Stainless steel square bars offer several advantages in terms of their shape and utility, making them a versatile choice for various applications. Here are some key advantages:

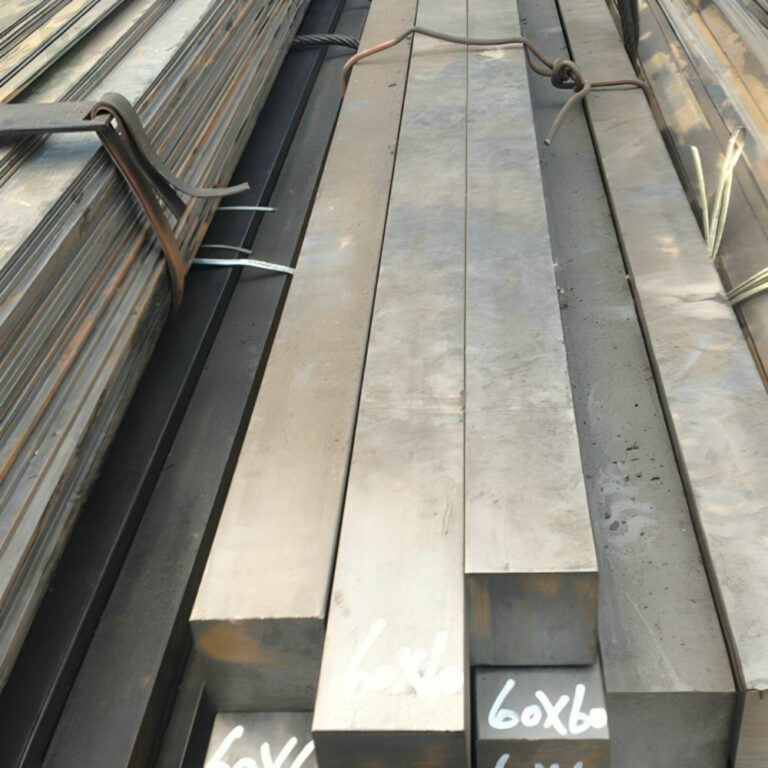

Uniform Geometry: Stainless steel square bars have a consistent square shape with equal-length sides, providing a balanced and symmetrical profile. This uniform geometry simplifies machining, cutting, and assembly processes, ensuring precise fit and alignment in applications.

Enhanced Strength: The square cross-sectional shape of these bars provides increased strength and load-bearing capacity compared to round bars of similar dimensions. This makes stainless steel square bars suitable for structural and heavy-duty applications.

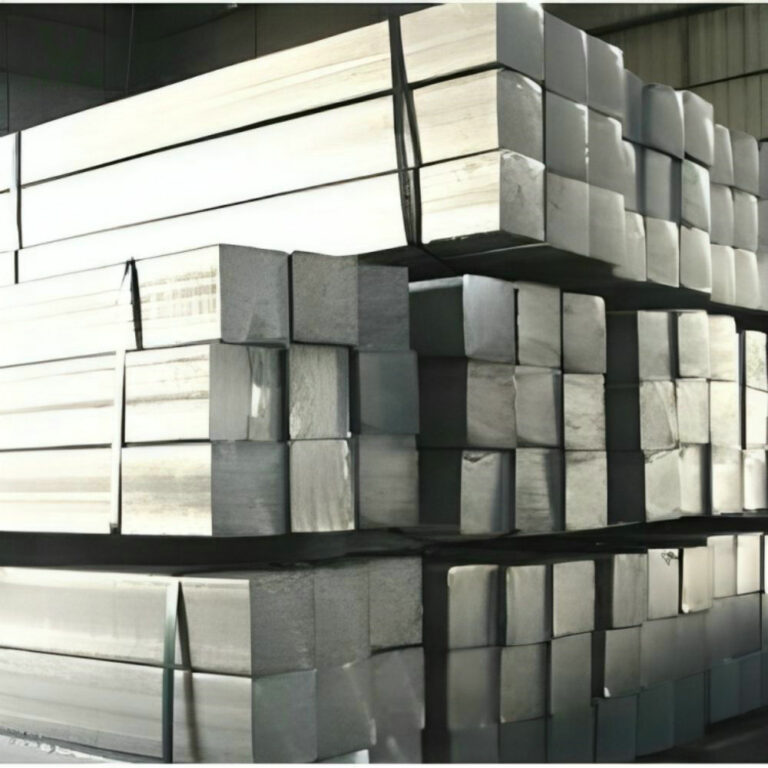

Ease of Handling: The square shape allows for easier handling and transportation, as the bars can be stacked neatly and securely. This is particularly beneficial in manufacturing and construction where efficient material handling is essential.

Versatility: Stainless steel square bars are versatile and can be employed in a wide range of applications, from structural components to precision machine parts. Their adaptability makes them suitable for use in various industries.

