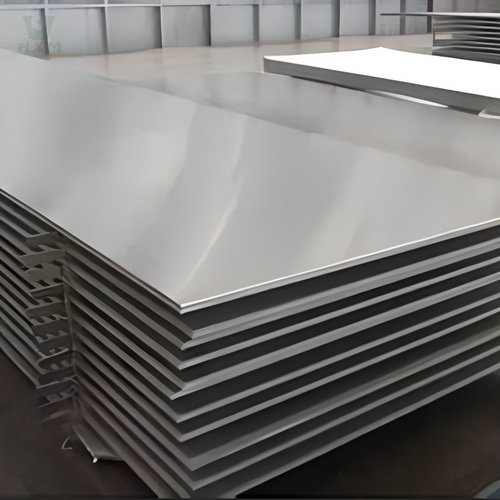

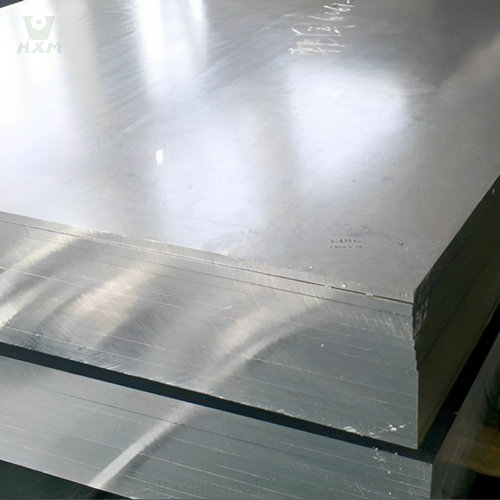

15-5PH stainless steel

15-5PH stainless steel is a precipitation-hardening alloy with 15% chromium, 5% nickel, and 3% copper. It delivers high strength, corrosion resistance, and is used in aerospace, nuclear, and chemical processing applications.

15-5PH stainless steel is a precipitation-hardening alloy with 15% chromium, 5% nickel, and 3% copper. It delivers high strength, corrosion resistance, and is used in aerospace, nuclear, and chemical processing applications.

15-5PH stainless steel is a precipitation-hardening stainless steel known for its combination of high strength, corrosion resistance, and excellent mechanical properties. The composition of 15-5PH stainless steel typically includes the following elements:

| Element | Composition Range |

|---|---|

| Chromium (Cr) | 14.0 – 15.5% |

| Nickel (Ni) | 3.5 – 5.5% |

| Copper (Cu) | 2.5 – 4.5% |

| Manganese (Mn) | ≤ 1.0% |

| Silicon (Si) | ≤ 1.0% |

| Phosphorus (P) | ≤ 0.040% |

| Sulfur (S) | ≤ 0.030% |

| Carbon (C) | ≤ 0.07% |

| Nitrogen (N) | ≤ 0.15% |

| Iron (Fe) | Remaining balance |

This composition defines the elemental makeup of 15-5PH stainless steel, which contributes to its unique combination of mechanical properties and performance characteristics.

| Performance Characteristic | Description |

|---|---|

| High Strength | Offers exceptional strength, suitable for applications requiring structural integrity under heavy loads. |

| Corrosion Resistance | Provides good corrosion resistance in mild atmospheres, fresh water, and some corrosive chemicals. |

| Precipitation Hardening | Can be significantly hardened through heat treatment processes, enhancing mechanical properties. |

| Heat Resistance | Exhibits good heat resistance, making it suitable for elevated temperature applications. |

| Magnetic Properties | Possesses magnetic properties due to its martensitic structure from precipitation hardening. |

| Weldability | Can be welded using standard processes, though post-weld heat treatment may be necessary for property restoration. |

| Formability | Offers reasonable formability and can be machined using standard techniques. |

| Applications | Commonly used in aerospace components, chemical processing equipment, and applications requiring high-strength fasteners. |

| Stress Corrosion Cracking | Susceptible to stress corrosion cracking (SCC) under specific conditions. |

| Aging | Mechanical properties can be enhanced through aging, achieving a balance of strength and toughness. |

High Strength: 15-5PH stainless steel offers exceptional strength, making it suitable for applications where structural integrity under heavy loads is essential.

Corrosion Resistance: This alloy provides good corrosion resistance in various environments, including mild atmospheres, fresh water, and some corrosive chemicals. It is, however, less resistant to pitting and crevice corrosion compared to austenitic stainless steels.

Precipitation Hardening: 15-5PH stainless steel is known for its ability to be precipitation-hardened. This means that its mechanical properties can be significantly enhanced through heat treatment processes.

Heat Resistance: It exhibits good heat resistance, making it suitable for applications involving elevated temperatures, such as in aerospace and industrial equipment.

Magnetic Properties: 15-5PH stainless steel is magnetic due to its martensitic structure resulting from the precipitation hardening process.

Weldability: While not as readily weldable as austenitic stainless steels, 15-5PH can be welded using standard processes. However, post-weld heat treatment may be necessary to restore its mechanical properties.

Formability: It offers reasonable formability and can be machined using standard techniques.

Applications: 15-5PH stainless steel is commonly used in aerospace components, chemical processing equipment, nuclear reactor components, and applications requiring high-strength fasteners.

