15-5PH Stainless Steel

15-5PH stainless steel is a precipitation-hardening alloy with 15% chromium, 5% nickel, and 3% copper. It delivers high strength, corrosion resistance, and is used in aerospace, nuclear, and chemical processing applications.

317L Stainless Steel

317L stainless steel is an austenitic low carbon alloy with 18% chromium, 11% nickel, and 3% molybdenum. It offers superior corrosion resistance in acidic environments, making it suitable for chemical, petrochemical, and pharmaceutical applications.

347 stainless steel

347 stainless steel is an austenitic heat-resistant alloy with 17% chromium and 10% nickel. It contains niobium, offering excellent intergranular corrosion resistance. Used in high-temperature applications like aircraft and petrochemical industries.

309 stainless steel

309 stainless steel is an austenitic heat-resistant alloy with 23% chromium and 12% nickel. It exhibits excellent high-temperature strength and oxidation resistance, making it suitable for furnace components, heat exchangers, and high-temperature applications in various industries.

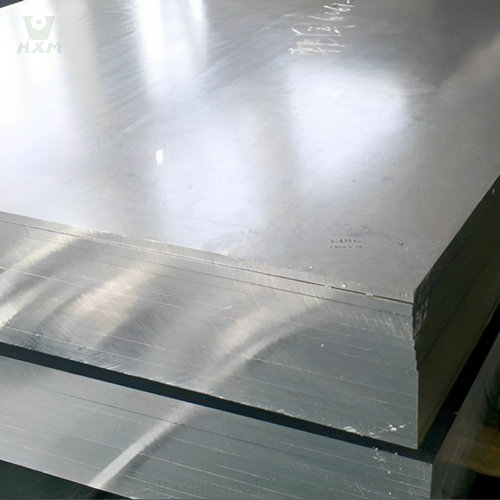

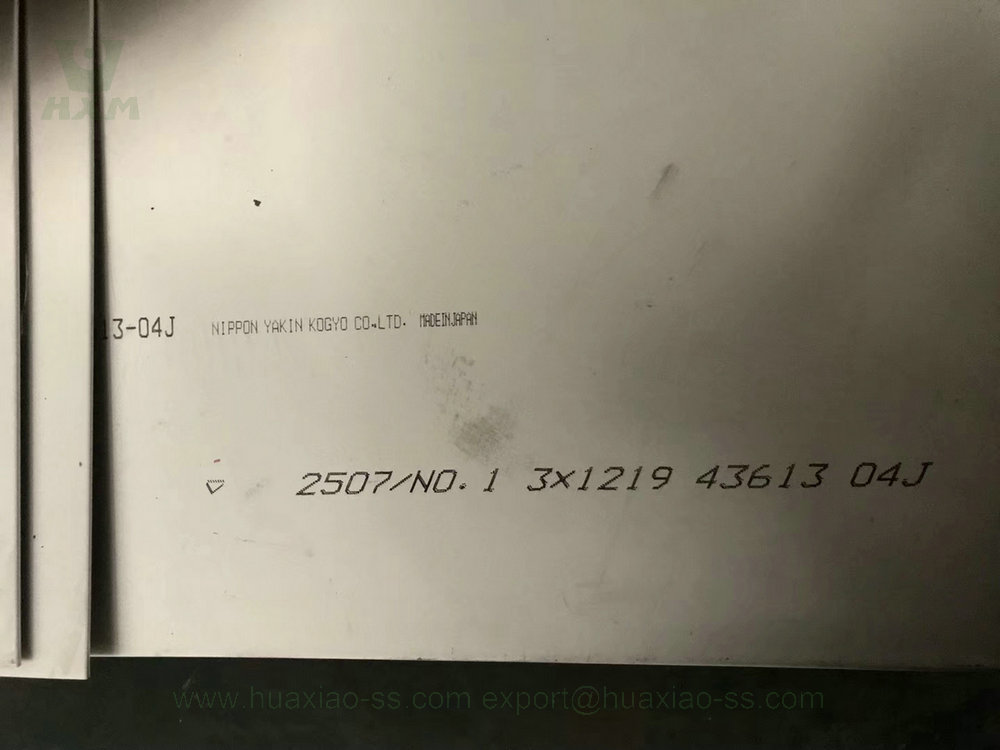

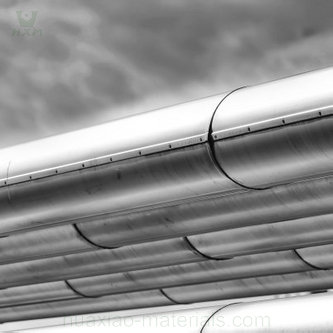

Duplex 2507 Stainless Steel

Duplex 2507 stainless steel is a super duplex alloy with 25% chromium, 7% nickel, and increased levels of molybdenum and nitrogen. It offers exceptional strength, corrosion resistance, and is used in critical applications like offshore oil and gas, chemical processing, and marine environments.

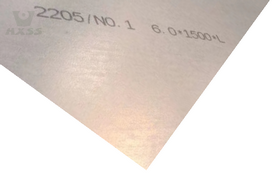

Duplex 2205 Stainless Steel

Duplex 2205 stainless steel is a ferritic-austenitic duplex alloy with 22% chromium, 5% nickel, and 3% molybdenum. It provides superior strength, corrosion resistance, and is used in demanding applications such as offshore platforms, chemical processing, and marine environments.

321 stainless steel

321 stainless steel is a stabilized austenitic stainless steel containing titanium. It offers excellent high-temperature strength and corrosion resistance, making it suitable for applications in aerospace, petrochemical, and automotive industries.

630 stainless steel

630 stainless steel, also known as 17-4PH, is a precipitation-hardening alloy with 17% chromium, 4% nickel, and 4% copper. It offers excellent strength, corrosion resistance, and is used in aerospace, petrochemical, medical, and marine applications.

18 10 stainless steel sheet plates

18 10 STAINLESS STEEL PLATE SHEET The 18/10 stainless steel sheet plate is a high-quality alloy consisting of 18% chromium and 10% nickel.Corrosion-resistant alloy with high chromium and nickel content. Ideal for kitchenware, food processing, and architectural projects. Durable and visually appealing. 18 10 STAINLESS STEEL PLATE sheet Type Stainless Steel Sheet / Stainless Steel […]

Etched stainless steel sheet

Etched stainless steel sheet is created by selectively removing the surface material to create decorative patterns or designs.