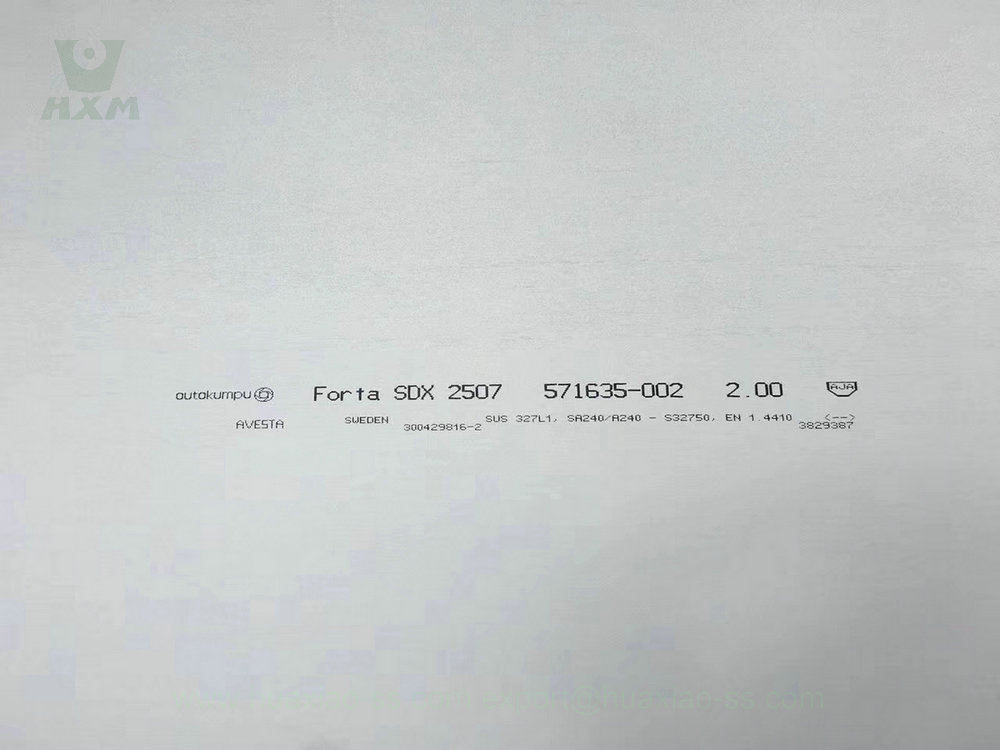

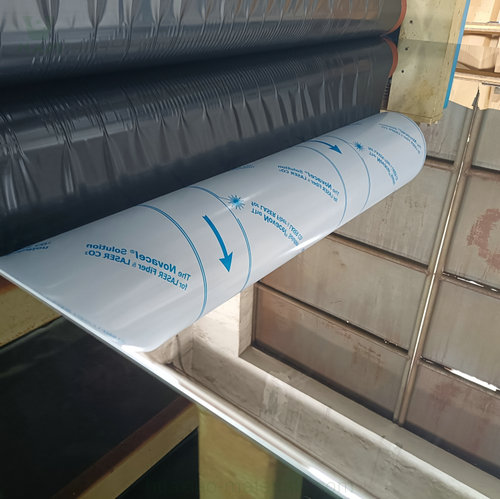

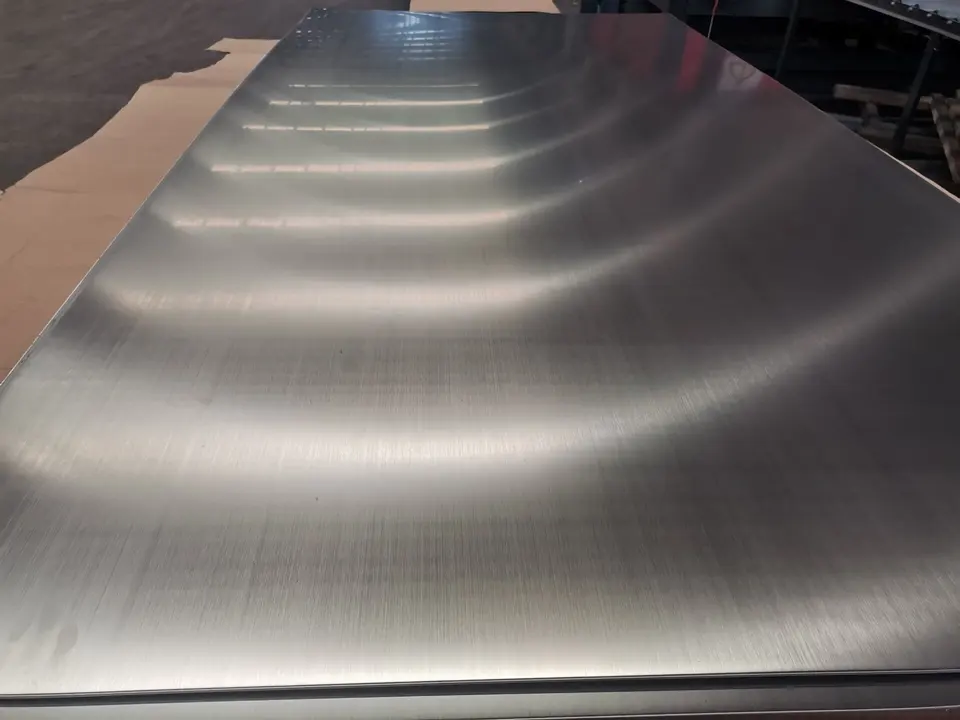

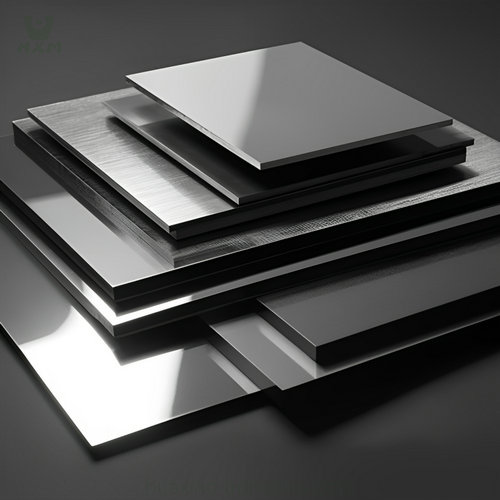

-2507 Cold Rolled Stainless Steel coil, Cold rolled 2507 coil, 2507 CRC.

