When selecting suppliers for stainless steel products, several factors should be carefully considered to ensure that you obtain high-quality materials and reliable services. Here are the key factors to take into account:

Quality of Products: Look for suppliers who provide stainless steel products that meet industry standards and specifications. Assess the supplier’s reputation for delivering high-quality materials that are free from defects and meet your specific requirements.

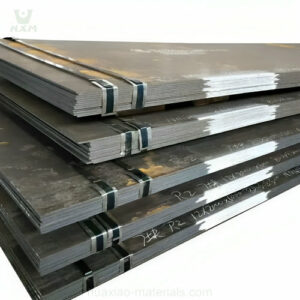

Material Grades and Specifications: Ensure that the supplier offers a wide range of stainless steel grades and sizes to match your project’s needs. Different applications may require specific grades (e.g., 304, 316, Duplex, etc.) and specifications, so having options available is essential.

Experience and Reputation: Choose suppliers with a proven track record of supplying stainless steel products to various industries. Check for customer reviews, testimonials, and references to gauge the supplier’s reliability and reputation.

Certifications and Compliance: Verify that the supplier holds necessary certifications, such as ISO 9001, ISO 14001, or specific industry certifications. Compliance with international standards ensures that the materials are produced and handled following established quality and environmental guidelines.

Delivery and Lead Times: Prompt and on-time delivery is crucial for your project’s success. Evaluate the supplier’s ability to meet your delivery deadlines and their lead times for custom orders.

Inventory and Stock Levels: Check if the supplier maintains sufficient stock levels of commonly requested stainless steel products. Adequate inventory ensures shorter lead times and availability of materials when you need them.

Technical Support and Expertise: Opt for suppliers that offer technical support and expertise. They should be knowledgeable about stainless steel properties, applications, and suitable grades for specific projects. Access to expert advice can be invaluable in making informed decisions.

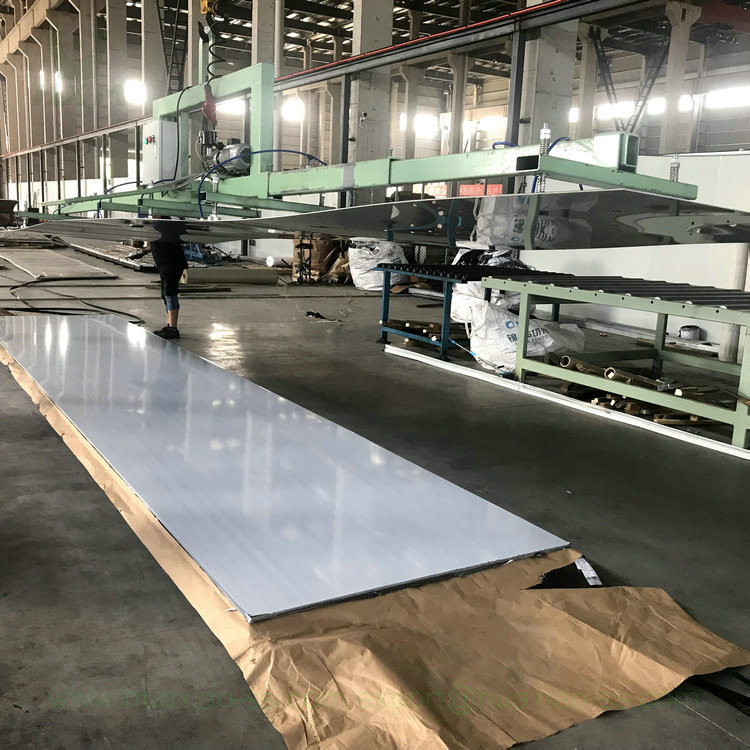

Packaging and Handling: Consider the supplier’s packaging and handling procedures to ensure that stainless steel products arrive in optimal condition, free from damage and contamination.

Cost and Pricing: While cost is a factor, prioritize overall value over the lowest price. Evaluate the supplier’s pricing in relation to the quality of products and services provided.

Customer Service: Excellent customer service is crucial for a smooth and satisfactory buying experience. Choose suppliers who are responsive, communicative, and willing to address any concerns promptly.

Global Reach and Distribution: For international projects, consider suppliers with a global reach and a reliable distribution network. This ensures seamless access to stainless steel products regardless of the project’s location.

By carefully evaluating these factors and conducting thorough research on potential suppliers, you can find a reliable partner to fulfill your stainless steel product needs and support the success of your projects.