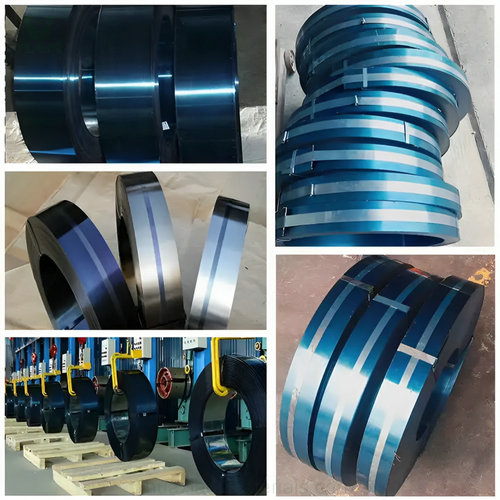

65mn spring steel sheet

65mn spring steel sheets are known for their high yield strength and are commonly used in the manufacturing of coil springs, leaf springs, and various automotive and machinery components.

65mn spring steel sheets are known for their high yield strength and are commonly used in the manufacturing of coil springs, leaf springs, and various automotive and machinery components.

| Material | Dimensions (ThicknessWidthLength) | Single Weight (Tons) |

|---|---|---|

| 65MN | 2.751010/1250C | 16/20 |

| 65MN | 2.801010/1250C | 16/20 |

| 65MN | 3.001010/1250C | 16/20 |

| 65MN | 3.251010/1250C | 16/20 |

| 65MN | 3.501010/1250C | 16/20 |

| 65MN | 3.751010/1250C | 16/20 |

| … | … | … |

| 65MN | 14.001010/1250C | 16/20 |

| Mechanical Properties | Range |

|---|---|

| Tensile Strength (σb) MPa | 825 – 925 |

| Elongation (δ10) % | 14 – 22.5 |

| Reduction of Area (ψ) % | Not greater than 10 |

| Hardness (HB) | Hot Rolled: ≤ 302HB |

| Hot Rolled + Heat Treated: ≤ 321HB |

| Chemical Composition | Range |

|---|---|

| Carbon (C) | 0.62 – 0.70 |

| Silicon (Si) | 0.17 – 0.37 |

| Manganese (Mn) | 0.90 – 1.20 |

| Sulfur (S) | ≤ 0.035 |

| Phosphorus (P) | ≤ 0.035 |

| Chromium (Cr) | ≤ 0.25 |

| Nickel (Ni) | ≤ 0.30 |

| Copper (Cu) | ≤ 0.25 |

65Mn spring steel sheet is commonly used in various applications due to its excellent spring properties and wear resistance. Some of the common applications include:

Spring Manufacturing: 65Mn is widely used in the production of various types of springs, including coil springs, flat springs, and leaf springs. It is valued for its good combination of high strength and elasticity, making it suitable for applications where springs need to withstand repeated loads.

Automotive Industry: Leaf springs and suspension components in vehicles often use 65Mn spring steel due to its durability and resilience. It provides the necessary support and flexibility for automotive suspensions.

Agricultural Machinery: Components of agricultural machinery such as plowshares, harrows, and tiller blades benefit from the wear resistance and toughness of 65Mn steel. It can handle the stresses and strains of agricultural work.

Manufacturing Tools: 65Mn is used for making a variety of hand tools, including chisels, scrapers, and cutting tools. Its hardness and ability to hold an edge make it suitable for cutting and shaping materials.

Hardware and Fasteners: Springs, washers, and various hardware components are often made from 65Mn steel due to its resilience and resistance to deformation under load.

Construction: It can be used in construction applications where high-stress components, such as brackets and clips, are needed.

Firearms and Weaponry: Some firearm components, particularly in older firearms, may be made from 65Mn spring steel due to its toughness and durability.

Hand Tools: It is used in the manufacturing of hand tools such as knives, garden tools, and saw blades.

Lock Springs: Springs used in locks and lock mechanisms often utilize 65Mn spring steel due to its reliability and resistance to wear.

Electrical and Electronic Industries: Contacts and connectors in electrical and electronic devices may use 65Mn spring steel due to its electrical conductivity and spring properties.

It’s important to note that the specific grade and heat treatment of 65Mn can vary based on the application to achieve the desired properties. This versatile steel is valued for its ability to provide the necessary strength and resilience in a wide range of industrial and manufacturing settings.

65Mn spring steel sheets can undergo various surface treatment options to enhance their performance, durability, and corrosion resistance. Some of the common surface treatments for 65Mn spring steel include:

Phosphating: Phosphating involves the application of a phosphate coating on the steel surface. This process enhances corrosion resistance and provides a good base for subsequent coatings, such as paints or lubricants.

Galvanizing: Galvanizing involves immersing the steel in a bath of molten zinc, forming a protective zinc coating on the surface. This process is effective in preventing corrosion, especially in outdoor or harsh environments.

Electroplating: Electroplating can be used to apply a thin layer of a different metal (e.g., chromium or nickel) onto the steel surface. This not only enhances corrosion resistance but also improves aesthetics and wear resistance.

Powder Coating: Powder coating involves applying a dry powder paint onto the steel surface and then curing it with heat. This process provides a durable and protective layer that is resistant to corrosion, chemicals, and UV radiation.

Painting: Applying paint or other organic coatings can protect the steel surface from corrosion and improve aesthetics. Primers are often used before applying paint to enhance adhesion.