Excellent Machinability: Stainless steel square bars are known for their excellent machinability. They can be easily cut, drilled, milled, and threaded to create custom components with precise dimensions, which is crucial in manufacturing.

Corrosion Resistance: Like other stainless steel forms, square bars offer exceptional corrosion resistance, making them suitable for applications in harsh environments, marine settings, and corrosive industrial conditions.

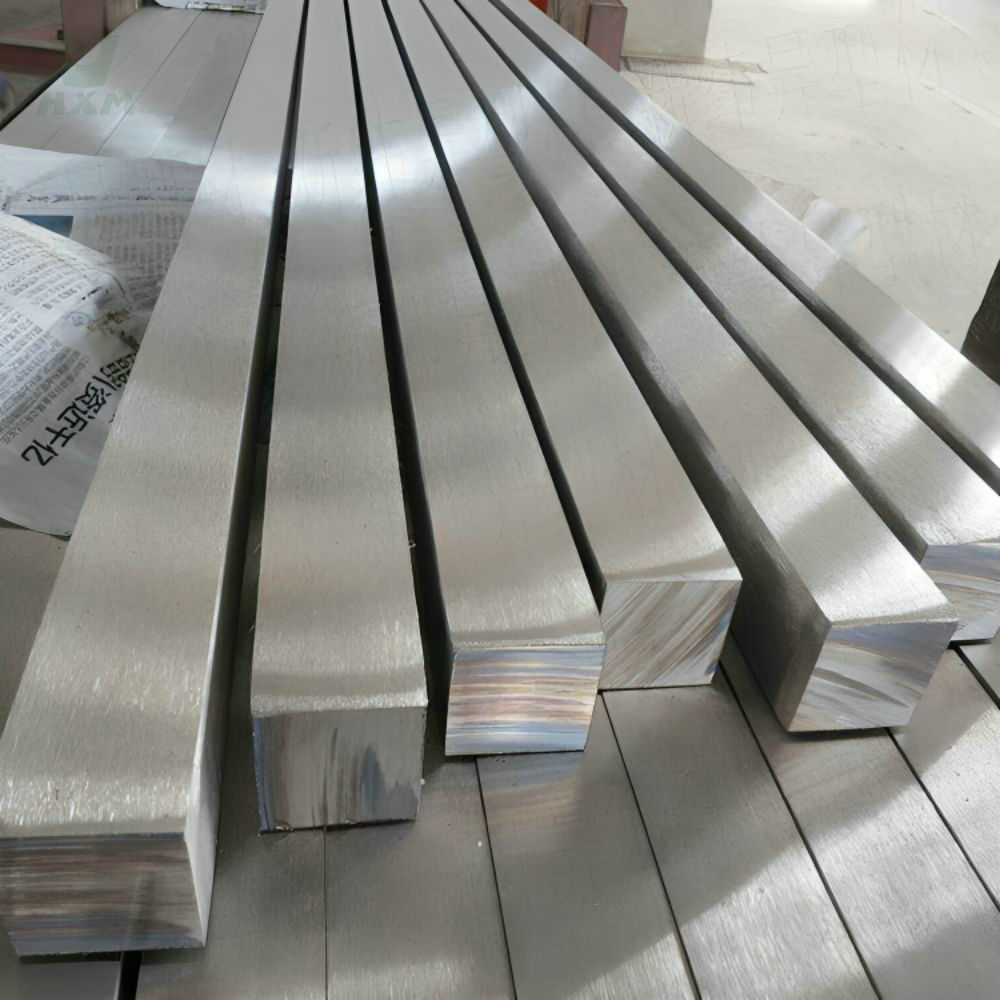

Aesthetic Appeal: Stainless steel square bars can have an attractive and polished finish, making them suitable for architectural and decorative elements in construction and design projects.

Durability: Stainless steel square bars are highly durable and can withstand wear and tear, making them long-lasting and cost-effective over their service life.

Hygienic Properties: Stainless steel’s ease of cleaning and resistance to bacterial growth make square bars suitable for applications in industries like food processing, healthcare, and pharmaceuticals.

High Temperature Resistance: Stainless steel square bars maintain their strength and integrity at high temperatures, making them suitable for applications involving elevated heat or thermal stress.

Recyclability: Stainless steel is a recyclable material, and square bars can be recycled and repurposed, contributing to sustainability efforts and reducing environmental impact.

Customization: Stainless steel square bars are available in various grades, sizes, and surface finishes, allowing for customization to meet specific project requirements.

In summary, stainless steel square bars offer a combination of strength, uniformity, versatility, and corrosion resistance that makes them valuable across a broad spectrum of industries and applications. Their ease of machining and customization further enhances their utility, making them a preferred choice for many engineering and construction projects.