What is stainless steel clad plate?

The stainless steel clad plate is a clad steel plate made of a carbon steel base and a stainless steel cladding. Its main feature is that carbon steel and stainless steel form a strong metallurgical bond. It can be processed by hot pressing, cold bending, cutting, welding, etc., and has good process performance.

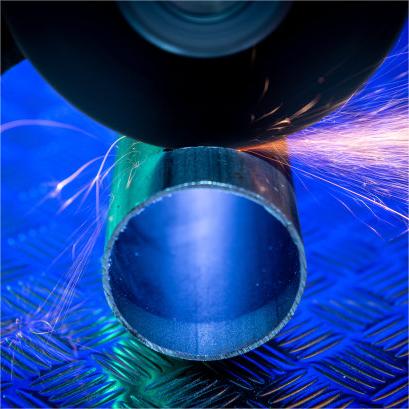

How to cut stainless steel pipes?

To cut stainless steel pipes, secure it, choose a suitable tool like a hacksaw or angle grinder, follow the marked line, and deburr the cut end for a smooth finish.

18-8 stainless steel vs 316

18-8 stainless steel, known as Type 304, consists of 18% chromium and 8% nickel. On the other hand, 316 stainless steel has 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. While both offer corrosion resistance, 316 provides better resistance to chloride environments, making it suitable for marine and chemical applications.

Is stainless steel magnetic?

The magnetic properties of stainless steels vary depending on their composition and treatment. In general, austenitic stainless steels are usually non-magnetic, while martensitic stainless steels may be magnetic.

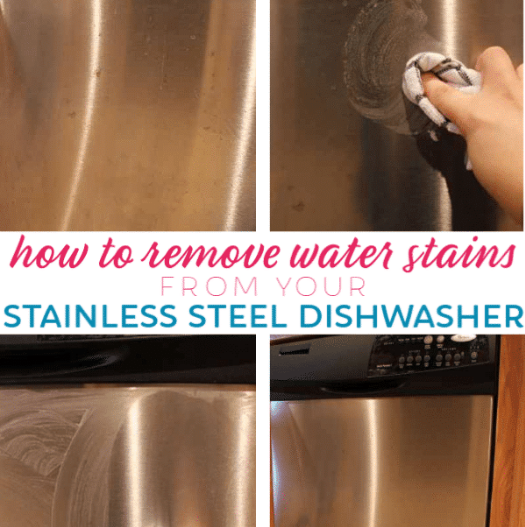

How to remove hard water stains from stainless steel?

To remove hard water stains from stainless steel, apply vinegar or lemon juice, gently scrub, then rinse and dry. Commercial cleaners or a baking soda paste can also be effective.

301 stainless steel

301 stainless steel is an austenitic alloy with 17% chromium and 7% nickel. It’s known for its high strength and excellent corrosion resistance. Used in various applications like springs, utensils, and automotive components.

alloy steel vs stainless steel

Alloy steel blends diverse elements for enhanced mechanical properties, ideal for machinery. Stainless steel contains ≥10.5% chromium for exceptional corrosion resistance, suitable for applications from kitchenware to industry, emphasizing durability and appearance.

What is 18/8 stainless steel?

18/8 stainless steel, also known as Type 304 stainless steel, consists of 18% chromium and 8% nickel in its composition. This alloy offers excellent corrosion resistance, good formability, and durability. It is widely used in various applications, including kitchenware, food processing equipment, and architectural components due to its favorable balance of properties.

Duplex 2507 stainless steel VS 2205

Duplex 2507 stainless steel has higher chromium, molybdenum, and nitrogen, providing superior corrosion resistance and strength compared to Duplex 2205. Both are used in demanding applications, but 2507 is favored in more aggressive environments like offshore and chemical processing

17-4 stainless steel vs 304

17-4 stainless steel offers higher strength, hardness, and corrosion resistance than 304. It finds specific applications in aerospace, petrochemical, medical, nuclear, marine, food processing, and firearms industries due to its unique properties.