18-8 stainless steel vs 316

18-8 stainless steel, known as Type 304, consists of 18% chromium and 8% nickel. On the other hand, 316 stainless steel has 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. While both offer corrosion resistance, 316 provides better resistance to chloride environments, making it suitable for marine and chemical applications.

Is stainless steel magnetic?

The magnetic properties of stainless steels vary depending on their composition and treatment. In general, austenitic stainless steels are usually non-magnetic, while martensitic stainless steels may be magnetic.

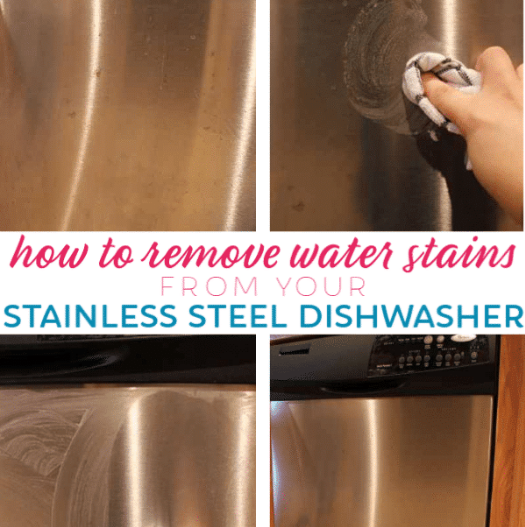

How to remove hard water stains from stainless steel?

To remove hard water stains from stainless steel, apply vinegar or lemon juice, gently scrub, then rinse and dry. Commercial cleaners or a baking soda paste can also be effective.

301 stainless steel

301 stainless steel is an austenitic alloy with 17% chromium and 7% nickel. It’s known for its high strength and excellent corrosion resistance. Used in various applications like springs, utensils, and automotive components.

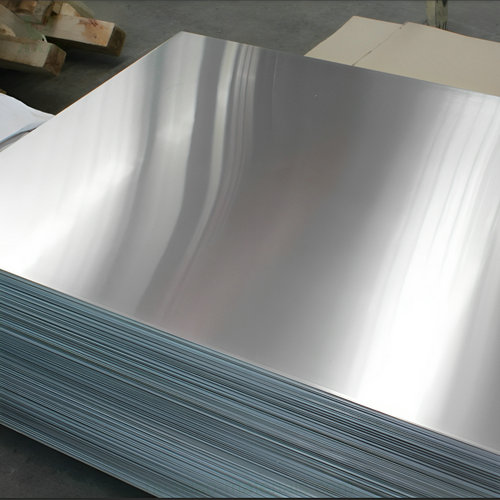

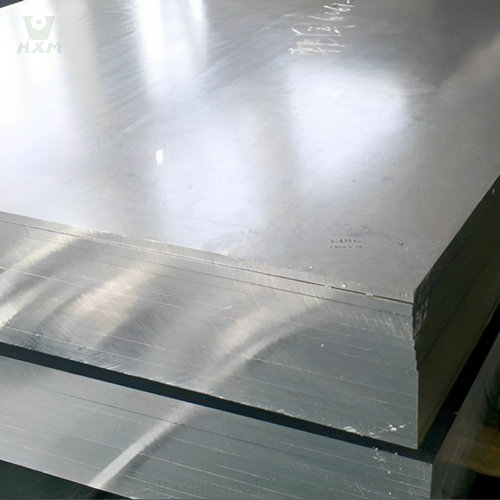

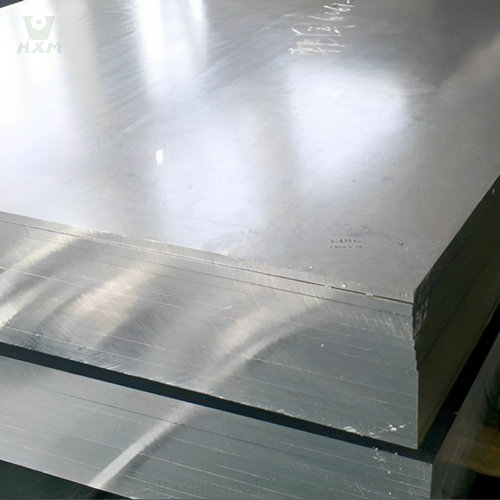

304 stainless steel sheets 4×8

Stainless steel sheets with dimensions of 4 feet by 8 feet. These sheets are made from the alloy 304, which offers corrosion resistance and is commonly used in various applications, including construction, automotive, and kitchen equipment.

alloy steel vs stainless steel

Alloy steel blends diverse elements for enhanced mechanical properties, ideal for machinery. Stainless steel contains ≥10.5% chromium for exceptional corrosion resistance, suitable for applications from kitchenware to industry, emphasizing durability and appearance.

420 stainless steel

420 stainless steel is a martensitic alloy with 12% chromium content. It provides good corrosion resistance, high hardness, and is often used in applications requiring high wear resistance like surgical instruments, cutlery, and certain industrial tools.

What is 18/8 stainless steel?

18/8 stainless steel, also known as Type 304 stainless steel, consists of 18% chromium and 8% nickel in its composition. This alloy offers excellent corrosion resistance, good formability, and durability. It is widely used in various applications, including kitchenware, food processing equipment, and architectural components due to its favorable balance of properties.

904L Stainless Steel

904L stainless steel is an austenitic superalloy with 21% chromium, 25% nickel, and 4.5% molybdenum. It exhibits exceptional corrosion resistance, especially in harsh environments like chemical processing, pharmaceuticals, and seawater applications.

15-5PH Stainless Steel

15-5PH stainless steel is a precipitation-hardening alloy with 15% chromium, 5% nickel, and 3% copper. It delivers high strength, corrosion resistance, and is used in aerospace, nuclear, and chemical processing applications.