Explore the best applications of 416R stainless steel

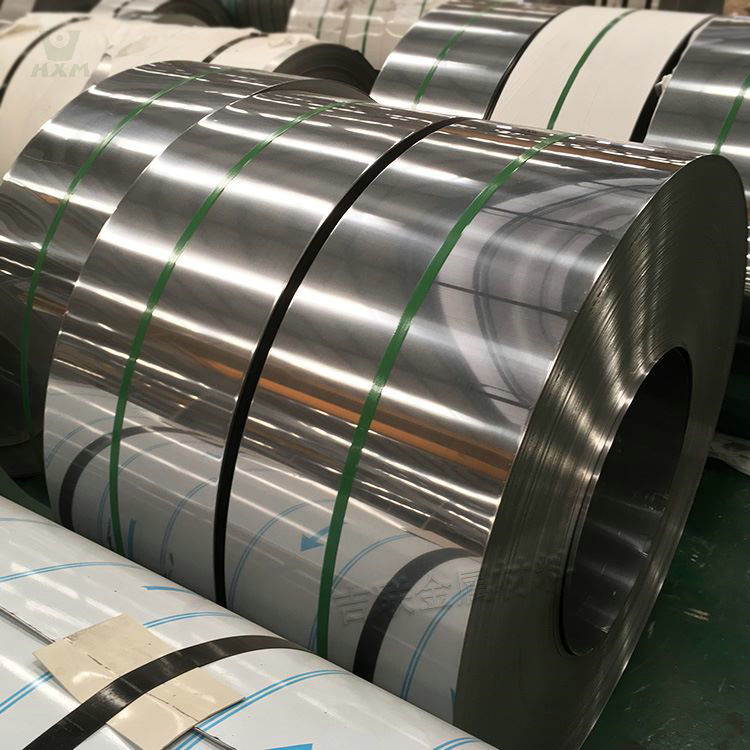

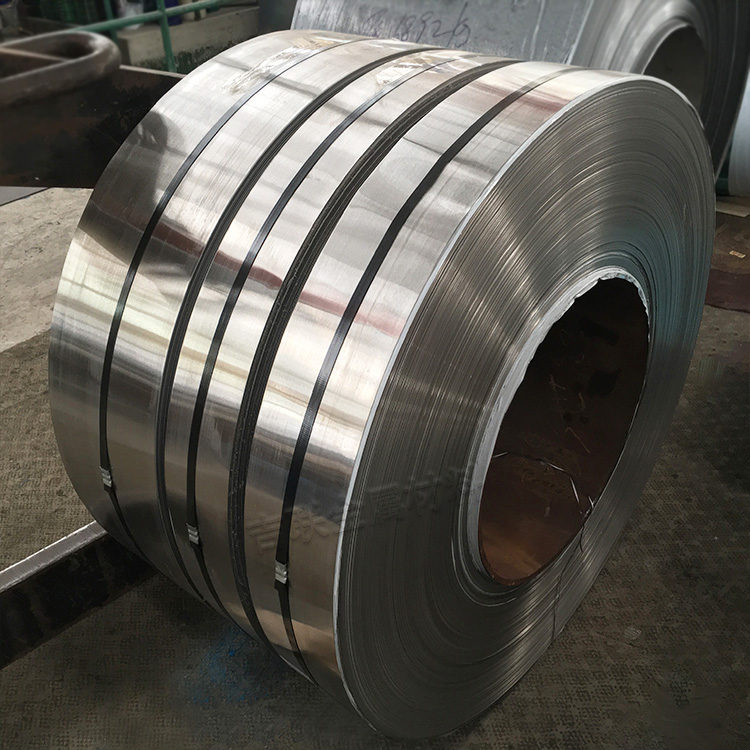

416R stainless steel is a premium, highly machinable alloy used in firearm barrels. Its excellent machining properties and corrosion resistance make it ideal for precision rifle and handgun barrels.