Oiling: A thin layer of oil can be applied to the steel surface to provide temporary corrosion protection. This is commonly used for steel that is in storage or transit.

Passivation: Passivation is a chemical process used to remove free iron from the surface of stainless steels, improving their corrosion resistance.

Shot Peening: Shot peening is a mechanical surface treatment that involves bombarding the steel surface with small, spherical media (shots). This process induces compressive stresses, improving fatigue resistance.

Bluing: Bluing is a chemical surface treatment that creates a thin, protective oxide layer on the steel surface, enhancing corrosion resistance and providing a dark finish.

The choice of surface treatment depends on the specific application and the desired properties. For example, if corrosion resistance is a primary concern, galvanizing or electroplating may be preferred. If aesthetics and durability are important, powder coating or painting may be suitable. The selection of a surface treatment should consider the environmental conditions and the intended use of the 65Mn spring steel sheets.

65Mn spring steel sheet, like many other materials, has its limitations in high-pressure and high-temperature environments, such as those encountered in oil and gas drilling equipment. Its performance under such conditions depends on several factors, including the specific grade and heat treatment of the steel, as well as the duration and severity of exposure. Here are some considerations:

Temperature Resistance: 65Mn spring steel has relatively good temperature resistance for spring materials but may not be suitable for extremely high-temperature applications. The heat treatment process used can also influence its temperature resistance. If exposed to temperatures exceeding its critical temperature, it may lose its mechanical properties.

Pressure Resistance: The pressure resistance of 65Mn spring steel depends on the thickness and strength of the material. Thicker and stronger sheets are more likely to withstand high-pressure environments. The steel’s mechanical properties, including yield strength and tensile strength, play a crucial role in determining its pressure resistance.

Corrosion Resistance: The corrosion resistance of 65Mn spring steel is moderate, and it may be susceptible to corrosion in harsh environments, especially if not properly protected. In the oil and gas industry, where exposure to corrosive substances is common, additional measures like coatings or corrosion-resistant alloys may be required.

Fatigue Resistance: 65Mn spring steel is known for its excellent fatigue resistance. This property is beneficial in applications involving cyclic loading, as is often the case in drilling equipment subjected to dynamic forces.

Heat Treatment: The heat treatment process can significantly affect the performance of 65Mn spring steel. Proper heat treatment, including quenching and tempering, can enhance its mechanical properties and resistance to high-pressure and high-temperature conditions.

Material Selection: For demanding oil and gas drilling equipment applications, engineers often consider specialized alloys and materials designed for high-temperature and high-pressure environments, such as certain grades of stainless steel or nickel-based alloys.

In summary, while 65Mn spring steel sheet can be suitable for some applications in the oil and gas industry, it may not be the best choice for extremely high-pressure and high-temperature conditions without appropriate modifications or additional protective measures. Engineers and material specialists typically assess the specific requirements and environmental factors to select the most suitable materials for critical equipment in such industries.

Proper storage and transportation practices are essential to ensure the quality and performance of 65Mn spring steel sheets, as well as to prevent damage or deterioration. Here are some recommendations:

Indoor Storage: Whenever possible, store 65Mn spring steel sheets indoors in a dry, clean, and well-ventilated area. Exposure to moisture, humidity, or extreme temperature variations should be avoided.

Protection from Elements: If outdoor storage is necessary, cover the steel sheets with weather-resistant tarps or protective coatings to shield them from rain, snow, and direct sunlight.

Avoid Contact with Floor: Keep the steel sheets elevated off the ground using wooden pallets, racks, or other suitable platforms to prevent contact with moisture and to allow air circulation.

Stacking: If stacking is required, use suitable stacking supports between layers to prevent deformation, warping, or surface damage. Avoid excessive stacking height to prevent overloading and deformation.

Secure Loading: When loading 65Mn spring steel sheets onto transport vehicles, ensure that they are properly secured and stacked to prevent shifting, sliding, or damage during transit.

Protective Packaging: Use appropriate packaging materials, such as plastic or cardboard separators, to prevent contact between individual sheets during transportation. This helps avoid surface scratches and damage.

Weather Protection: If the steel sheets are transported on an open vehicle, ensure they are adequately covered or tarped to protect them from adverse weather conditions.

Handling Equipment: Use suitable lifting and handling equipment, such as forklifts or cranes, to load and unload steel sheets safely to prevent bending or surface damage.

Avoid Rough Handling: Train personnel involved in handling and transportation to exercise care and avoid rough handling that could lead to dents, scratches, or other damage.

Documentation: Ensure that all necessary documentation, such as shipping records, quality certificates, and safety data sheets, accompanies the shipment.

Inspect Upon Receipt: Upon receipt of the steel sheets, inspect them for any visible damage or discrepancies. If any issues are identified, document them and report to the supplier or relevant authorities promptly.

Proper storage and transportation practices are crucial to preserving the quality and integrity of 65Mn spring steel sheets, which can impact their performance in various applications. Following these recommendations can help minimize the risk of damage and ensure that the steel sheets meet the intended specifications.

When choosing a 65Mn spring steel sheet manufacturer, several factors should be considered to ensure you partner with a reliable and reputable supplier. Here are some key factors to take into account:

By carefully evaluating these factors and conducting due diligence, you can select a 65Mn spring steel sheet manufacturer that aligns with your project’s requirements, quality standards, and budget constraints.

Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours