309 stainless steel is widely utilized in various high-temperature environments due to its exceptional heat resistance and oxidation resistance. Some typical applications of 309 stainless steel in high-temperature settings include:

Heat Treatment Furnaces: 309 stainless steel is commonly used to construct components and fixtures within heat treatment furnaces, where temperatures can reach extreme levels. Its ability to withstand prolonged exposure to elevated temperatures without significant deformation or degradation makes it ideal for this application.

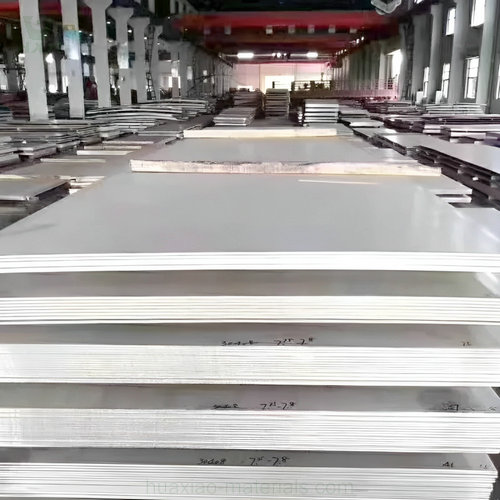

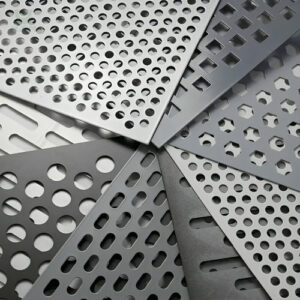

Heat Exchangers: In industries where heat transfer is crucial, such as petrochemical, chemical processing, and power generation, 309 stainless steel is employed in the fabrication of heat exchanger tubes and plates. Its resistance to high temperatures and corrosion makes it suitable for handling hot fluids and gases.

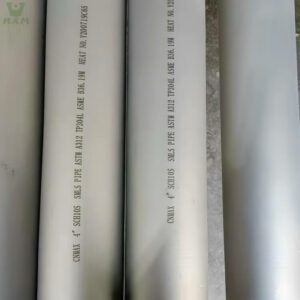

Boiler Tubes and Superheaters: 309 stainless steel is often utilized in the construction of boiler tubes and superheaters in power plants and industrial facilities. Its ability to maintain mechanical strength and resist scaling under high-temperature steam conditions is vital for these applications.

Catalytic Cracking Units: In the petrochemical industry, catalytic cracking units operate at extremely high temperatures. 309 stainless steel is employed to fabricate critical components within these units due to its ability to withstand harsh operating conditions.

High-Temperature Ovens and Kilns: 309 stainless steel is favored for constructing the inner linings, racks, and fixtures of high-temperature ovens and kilns used in industries like ceramics, glass, and metallurgy.

Muffle Furnaces: Muffle furnaces, used for applications like heat treatment, sintering, and annealing, rely on 309 stainless steel for their inner chamber walls and heat-resistant components.

Aerospace Applications: In the aerospace industry, 309 stainless steel is employed for exhaust systems, combustion chambers, and other components where high-temperature resistance is critical.

Chemical Processing Equipment: 309 stainless steel finds use in various chemical processing equipment, such as reactors and furnaces, where exposure to aggressive chemicals and high temperatures is common.

Refining Units: Refineries use 309 stainless steel in units like cracking, coking, and distillation, where high-temperature corrosion resistance is essential.

Welding Filler Material: 309 stainless steel is also used as a welding filler material for dissimilar metal welding applications, especially when joining stainless steel to carbon steel in high-temperature environments.

Overall, the exceptional high-temperature performance and oxidation resistance of 309 stainless steel make it a preferred choice for a wide range of industrial applications where exposure to extreme heat and aggressive conditions is expected.