Stress Corrosion Cracking: 15-5PH stainless steel is susceptible to stress corrosion cracking (SCC) under certain conditions. Care should be taken to avoid SCC-prone environments.

Aging: The mechanical properties of 15-5PH stainless steel can be enhanced through aging, providing a balance of strength and toughness.

In summary, 15-5PH stainless steel is valued for its exceptional strength, corrosion resistance, and precipitation-hardening capabilities. It finds its place in various industries where a combination of these properties is required for demanding applications.

15-5PH stainless steel finds its utility in various industries due to its unique blend of mechanical properties and corrosion resistance. Some of its typical applications across different sectors include:

Aerospace: 15-5PH is frequently employed in aerospace applications such as aircraft components, structural parts, landing gear, and fasteners. Its high strength and resistance to corrosive environments make it suitable for these critical applications.

Chemical Processing: This stainless steel is used in chemical processing equipment where resistance to corrosive chemicals and high temperatures is crucial. It is found in pumps, valves, reactor vessels, and piping systems.

Oil and Gas Industry: Components exposed to demanding offshore and onshore environments, such as valves, fittings, and pipelines, benefit from 15-5PH’s corrosion resistance and mechanical strength.

Pharmaceuticals: The pharmaceutical industry uses 15-5PH stainless steel for equipment that requires both corrosion resistance and cleanliness, such as vessels, containers, and processing machinery.

Food Processing: In food processing, where hygiene and corrosion resistance are paramount, 15-5PH is utilized in equipment like conveyors, mixers, and storage tanks.

Pulp and Paper: The pulp and paper industry employs 15-5PH in equipment exposed to the corrosive environment of chemical pulping, such as digesters, screens, and washers.

Nuclear Power: Components within nuclear reactors, including reactor vessels and cooling systems, benefit from 15-5PH’s resistance to high temperatures and corrosive conditions.

Medical Devices: Due to its biocompatibility, 15-5PH stainless steel is used in medical applications such as surgical instruments, implants, and orthopedic devices.

Marine Industry: Marine equipment, including shipbuilding and offshore platforms, often incorporates 15-5PH stainless steel for its ability to withstand saltwater corrosion.

Automotive: 15-5PH may be used in automotive applications where a combination of high strength and corrosion resistance is required, such as in exhaust systems.

Industrial Equipment: Various industrial equipment, including machinery parts, gears, and shafts, benefit from 15-5PH’s mechanical properties in demanding environments.

Defense and Military: Firearms, ammunition, and military vehicle components utilize 15-5PH for its strength and corrosion resistance.

In summary, 15-5PH stainless steel is versatile and widely used across industries that demand a balance between strength, corrosion resistance, and reliability in challenging environments. Its applications range from aerospace to medical devices, reflecting its adaptability to various specialized needs.

15-5PH stainless steel, 17-4PH stainless steel, and 13-8PH stainless steel are all part of the precipitation-hardening (PH) stainless steel family. While they share similarities, they also exhibit differences that make them suitable for various applications. Let’s compare these three grades:

In summary, while all three grades are precipitation-hardening stainless steels with strengths and corrosion resistance, their specific composition and heat-treatment characteristics differentiate them. The choice between 15-5PH, 17-4PH, and 13-8PH depends on the specific requirements of the application, including the desired balance of mechanical properties, corrosion resistance, and other factors.

Heat treatment and aging processes play a crucial role in achieving the desired mechanical properties in 15-5PH stainless steel. The specific steps and conditions depend on the target properties and application requirements. Here are the key considerations for heat treatment and aging processes to optimize the properties of 15-5PH stainless steel:

In conclusion, achieving optimal properties in 15-5PH stainless steel through heat treatment and aging processes requires careful consideration of parameters, testing, and validation. By controlling the solution annealing and aging steps, it’s possible to tailor the material’s mechanical properties to meet the specific demands of the application.

Components made of 15-5PH stainless steel are known for their excellent combination of strength, corrosion resistance, and toughness. To ensure the longevity and optimal performance of these components, there are several specific maintenance requirements and considerations to keep in mind:

By following these maintenance requirements and considerations, you can extend the lifespan of components made of 15-5PH stainless steel and ensure they continue to perform effectively in their intended applications.

Selecting reliable suppliers for 15-5PH stainless steel products is essential to ensure the quality, performance, and availability of the materials. Here are the key factors to consider when evaluating potential suppliers:

1. Quality Assurance:

2. Material Certification:

3. Industry Experience:

4. Product Range and Availability:

5. Capacity and Production Capability:

6. Reputation and Reviews:

7. Customization Capability:

8. Technical Support:

9. Compliance with Standards:

10. Lead Times and Delivery:

11. Pricing and Cost Transparency:

12. Logistics and Packaging:

13. Sustainability and Ethics:

14. Customer Service:

15. Long-Term Partnership Potential:

16. References and Site Visits:

By thoroughly considering these factors and conducting thorough research, you can select a reputable supplier for 15-5PH stainless steel products that aligns with your quality, performance, and delivery requirements.

You might also enjoy

Mastering PVD Stainless Steel Coatings: A Guide to Durability, Aesthetics, and Applications

Read More »Copyright@2023 Huaxiao Metal Corporation Limited . All rights are reserved

WhatsApp us

Feel free to contact us!

If you need our products, please leave us a message with the specific specifications and quantity through the window on the right!

Reply within 24 hours