What is stainless steel clad plate?

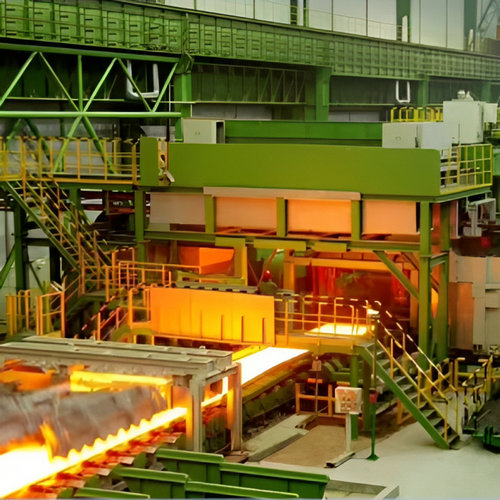

The stainless steel clad plate is a clad steel plate made of a carbon steel base and a stainless steel cladding. Its main feature is that carbon steel and stainless steel form a strong metallurgical bond. It can be processed by hot pressing, cold bending, cutting, welding, etc., and has good process performance.