The melting points of metals

The melting points of metals vary widely depending on the metal’s atomic structure and bonding.

The melting points of metals vary widely depending on the metal’s atomic structure and bonding.

Of course yes, aluminum conduct electricity. Aluminum is a metal known for its excellent electrical conductivity. This attribute makes it an attractive option for various applications in the electrical and electronics industries. Here’s a detailed exploration of aluminum’s electrical conductivity, its comparison with other metals, and its usage in electrical applications.

Aluminum does not rust in the traditional sense like iron does, because it lacks iron, which is essential for rust to form. However, aluminum can undergo a process known as aluminum corrosion, which is quite different from rusting. This difference is crucial because while “aluminum rust” is a misnomer, the corrosion of aluminum still involves a reaction with the environment, albeit through a different mechanism.

Carbon steel magnetic, mainly due to the presence of iron in it. Iron is a magnetic element, and when iron atoms are arranged to form a ferromagnetic region, they form a magnetic moment in that region and exhibit strong magnetism. Carbon steel is an alloy of iron and carbon, which has a high content of iron, and therefore carbon steel is also magnetic.

Yes, carbon steel rust when exposed to moisture and oxygen, as the iron content in carbon steel reacts with these elements to form iron oxide, commonly known as rust. However, rusting can be delayed or prevented through protective coatings, alloying, and regular maintenance.

304 stainless steel is a general-purpose stainless steel material that is widely used in a variety of applications due to its excellent corrosion resistance and processing properties.

Carbon steel pipe, with its excellent mechanical properties, corrosion resistance and processing performance, is widely used in many fields. This article will introduce the properties, types and applications of carbon steel pipe in detail.

In the vast realm of steel, both alloy steel and carbon steel emerge as pivotal players, each boasting unique characteristics that cater to diverse industrial applications. Understanding the nuanced distinctions between these two categories unveils a tapestry of properties, classifications, and application fields that shape their roles in the world of materials engineering.

Monel Steel vs Stainless Steel:Monel steel, a nickel-copper alloy, boasts exceptional corrosion resistance, making it ideal for marine and aerospace applications. It is non-magnetic and exhibits good strength at high temperatures. However, it comes at a higher cost. On the other hand, stainless steel, with varying alloys, offers cost-effectiveness, corrosion resistance, and versatility. The choice depends on specific needs, with Monel excelling in corrosive environments, while stainless steel caters to diverse applications economically.

Is stainless steel stronger than aluminum?Stainless steel is generally stronger than aluminum, offering higher tensile and yield strength, but it’s also denser.

Yes, 410 stainless steel magnetic. The reason for its magnetic properties lies in its microstructure. Stainless steels can be broadly categorized into two groups: ferritic and austenitic. 410 stainless steel is part of the ferritic stainless steel group.

Both Rex 45 and M4 are high-performance tool steels. The choice between them depends on specific applications. Rex 45 offers higher hardness and wear resistance, making it great for slicing and precision cutting tools. M4 is tougher and more impact-resistant, suitable for heavy-duty cutting and impact applications.

HSS (High-Speed Steel) contains alloying elements for high-temperature cutting, while HCS (High Carbon Steel) is a basic carbon steel. HSS is used for cutting tools, while HCS is used for general cutting applications.

Bearing steel is optimized for durability and load-bearing, ideal for bearings and gears. Stainless steel prioritizes corrosion resistance, used in applications requiring hygiene, like food processing and medical equipment.

The density of stainless steel can vary depending on the specific alloy composition. On average, the density ranges from about 7.70 to 8.05 grams per cubic centimeter (g/cm³) or approximately 0.278 to 0.291 pounds per cubic inch (lb/in³).

Tool steel contains alloying elements for durability and resistance to wear, ideal for tools and machinery. Carbon steel is primarily iron and carbon, chosen for general-purpose applications and affordability.

Tool steel contains alloying elements for durability and resistance to wear, ideal for tools and machinery. Carbon steel is primarily iron and carbon, chosen for general-purpose applications and affordability.

