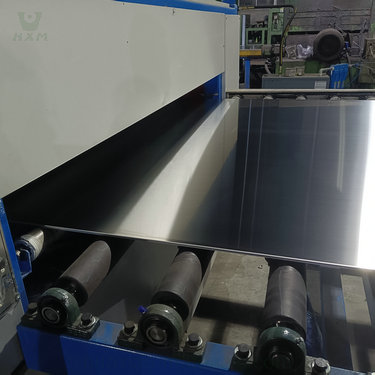

Density of stainless steel

The density of stainless steel can vary depending on the specific alloy composition. On average, the density ranges from about 7.70 to 8.05 grams per cubic centimeter (g/cm³) or approximately 0.278 to 0.291 pounds per cubic inch (lb/in³).