- Thickness: 0.2mm – 8.0mm

- Width: 600mm – 2000mm,

- the narrowed products pls check in strip products

- Max coil weight: 25MT

- Coil ID: 508mm, 610mm

- Finish: 2B

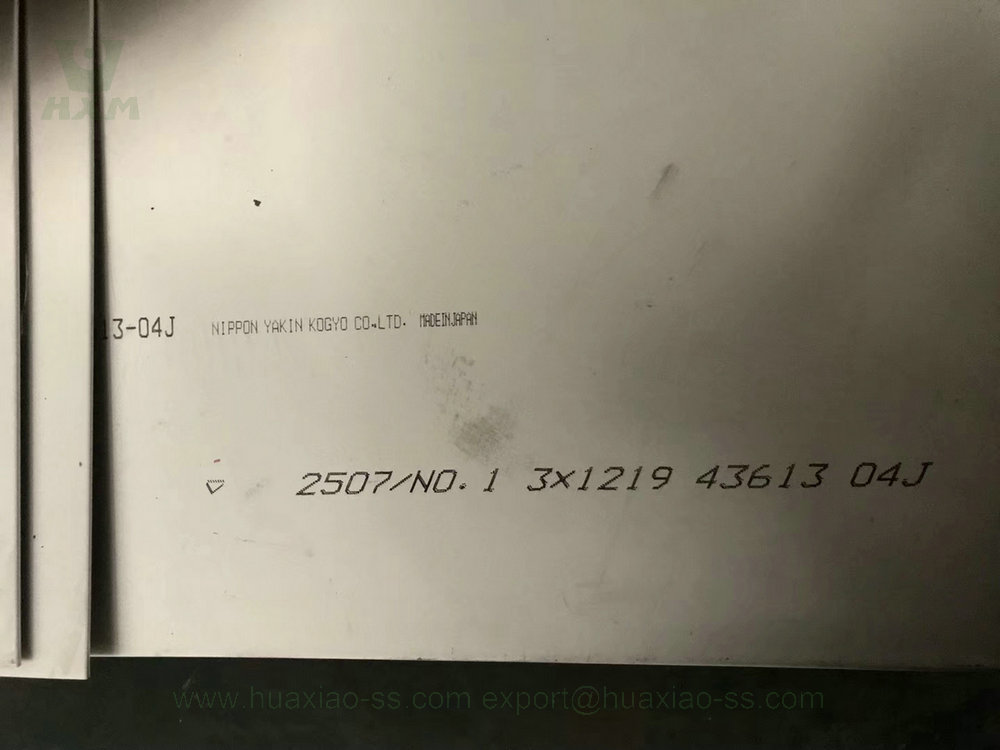

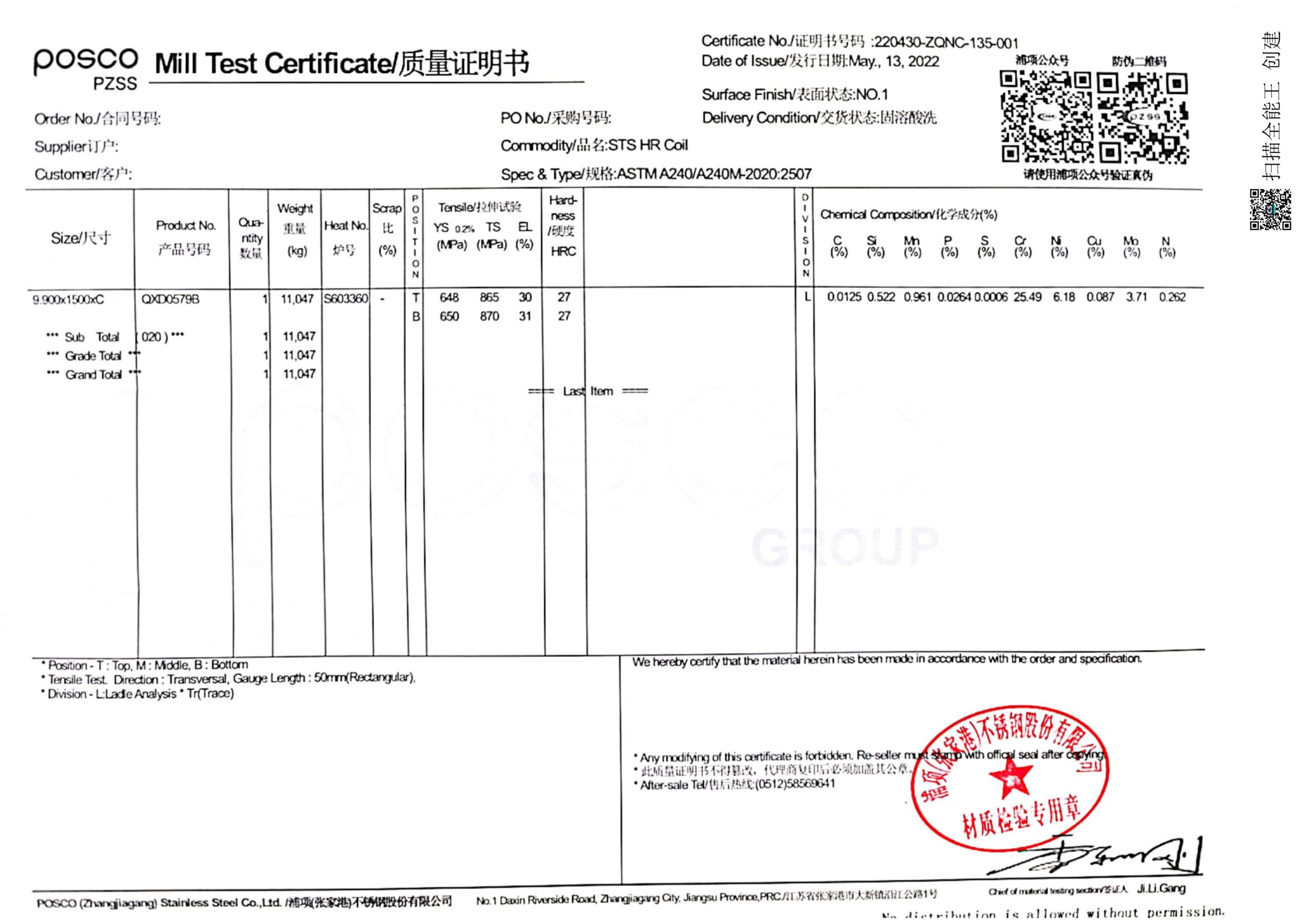

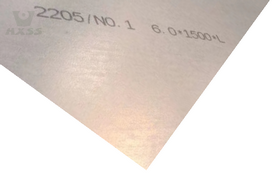

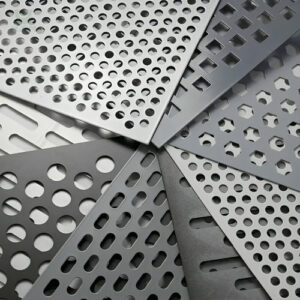

-2507 Hot Rolled Stainless Steel coil, Hot Rolled 2507 coil, 2507 HRC.

- Thickness: 1.2mm – 16mm

- Width: 600mm – 2000mm,

- the narrower products please check in strip products

- Max coil weight: 40MT

- Coil ID: 508mm, 610mm

- Finish: NO.1