The 440 stainless steel guide helps users choose the best grade (440a stainless steel, 440b stainless steel, or 440c stainless steel) based on applications. It’s vital for cutlery, surgical instruments, and high-wear industrial components.

416R stainless steel is a premium, highly machinable alloy used in firearm barrels. Its excellent machining properties and corrosion resistance make it ideal for precision rifle and handgun barrels.

8Cr13MoV stainless steel is a budget-friendly option with good corrosion resistance and sharpness retention. It’s commonly used in low-cost knives and blades for everyday use and outdoor activities.

The 300 series stainless steel (e.g., 304) offers excellent corrosion resistance, suitable for applications like food processing and construction. In contrast, the 400 series stainless steel (e.g., 410) has lower corrosion resistance and is primarily used in areas like cutlery and appliance manufacturing.

The 400 series stainless steel includes alloys like 410 and 430, known for moderate corrosion resistance and cost-effectiveness. They’re used in cutlery, appliances, and automotive trim due to their affordability.

304 stainless steel offers excellent corrosion resistance, making it ideal for food equipment and architectural applications. In contrast, 430 stainless steel has less corrosion resistance but is more cost-effective, suitable for less demanding environments like appliances.

The 300 series stainless steel is a group of austenitic alloys that exhibit exceptional corrosion resistance, strength, and weldability. These alloys are widely used in various industries due to their superior properties.

18-8 stainless steel, also known as 304 stainless steel, stands as a commendable choice from an environmental perspective.

PVD, which stands for Physical Vapor Deposition, is an advanced surface coating technology. It improves the performance of stainless steel by evaporating solid materials in a vacuum environment and depositing them onto the stainless steel surface. This process can enhance stainless steel’s wear resistance, corrosion resistance, and offer a wide range of colors and surface effects, making it highly popular in various industries, such as construction, automotive, and appliances.

410 stainless steel has higher strength and hardness, suitable for wear-resistant applications.304 stainless steel offers better corrosion resistance and versatility for various environments and uses.

Silicon steel is magnetic due to its crystalline structure and silicon content. It’s used in transformers and motors for its high permeability and low core loss characteristics.

The stainless steel clad plate is a clad steel plate made of a carbon steel base and a stainless steel cladding. Its main feature is that carbon steel and stainless steel form a strong metallurgical bond. It can be processed by hot pressing, cold bending, cutting, welding, etc., and has good process performance.

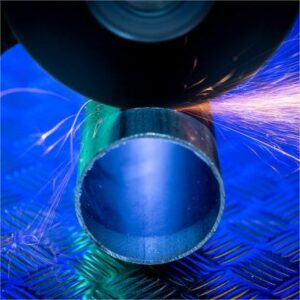

To cut stainless steel pipes, secure it, choose a suitable tool like a hacksaw or angle grinder, follow the marked line, and deburr the cut end for a smooth finish.

18-8 stainless steel, known as Type 304, consists of 18% chromium and 8% nickel. On the other hand, 316 stainless steel has 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. While both offer corrosion resistance, 316 provides better resistance to chloride environments, making it suitable for marine and chemical applications.

The magnetic properties of stainless steels vary depending on their composition and treatment. In general, austenitic stainless steels are usually non-magnetic, while martensitic stainless steels may be magnetic.

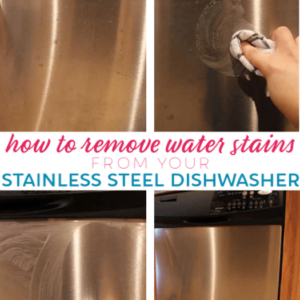

To remove hard water stains from stainless steel, apply vinegar or lemon juice, gently scrub, then rinse and dry. Commercial cleaners or a baking soda paste can also be effective.

301 stainless steel is an austenitic alloy with 17% chromium and 7% nickel. It’s known for its high strength and excellent corrosion resistance. Used in various applications like springs, utensils, and automotive components.

Alloy steel blends diverse elements for enhanced mechanical properties, ideal for machinery. Stainless steel contains ≥10.5% chromium for exceptional corrosion resistance, suitable for applications from kitchenware to industry, emphasizing durability and appearance.

