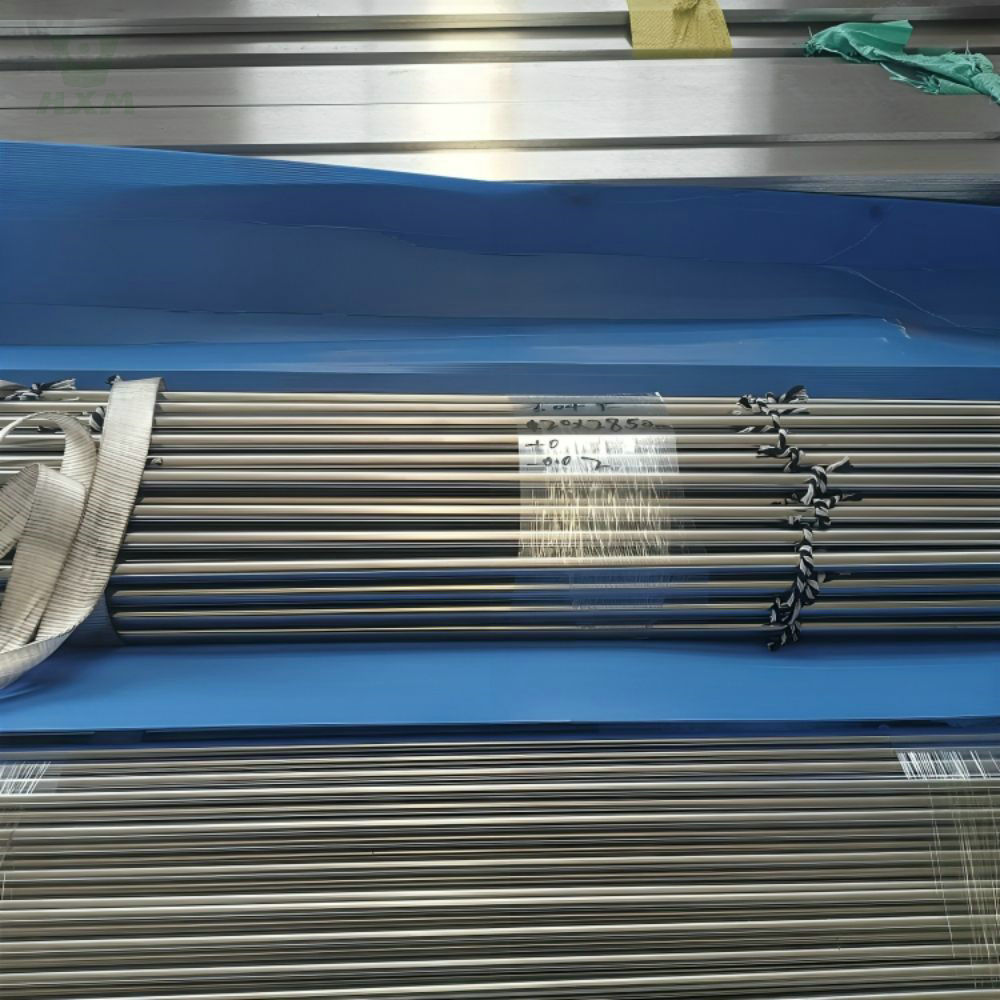

304 stainless steel round bars are popular in various industries and applications due to their excellent combination of key properties, making them highly versatile and widely used. The key properties that contribute to the popularity of 304 stainless steel round bars include:

Corrosion Resistance: 304 stainless steel exhibits outstanding corrosion resistance, particularly in acidic, chloride-rich, and marine environments. This property is critical for applications exposed to moisture, chemicals, or corrosive substances.

Strength: 304 stainless steel has good tensile and yield strength, providing structural integrity and load-bearing capabilities in a wide range of applications.

Formability: It is easily formable and can be fabricated into various shapes and sizes, making it suitable for complex designs and custom components.

Weldability: 304 stainless steel is easily weldable, allowing for the creation of strong, seamless joints and assemblies. This property simplifies manufacturing processes.

Machinability: It offers good machinability, enabling efficient and precise machining of components, such as threads, holes, and precision parts.

Hygienic Properties: 304 stainless steel is non-reactive and non-toxic, making it suitable for food processing, medical, and pharmaceutical applications where hygiene and safety are paramount.

Temperature Resistance: It maintains its properties at both low and high temperatures, making it suitable for a wide range of operating conditions.

Aesthetic Appeal: The material has a bright, polished finish that enhances its visual appeal, making it suitable for architectural and decorative applications.

Low Maintenance: 304 stainless steel is easy to clean and maintain, reducing the need for frequent upkeep and extending the lifespan of components.

Wide Range of Applications: Due to its versatile properties, 304 stainless steel is used in a diverse range of industries, including construction, automotive, aerospace, chemical processing, food and beverage, healthcare, and more.

Longevity: It offers excellent durability and a long service life, reducing replacement and maintenance costs over time.

Recyclability: Stainless steel, including 304, is highly recyclable, contributing to environmental sustainability and reducing the demand for new raw materials.

These properties collectively make 304 stainless steel round bars a preferred choice for applications where corrosion resistance, strength, formability, and overall performance are critical. Its suitability for both indoor and outdoor use, along with its aesthetic appeal, further enhances its popularity in various industries.