When selecting suppliers for 301 stainless steel products, there are several important factors to consider to ensure you receive high-quality materials and services. Here are some key considerations:

Quality and Certification: Choose suppliers that offer products that meet recognized quality standards and certifications, such as ASTM, ISO, or other industry-specific standards. Make sure they can provide documentation to prove the quality and authenticity of their materials.

Experience and Reputation: Look for suppliers with a solid track record and reputation in providing stainless steel products. An established supplier with years of experience is more likely to offer reliable products and services.

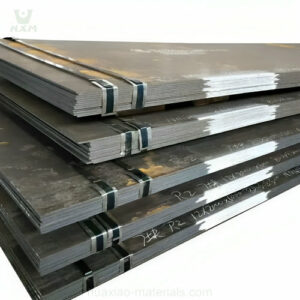

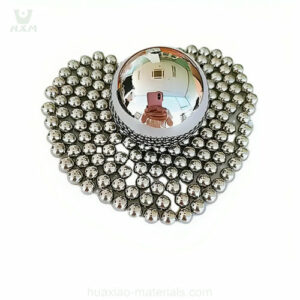

Material Variety and Availability: Ensure the supplier offers a range of 301 stainless steel products in different forms, sizes, and finishes to meet your specific requirements. Availability of stock is crucial to avoid delays in your projects.

Customization: If your application requires custom sizes, shapes, or finishes, choose a supplier that offers customization services to match your needs.

Technical Expertise: A supplier with technical expertise can provide valuable guidance on material selection, fabrication processes, and more. They can help you make informed decisions about using 301 stainless steel for your specific application.

Delivery and Lead Times: Timely delivery is essential for your projects. Choose a supplier that can reliably meet your delivery requirements and has a history of on-time deliveries.

Customer Support: Consider the level of customer support the supplier offers. Prompt communication, responsiveness to inquiries, and willingness to address your concerns are crucial for a smooth procurement process.

Quality Assurance: Inquire about the supplier’s quality control practices. Do they inspect their materials before shipping? Are they committed to providing materials that meet specified standards?

Price and Payment Terms: While cost is an important factor, it’s not the only one. Look for a balance between competitive pricing and the quality of materials and services. Also, discuss payment terms that align with your budget and financial planning.

Location and Shipping: If your project has specific shipping requirements, consider the supplier’s location and their ability to ship to your desired destination.

References and Reviews: Seek references or read reviews from other customers who have worked with the supplier. Their feedback can provide insights into the supplier’s reliability and performance.

Environmental Considerations: If environmental responsibility is important to your organization, inquire about the supplier’s sustainability practices and whether their products meet environmental regulations.

Long-Term Relationship: Consider the potential for a long-term partnership. A supplier that understands your needs and can grow with your business can offer stability and consistency.

Samples and Testing: If possible, request samples or perform testing to verify the quality and suitability of the supplier’s 301 stainless steel products for your application.

By carefully evaluating these factors and conducting thorough research, you can select a reputable supplier that not only provides high-quality 301 stainless steel products but also offers reliable services and support throughout your projects.