18/8 stainless steel, also known as Type 304 stainless steel, consists of 18% chromium and 8% nickel in its composition. This alloy offers excellent corrosion resistance, good formability, and durability. It is widely used in various applications, including kitchenware, food processing equipment, and architectural components due to its favorable balance of properties.

Duplex 2507 stainless steel has higher chromium, molybdenum, and nitrogen, providing superior corrosion resistance and strength compared to Duplex 2205. Both are used in demanding applications, but 2507 is favored in more aggressive environments like offshore and chemical processing

17-4 stainless steel offers higher strength, hardness, and corrosion resistance than 304. It finds specific applications in aerospace, petrochemical, medical, nuclear, marine, food processing, and firearms industries due to its unique properties.

304 stainless steel contains higher chromium and nickel, providing excellent corrosion and heat resistance.409 stainless steel has higher carbon content and lower chromium.

201 stainless steel is a type of austenitic stainless steel with excellent corrosion resistance and high tensile strength. It contains lower nickel content compared to other stainless steel grades, making it more affordable. Commonly used in kitchenware, appliances, and automotive components.

Stainless steel #4 finish is a smooth and brushed surface treatment commonly applied to stainless steel surfaces. It provides a clean and non-reflective appearance, making it ideal for decorative and architectural applications.

To achieve a mirror finish on stainless steel, follow these steps: Clean the surface thoroughly. Apply a stainless steel polishing compound. Polish the surface using circular motions. Remove excess compound and clean the surface again. Optionally, apply a protective coating.

MIG welding stainless steel, or Metal Inert Gas welding, is a widely used process for joining stainless steel components. It involves the use of a consumable wire electrode and a shielding gas to create an electric arc that melts and fuses the stainless steel pieces together. MIG welding offers excellent control, high welding speeds, and good weld quality. It is commonly used in various industries, including automotive, construction, and manufacturing, where stainless steel’s corrosion resistance and strength are essential. Proper equipment, technique, and knowledge of stainless steel properties are crucial for achieving durable and high-quality welds.

When considering stainless steel versus carbon steel, it’s important to understand their differences. Stainless steel is known for its corrosion resistance and durability, making it ideal for various applications. Stainless steel suppliers offer a wide range of products with different grades and finishes to meet specific needs. On the other hand, carbon steel is often chosen for its strength and affordability. However, it is more susceptible to corrosion and requires protective coatings. Ultimately, the choice between stainless steel and carbon steel depends on factors such as the intended use, budget, and environmental conditions. Consulting with reputable stainless steel suppliers can help determine the best material for your specific requirements.

Master the art of drilling through stainless steel with precision. Discover proven techniques, specialized tools, and expert guidance to achieve flawless results. Unlock the secrets of this challenging task and conquer stainless steel with confidence.

Stainless steel is a good conductor of electricity. It has metallic bonding, which allows electrons to move freely within its structure. The presence of metallic elements, such as iron and chromium, contributes to its conductivity. However, the electrical conductivity of stainless steel can vary depending on its composition and specific alloy.

Stainless steel can be painted using specialized techniques and coatings designed for metal surfaces.

You can use metal on stainless steel. Stainless steel is a type of metal that is highly resistant to corrosion and oxidation. It is commonly used in various applications where strength and durability are required. Metal tools, fasteners, and equipment can be safely used on stainless steel without causing any significant damage or adverse effects.

How to weld stainless steel?The steps in welding stainless steel include preparing tools and materials, cleaning the work surface, selecting the appropriate welding method and parameters, performing the welding, checking the quality of the weld, and cleaning and finishing the weld. During the welding process, attention needs to be paid to the control of shielding gas and welding speed, as well as preheating before welding and heat treatment after welding.

No, stainless steel does not typically turn green. Its corrosion-resistant properties prevent the formation of green oxidation commonly seen on other metals.

Use a cutting tool, such as a metal shear or a plasma cutter, to make precise cuts on stainless steel sheets. Ensure proper safety measures and follow recommended techniques for clean and accurate results.

Stainless steel itself does not have the ability to waterproof, but it can be added by special alloy elements and surface treatment, improve its waterproof performance.

Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours