheets have become a preferred choice for architects, interior designers, and builders. In this comprehensive guide, we will explore the popular applications of decorative stainless steel sheets in architecture and design, highlighting their transformative impact on various projects. Let’s delve into the world of stainless steel decorative sheets and discover their wide range of uses.

Decorative stainless steel sheets are widely used for wall cladding in both interior and exterior applications. Their reflective surfaces and intricate patterns add a sense of elegance and sophistication to any space. Whether it’s a commercial building, residential property, or public facility, stainless steel decorative sheets enhance the aesthetics and create a striking visual impact.

Stainless steel decorative sheets are also used for ceilings and suspended panels, offering a contemporary and luxurious look. The reflective qualities of stainless steel bring depth and dimension to the space, while the decorative patterns and finishes add a touch of uniqueness. This application is commonly seen in hotels, restaurants, shopping malls, and high-end residential properties.

To create focal points and add architectural interest, decorative stainless steel sheets are employed for column cladding and feature walls. The distinctive patterns and textures of these sheets help transform plain structures into visually captivating elements. Whether it’s a standalone column or a designated feature wall, stainless steel decorative sheets provide a striking visual element that enhances the overall design.

Stainless steel decorative sheets are a popular choice for elevator interiors, adding a touch of luxury and elegance to this functional space. The reflective surfaces of the sheets create an illusion of spaciousness, while the decorative patterns and finishes enhance the interior aesthetics. Elevators in high-end residential buildings, hotels, and commercial spaces often feature stainless steel decorative sheets to elevate the user experience.

From furniture accents to light fixtures and railings, decorative stainless steel sheets are utilized to create unique design elements. The versatility of stainless steel allows for intricate shapes, curves, and custom designs, enabling architects and designers to incorporate decorative accents seamlessly. These sheets can be transformed into intricate screens, partitions, and decorative grilles, adding a touch of elegance and functionality to various architectural features.

Stainless steel decorative sheets are an excellent choice for signage and branding purposes. The durable and weather-resistant nature of stainless steel ensures that the signage remains visually appealing and intact over time. The reflective surfaces of these sheets enhance visibility, making the signage stand out and effectively represent the brand image.

In modern architecture, stainless steel decorative sheets are increasingly used for exterior facades. Their durability, weather resistance, and design versatility make them ideal for creating eye-catching facades that blend seamlessly with the surrounding environment. These sheets can be customized to meet specific design requirements, offering architects and designers the freedom to create stunning and innovative exteriors.

Conclusion: The applications of decorative stainless steel sheets in architecture and design are vast and diverse. From wall cladding and ceilings to column cladding, elevators, and decorative accents, these sheets bring beauty, durability, and functionality to a wide range of projects. With their ability to transform spaces and create visually captivating elements, stainless steel decorative sheets continue to be a popular choice for architects, interior designers, and builders seeking to elevate the aesthetics of their designs. By partnering with reputable stainless steel suppliers, professionals can access a wide range of options and expertise to bring their architectural visions to life.

Water wave stamped stainless steel sheets are a popular choice for architectural and design applications due to their unique and visually appealing design patterns. These sheets offer a perfect blend of aesthetics, functionality, and durability, making them ideal for a wide range of projects. In this comprehensive guide, we will explore the design patterns of water wave stamped stainless steel sheets, providing a detailed and scientifically accurate analysis of their characteristics, applications, and advantages. Let’s dive into the world of water wave stamped stainless steel sheets and discover the intricacies of their design patterns.

Water wave stamped stainless steel sheets feature a distinctive wavy pattern that resembles gentle water ripples. The manufacturing process involves precision stamping techniques that create the intricate wave design on the stainless steel surface. This process ensures consistency and precision in the pattern, resulting in visually appealing and high-quality sheets.

The design pattern of water wave stamped stainless steel sheets is characterized by undulating lines that mimic the movement of water waves. The waves vary in size, depth, and spacing, creating a dynamic and visually engaging pattern. The design captures light in unique ways, resulting in a play of reflections and shadows that add depth and dimension to the surface.

Water wave stamped stainless steel sheets are available in various surface finishes, further enhancing their design appeal. Common finishes include polished, brushed, and etched surfaces. The choice of finish can significantly impact the overall aesthetics and visual impact of the design pattern, allowing for customization to suit different design styles and preferences.

The design pattern of water wave stamped stainless steel sheets lends itself to a wide range of applications in architecture and design. These sheets are commonly used for wall cladding, decorative ceilings, column cladding, furniture accents, and interior accents. The captivating design pattern adds a touch of elegance and sophistication to any space, making it a preferred choice for high-end residential, commercial, and hospitality projects.

The design pattern of water wave stamped stainless steel sheets offers several advantages. Firstly, it creates a visually striking and unique feature that stands out in any environment. Secondly, the stainless steel material provides excellent durability, corrosion resistance, and ease of maintenance. Additionally, the design pattern can help mask minor surface imperfections, enhancing the overall appearance of the sheet.

Water wave stamped stainless steel sheets can be customized to meet specific design requirements. Designers can choose from various wave sizes, depths, and spacing options to create a tailored pattern that complements the project’s aesthetics. This level of customization allows for endless creative possibilities, ensuring that the design perfectly aligns with the vision and concept of the space.

