stainless steel hex bar

Stainless steel hex bars, with their six-sided profile, are commonly used in applications requiring precision and strength, such as machinery manufacturing, fasteners, and construction where a secure grip is essential.

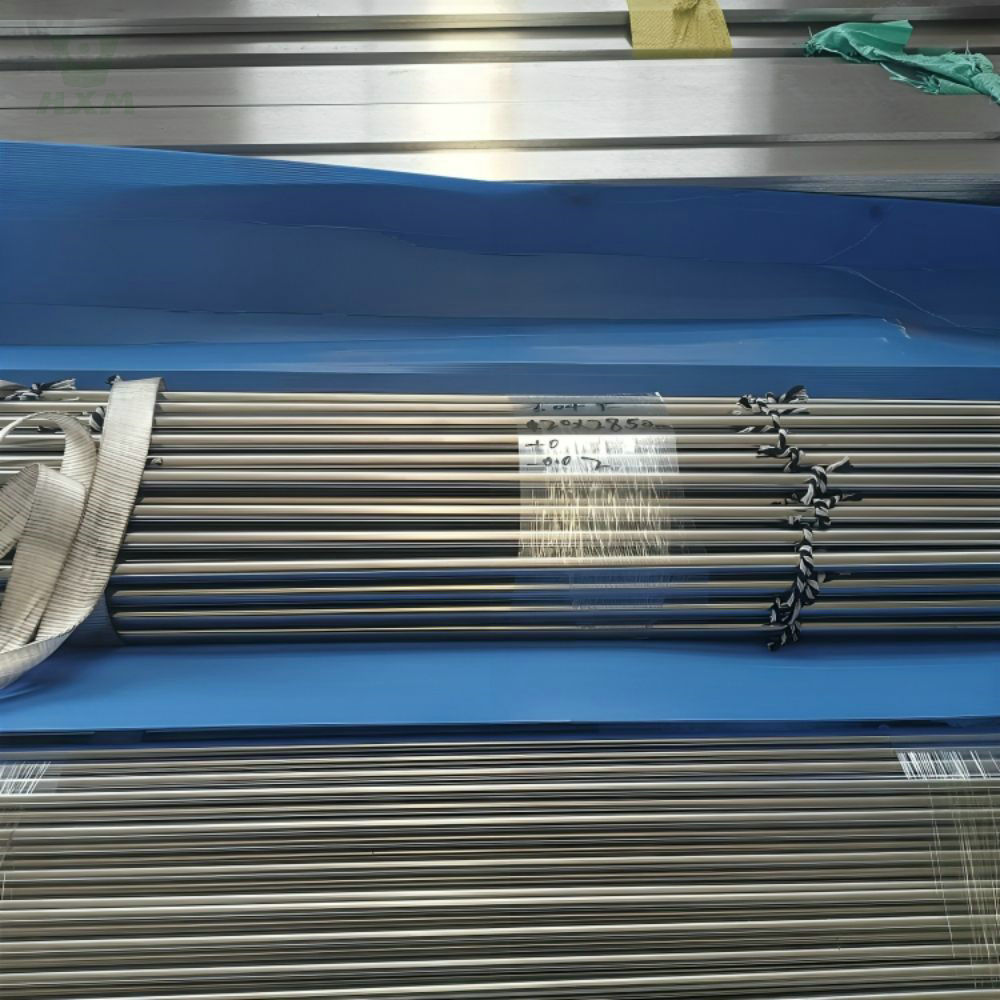

430 stainless steel round bar

430 stainless steel round bars are cost-effective and suited for applications in less corrosive environments. They are used in appliances, kitchen utensils, and decorative trim due to their affordability and moderate corrosion resistance.

304 stainless steel round bar

304 stainless steel round bars find versatile use across industries, including construction for structural support, food processing equipment, automotive components, and in architectural applications due to their corrosion resistance and strength.

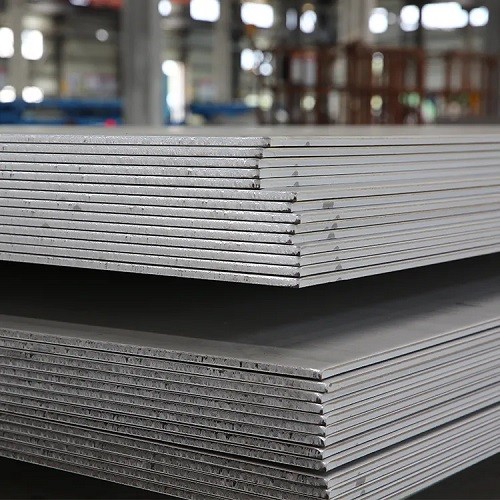

304 vs 430 stainless steel

304 stainless steel offers excellent corrosion resistance, making it ideal for food equipment and architectural applications. In contrast, 430 stainless steel has less corrosion resistance but is more cost-effective, suitable for less demanding environments like appliances.

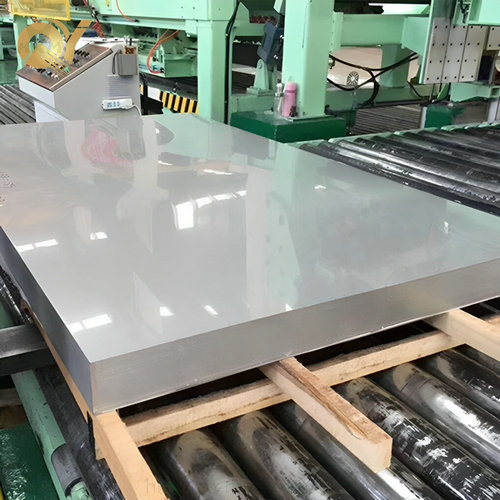

300 series stainless steel

The 300 series stainless steel is a group of austenitic alloys that exhibit exceptional corrosion resistance, strength, and weldability. These alloys are widely used in various industries due to their superior properties.

Is 18 8 stainless steel an environmentally friendly material?

18-8 stainless steel, also known as 304 stainless steel, stands as a commendable choice from an environmental perspective.

stainless steel bar

Stainless steel bars come in various shapes, including round, square, and hexagonal. They find use across industries in structural support, machinery parts, and automotive components due to their strength and corrosion resistance.

Mastering PVD Stainless Steel Coatings: A Guide to Durability, Aesthetics, and Applications

PVD, which stands for Physical Vapor Deposition, is an advanced surface coating technology. It improves the performance of stainless steel by evaporating solid materials in a vacuum environment and depositing them onto the stainless steel surface. This process can enhance stainless steel’s wear resistance, corrosion resistance, and offer a wide range of colors and surface effects, making it highly popular in various industries, such as construction, automotive, and appliances.

440a stainless steel

440A stainless steel is a high-carbon martensitic alloy with 16-18% chromium. It provides good hardness, corrosion resistance, and is commonly used in cutlery and surgical instruments.

410 stainless steel vs 304

410 stainless steel has higher strength and hardness, suitable for wear-resistant applications.304 stainless steel offers better corrosion resistance and versatility for various environments and uses.