Selecting the right A286 stainless steel supplier is crucial to ensure the quality and reliability of your materials. Here are some important factors to consider when choosing A286 stainless steel suppliers:

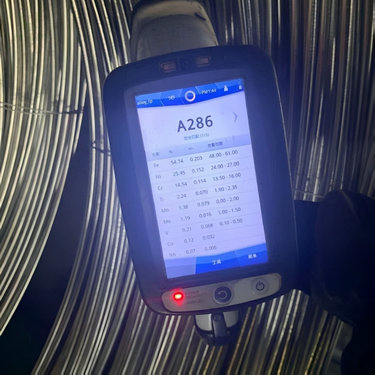

Quality and Certification: Ensure that the supplier provides A286 stainless steel that meets relevant industry standards and specifications, such as ASTM A638/A638M. Look for suppliers that offer materials with appropriate certifications, including material test reports (MTRs) that detail the chemical composition, mechanical properties, and other quality attributes of the material.

Experience and Reputation: Choose suppliers with a proven track record of supplying high-quality A286 stainless steel to industries that demand reliability, such as aerospace, automotive, and oil and gas. Research their reputation, client feedback, and industry affiliations to assess their credibility.

Product Range: Check if the supplier offers a comprehensive range of A286 stainless steel products, including sheets, plates, bars, and tubes, to cater to different application requirements.

Supply Capacity: Ensure that the supplier has the capacity to fulfill your order requirements within your specified timeline. A reliable supplier should have adequate stock and production capabilities to meet your needs, even during peak demand periods.

Customization: If your application requires specific sizes, dimensions, or forms of A286 stainless steel, inquire if the supplier can provide customized solutions to meet your requirements.

Technical Support: Look for suppliers that have knowledgeable technical support teams who can assist you with product selection, application guidance, and any technical questions you may have.

Quality Assurance Processes: Inquire about the supplier’s quality control procedures, inspection processes, and testing methodologies to ensure that the materials you receive meet the required standards and specifications.

Delivery and Logistics: Consider the supplier’s ability to deliver the materials to your location efficiently and securely. Timely and safe delivery is important to avoid disruptions in your production processes.

Price and Cost: While cost is a consideration, it’s important not to compromise on quality for the sake of lower prices. Compare the prices of A286 stainless steel materials from multiple suppliers while considering the overall value, including quality and service.

Customer Support: Evaluate the supplier’s customer service responsiveness, communication, and willingness to address your inquiries and concerns promptly.

References and Recommendations: If possible, seek recommendations from industry peers or colleagues who have experience with A286 stainless steel suppliers. Their insights can provide valuable information about potential suppliers.

Location: Consider the geographical location of the supplier, as proximity can impact shipping costs and lead times.

Sustainability: If sustainability is a priority for your business, inquire about the supplier’s environmental practices, such as recycling and waste reduction initiatives.

Choosing the right A286 stainless steel supplier requires careful research and due diligence. By considering these factors and conducting thorough evaluations, you can select a supplier that aligns with your quality, reliability, and performance requirements.