Conclusion: The design pattern of water wave stamped stainless steel sheets offers a captivating and visually appealing option for architectural and design applications. With their undulating lines and dynamic wave patterns, these sheets add a touch of elegance and sophistication to any space. The versatility, durability, and customization options make water wave stamped stainless steel sheets a preferred choice for designers, architects, and builders. By collaborating with reputable stainless steel suppliers, professionals can access a wide range of design options and expertise to bring their creative visions to life.

When it comes to sourcing water wave stamped stainless steel sheets, finding reliable suppliers is crucial to ensure the quality, timely delivery, and competitive pricing. This guide aims to provide you with a scientifically accurate and detailed analysis of where to find trustworthy suppliers of water wave stamped stainless steel sheets. We will explore the key factors to consider, the qualities of reliable suppliers, and provide practical tips to facilitate your search. Let’s dive into the world of stainless steel suppliers and discover the best sources for water wave stamped stainless steel sheets.

Reliable suppliers of water wave stamped stainless steel sheets possess extensive industry knowledge and experience. They understand the technical aspects of stainless steel manufacturing, including the stamping process and quality control measures. Look for suppliers with a proven track record in the industry, as they are more likely to provide high-quality products and professional services.

Ensure that the suppliers you consider comply with industry standards and hold relevant certifications. Look for suppliers who adhere to international quality management systems, such as ISO 9001, to ensure consistency and reliability in their products. Certifications and adherence to standards demonstrate a commitment to quality and provide reassurance to customers.

Consider suppliers who offer a diverse range of water wave stamped stainless steel sheets to meet your specific needs. They should provide various thicknesses, sizes, and finishes to accommodate different project requirements. Additionally, reliable suppliers should have the capability to offer customization options, allowing you to tailor the sheets to your desired specifications.

Reliable suppliers prioritize quality assurance throughout the manufacturing process. They implement stringent quality control measures to ensure that the water wave stamped stainless steel sheets meet or exceed industry standards. Look for suppliers who conduct thorough inspections, perform material testing, and provide certifications of compliance to ensure the quality and durability of the products.

Efficient supply chain management is crucial when selecting suppliers. Reliable suppliers have well-established relationships with steel mills and other stakeholders in the supply chain, ensuring a consistent and timely flow of materials. They should have the capacity to meet your project’s requirements and deliver the water wave stamped stainless steel sheets within the agreed-upon timelines.

Consider suppliers who prioritize excellent customer service and support. They should have knowledgeable and responsive sales representatives who can assist you with inquiries, provide technical guidance, and offer solutions to any challenges that may arise. Suppliers who value long-term partnerships will go the extra mile to ensure customer satisfaction and address any concerns promptly.

Conclusion: Finding reliable suppliers of water wave stamped stainless steel sheets requires careful consideration of various factors. By selecting suppliers with industry knowledge, certifications, diverse product ranges, and a commitment to quality, you can ensure the procurement of high-quality materials for your projects. Remember to assess their supply chain capabilities, customer service, and support to ensure a smooth and successful collaboration. By partnering with trustworthy stainless steel suppliers, you can have confidence in the quality, reliability, and timely delivery of water wave stamped stainless steel sheets for your decorative needs.

Water wave stamped stainless steel sheets offer a unique and visually appealing solution for decorative purposes. Throughout this comprehensive exploration, we have answered several key questions related to these sheets, providing a scientific and detailed understanding of their manufacturing process, design patterns, applications, advantages, and reliable suppliers.

In summary, the different finishes available for decorative stainless steel sheets include No.4, hairline, mirror, etching, PVD color, embossing, vibration, sandblasting, combination, and laminating. These finishes add versatility and aesthetic appeal to architectural and design projects.

The process of manufacturing water wave stamped stainless steel sheets involves several steps, including material selection, stamping, coloring with PVD technology, and achieving a mirror finish. Each stage contributes to the final product’s durability, visual appeal, and unique wave-like design.

The advantages of using decorative stainless steel sheets for decorative purposes are numerous. These sheets offer excellent corrosion resistance, durability, versatility in design, ease of maintenance, and a wide range of available colors and finishes. They can enhance the visual appeal of various interior and exterior applications, including walls, ceilings, furniture, and more.

Water wave stamped stainless steel sheets come in various design patterns, resembling gentle waves that add a dynamic and captivating element to any space. These patterns are achieved through precise stamping techniques that create a three-dimensional effect, resulting in a visually striking appearance.

When it comes to sourcing reliable suppliers of water wave stamped stainless steel sheets, certain factors should be considered. Look for suppliers with industry knowledge and experience, certifications, a diverse product range, quality assurance measures, efficient supply chain management, and excellent customer service and support.

In conclusion, water wave stamped stainless steel sheets offer an excellent choice for decorative purposes, providing both functionality and aesthetic appeal. Their unique design patterns, wide range of finishes, and durability make them suitable for various architectural and design applications. By partnering with reliable suppliers, customers can ensure the procurement of high-quality materials that meet their specific project requirements.

Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours