Is 18 8 stainless steel an environmentally friendly material?

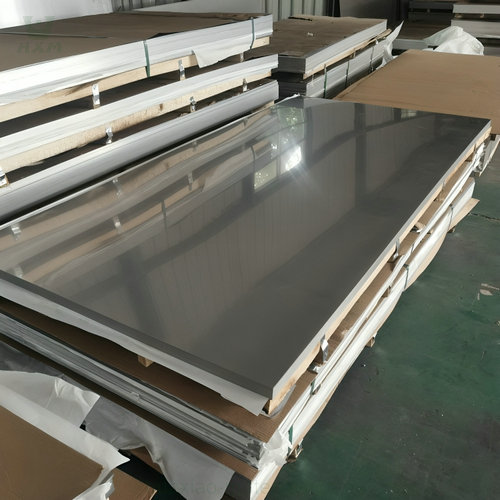

18-8 stainless steel, also known as 304 stainless steel, is a commonly used material in various industries. It boasts a combination of desirable qualities, including corrosion resistance, durability, and ease of maintenance. But the question remains: is 18-8 stainless steel an environmentally friendly material?

In this brief introduction, we will explore the environmental aspects of 18-8 stainless steel. We will delve into its production, recyclability, longevity, and its potential to reduce the environmental footprint of various applications. By doing so, we aim to provide a concise overview of whether 18-8 stainless steel aligns with sustainability goals in an increasingly eco-conscious world.