| High Strength | Exhibits higher mechanical strength compared to standard austenitic stainless steels like 304 and 316. |

| Corrosion Resistance | Offers exceptional resistance to various corrosive environments, including chloride-rich and acidic conditions. |

| Stress Corrosion Cracking (SCC) Resistance | Shows outstanding resistance against stress corrosion cracking in harsh and corrosive environments. |

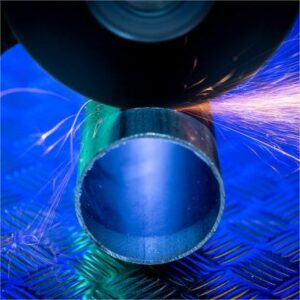

| Weldability | Readily weldable using standard techniques; proper heat input control is essential for retaining properties. |

| High Temperature Strength | Maintains good mechanical properties at elevated temperatures, suitable for applications with thermal cycling. |

| Abrasion Resistance | Demonstrates good resistance to erosion and abrasion, making it ideal for mining, marine, and oil and gas. |

| Biocompatibility | Exhibits good biocompatibility, suitable for certain medical and bioengineering applications. |

| ClSCC Resistance | Shows excellent resistance to chloride stress corrosion cracking, making it ideal for marine environments. |

| Pressure Vessel and Heat Exchanger Applications | Widely used in chemical processing and petrochemical industries due to excellent mechanical and corrosion resistance. |

| Seawater and Marine Applications | Preferred choice for seawater systems, shipbuilding, and offshore structures due to resistance to pitting and crevice corrosion. |

| Desalination and Water Treatment | Suitable for desalination plants and water treatment facilities where exposure to brine or saline solutions is common. |

| Pulp and Paper Industry | Widely used in equipment like digesters and bleachers, offering resistance to corrosive chemicals and high temperatures. |

| Chemical Processing | Finds applications in chemical processing equipment for handling corrosive chemicals and solutions. |

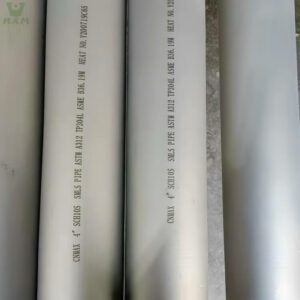

| Oil and Gas Industry | Extensively used for pipelines, wellhead components, and subsea equipment due to resistance to corrosion and SCC. |

| Low Thermal Expansion | Exhibits low thermal expansion, beneficial for applications requiring dimensional stability under varying temperatures. |