18-8 stainless steel vs 316 stainless steel

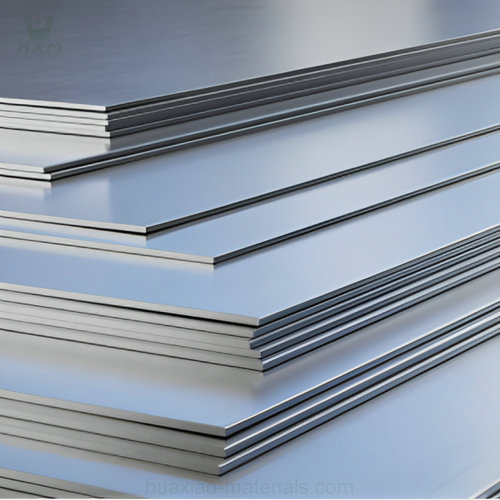

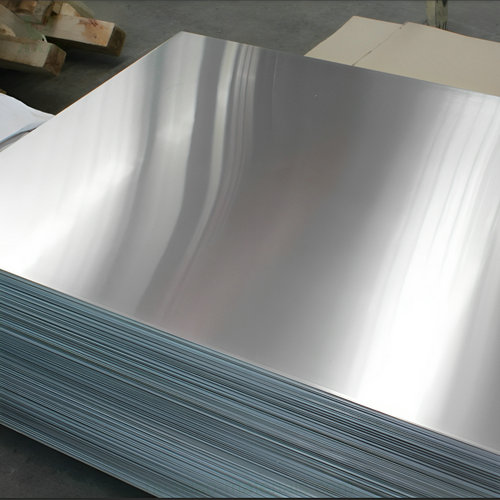

Stainless steel, a versatile alloy celebrated for its corrosion resistance and durability, comes in various grades, each tailored to specific applications and environments. Among the myriad options, 18-8 stainless steel and 316 stainless steel stand out as widely used alloys, each with its unique set of properties and applications.