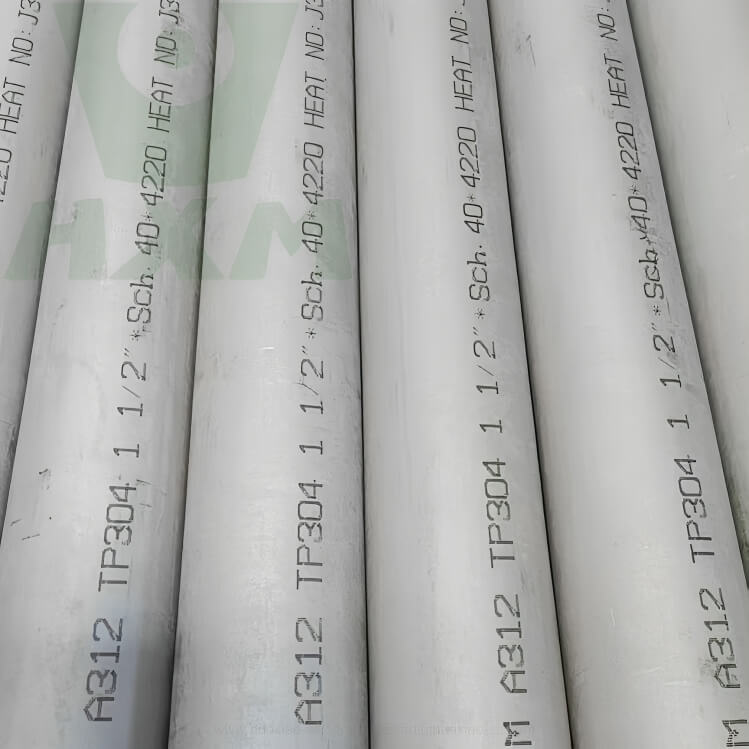

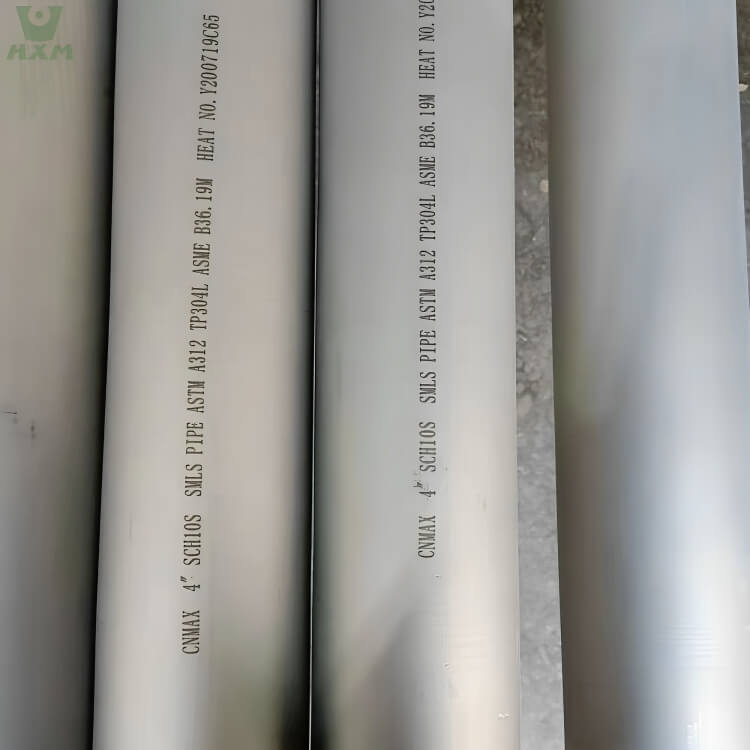

304 stainless steel seamless pipes find wide-ranging applications across various industries due to their excellent corrosion resistance, durability, and versatility. Some common industries and applications include:

Oil and Gas: Used for transporting oil, gas, and other petrochemical fluids in pipelines and refineries. Its corrosion resistance is crucial in these harsh environments.

Chemical Processing: Suitable for conveying various chemicals and corrosive substances, 304 stainless steel seamless pipes are used in chemical plants and manufacturing processes.

Food and Beverage: Because of its hygienic properties and resistance to food acids and liquids, it is commonly used in food processing, dairy, breweries, and the production of pharmaceuticals.

Pharmaceuticals: 304 stainless steel seamless pipes are vital for the pharmaceutical industry, where product purity and hygiene standards are critical.

Water Treatment: These pipes are used in water treatment plants, desalination facilities, and wastewater management due to their resistance to corrosion and chemical exposure.

Automotive: Applications include exhaust systems, structural components, and fuel delivery systems due to their durability and corrosion resistance.

Aerospace: Used in aircraft components and systems where lightweight and corrosion-resistant materials are essential.

Construction: Commonly used in architectural structures, balustrades, handrails, and building frameworks due to its aesthetic appeal and corrosion resistance.

Marine: In marine applications, 304 stainless steel seamless pipes are used for boat components, shipbuilding, and offshore oil and gas platforms due to their resistance to saltwater corrosion.

Medical: Used for medical gas delivery systems, hospital equipment, and surgical instruments because of its non-reactive and hygienic properties.

Automated Manufacturing: In industries that require high-precision equipment, such as semiconductor manufacturing, 304 stainless steel seamless pipes are used due to their cleanliness and resistance to contamination.

Power Generation: Used for conveying water, steam, and other fluids in power plants, where corrosion resistance and high-temperature tolerance are essential.

Renewable Energy: In applications like solar panel mounting systems, where resistance to environmental exposure is crucial.

Transportation: Used in the production of railings, bus shelters, and transportation equipment due to its durability and low maintenance requirements.

Environmental Engineering: For conveying wastewater, sewage, and chemicals in sewage treatment plants and environmental engineering projects.

Mining: In mining operations, these pipes are used for conveying various fluids and materials.

Industrial Machinery: In the manufacturing of industrial machinery and equipment, where corrosion resistance is needed to ensure long-term performance.

Telecommunications: In infrastructure applications, such as cell tower installations and cable management systems.

These are just a few examples of the many industries and applications where 304 stainless steel seamless pipes play a vital role due to their outstanding properties and performance.